Epoxy glue binder for encapsulating of flexible screen

A technology of epoxy glue and adhesive, which is applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problems of unsuitable flexible screen packaging bonding, poor storage stability, and high curing temperature, so as to avoid storage Poor stability, low hygroscopicity, and low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, the specific raw materials required for the preparation of the epoxy adhesive of the present invention are as follows:

[0048] An epoxy adhesive for flexible screen packaging, in parts by weight, comprising:

[0049] 40-60 parts of epoxy resin;

[0050] 5-10 parts of epoxy diluent;

[0051] 30-50 parts of curing agent;

[0052] 0.1-2 parts of photobase generator;

[0053] 0.1-2 parts of stabilizer;

[0054] 5-10 parts of toughening agent;

[0055] Filling 20-40 parts;

[0056] Auxiliary 0.2-2 parts.

[0057] A preferred technical solution of this embodiment: the epoxy resin includes a mixture of one or more of bisphenol A epoxy resin and bisphenol F epoxy resin.

[0058] A preferred technical solution of this embodiment: the epoxy diluent includes a mixture of one or more of oxetane and aliphatic glycidyl ether.

[0059] A preferred technical solution of this embodiment: the curing agent includes a mixture of one or more of the following secondary m...

Embodiment 2

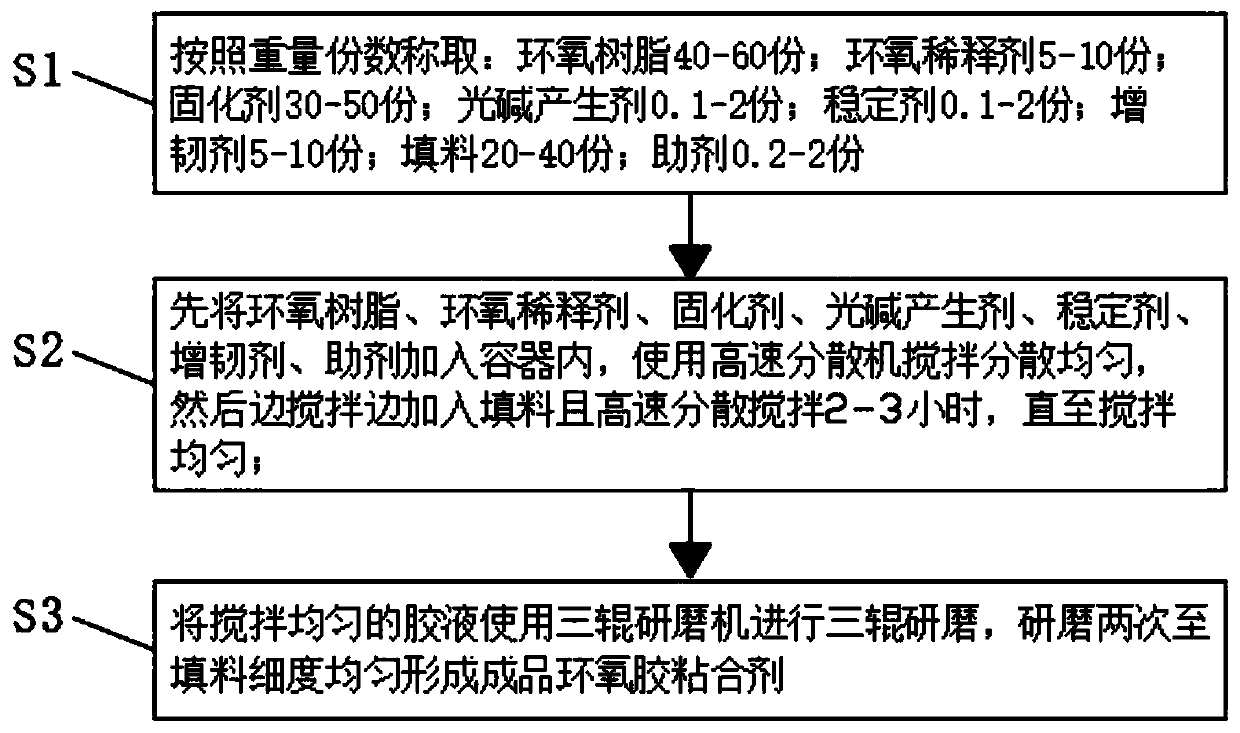

[0075] Please refer to the attached figure 1 , the preparation method of a kind of epoxy glue adhesive of the present invention, this preparation method comprises the following steps:

[0076] Step 1: Weighing according to parts by weight: 40-60 parts of epoxy resin; 5-10 parts of epoxy diluent; 30-50 parts of curing agent; 0.1-2 parts of photobase generator; 0.1-2 parts of stabilizer; 5-10 parts of toughening agent; 20-40 parts of filler; 0.2-2 parts of auxiliary agent;

[0077] Step 2: Add epoxy resin, epoxy diluent, curing agent, photobase generator, stabilizer, toughening agent, and auxiliary agent into the container, use a high-speed disperser to stir and disperse evenly, and then add filler while stirring. Disperse and stir at high speed for 2-3 hours until the mixture is uniform;

[0078] Step 3: Use a three-roller grinder to perform three-roll grinding on the uniformly stirred glue solution, and grind twice until the filler fineness is uniform to form a finished epox...

Embodiment 3

[0081] Weigh the following components:

[0082] Epoxy resin: 40g (bisphenol A epoxy resin of brand EXA-850CRP);

[0083] Epoxy diluent: 5g (oxetane of brand CURALITE OX);

[0084] Curing agent: 50g (mercaptan of grade PE1);

[0085] Catalyst: 0.1g (photobase generator of brand WPBG-018);

[0086] Stabilizer: 0.1g (the stabilizer of brand Hostanox P-EPQ);

[0087] Toughening agent: 5g (polyol of grade CAPA4101);

[0088] Filler: 20g (19g of talc powder of brand HTP1, 1g of fumed silica of brand H20);

[0089] Auxiliary: 0.2g (0.1g of defoamer of brand BYK067A; 0.1g of dispersant of brand BYK9076).

[0090] According to the preparation method in Example 2, add materials, mix, stir and disperse, and three-roll grinding, until it is uniform, then degassing and packaging to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com