An auxiliary agent for inhibiting the diffusion of tannin in wood and its application method

A technology of wood and additives, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor inhibition effect, closed tannin, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

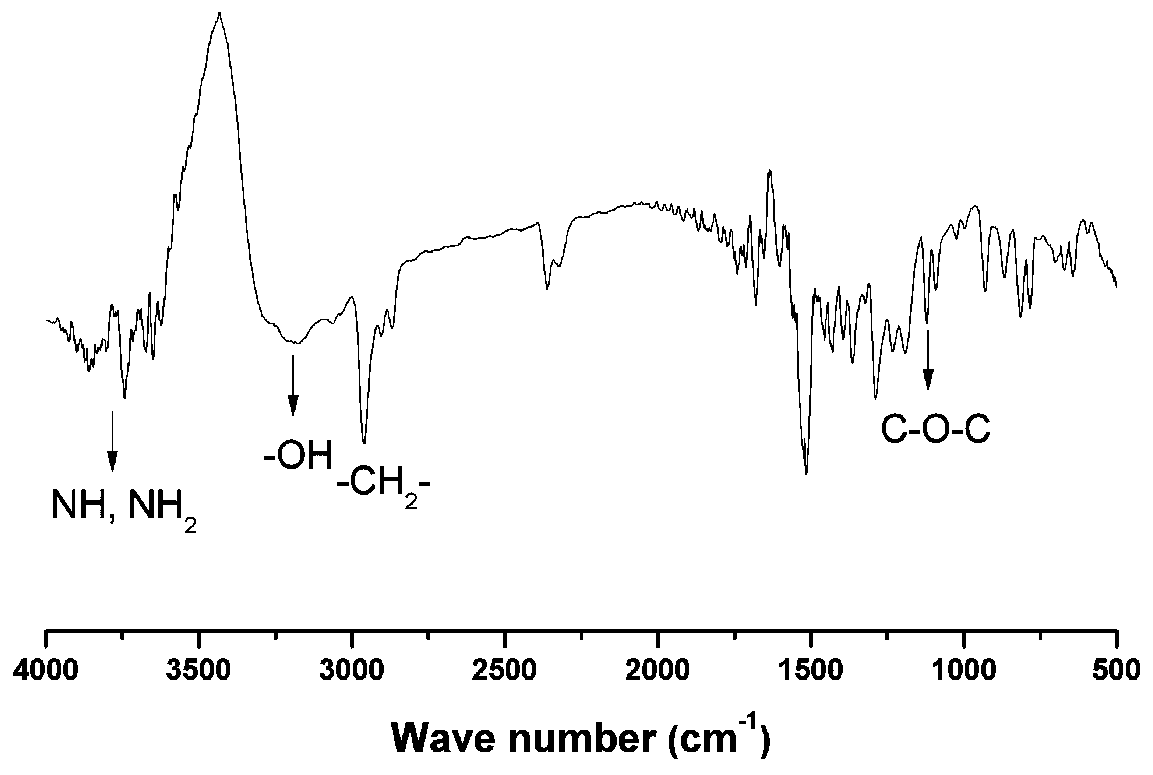

[0039]Add 9.68g of ethanol, polyetheramine D230 (2.41g, 0.011mol) and ethylene glycol glycidyl ether (1.74g, 0.010mol) into the reactor, react at 60°C for 12 hours under stirring conditions, cool down, and filter An ethanol solution of the organic amine polymer is obtained. figure 1 It is the infrared spectrum of ethylene glycol glycidyl ether-polyether amine D230 condensation polymer, which shows that the organic condensate polymer has been successfully synthesized. Precipitate this solution in petroleum ether or anhydrous ether, collect the precipitate, and dry it in a vacuum oven to constant weight to obtain an organic amine polymer.

[0040] The organic condensate polymer is mixed with ethanol or absolute ethanol according to the mass ratio of 3:7, and dissolved. Add 5% calcium chloride (0.89g), stir evenly, and filter to obtain an auxiliary agent for inhibiting the diffusion of tannin for water-based woodware coating.

[0041] 40 parts of water-based acrylate resin, 50...

Embodiment 2

[0048] Add 6.23g of ethanol, diethylene glycol glycidyl ether (1.09g, 0.005mol) and isophorone diamine (1.70g, 0.01mol) into the reactor, add catalyst mass fraction 3% of 1,8 - Diazabicycloundec-7-ene (0.28g), reacted at 15°C under stirring conditions for 48 hours, and filtered to obtain an ethanol solution of the organic condensate polymer. Precipitate this solution in petroleum ether or anhydrous ether, collect the precipitate, and dry it in a vacuum oven to constant weight to obtain an organic amine polymer.

[0049] The organic condensate polymer is mixed with ethanol or absolute ethanol according to the mass ratio of 3:7, and dissolved. Add 3% calcium chloride (0.23g), stir evenly, and filter to obtain the auxiliary agent for inhibiting the diffusion of tannin for water-based woodware coating.

[0050] 50 parts of water-based alkyd resin, 42 parts of ethanol, and 8 parts of anti-tannin diffusion aid. After mixing the above components evenly, spray on wood with a water co...

Embodiment 3

[0056] In the reactor, 2,2'-diaminotriethyl ether and 1,6-hexanediol diglycidyl ether are fed according to the molar ratio of 1.01:1.00, and the mass concentration of the above mixture is adjusted to 67% with absolute ethanol, and added Triethylamine with a mass fraction of 3% was reacted at 50° C. under stirring for 6 hours. Cool down and filter to obtain an ethanol solution of the organic amine polymer. Precipitate this solution in petroleum ether or anhydrous ether, collect the precipitate, and dry it in a vacuum oven to constant weight to obtain an organic amine polymer.

[0057] The organic condensate polymer is mixed with ethanol or absolute ethanol according to the mass ratio of 3:7, and dissolved. Calcium chloride with a mass fraction of 2% is added, stirred evenly, and filtered to obtain an auxiliary agent for inhibiting the diffusion of tannin for water-based woodware coating.

[0058] 45 parts of water-based acrylic resin, 46 parts of absolute ethanol, and 9 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com