A kind of electrofusion additive manufacturing x100 steel grade tee pipe fitting material and its use method

A three-way pipe fitting and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, to achieve the effects of promoting travel, reducing carbon equivalent, and satisfying impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A material for X100 steel grade tee pipe fittings manufactured by electrofusion and additive manufacturing, in terms of mass percentage, comprising the following proportions:

[0037] C: 0.06%; Mn: 0.70%; Si: 0.20%; Cr: 1.5%; Mo: 0.5%; Ni: 0.05%; Nb: 0.004%; Cu: 0.02%; Ti: 0.01%; , P≤0.010%; S≤0.005%; the rest is Fe.

Embodiment 2

[0039] A material for X100 steel grade tee pipe fittings manufactured by electrofusion and additive manufacturing, in terms of mass percentage, comprising the following proportions:

[0040] C:0.10%;Mn:1.0%;Si:0.40%;Cr:2.5%;Mo:1.0%;Ni:0.10%;Nb:0.007%;Cu:0.05%;Ti:0.016%;B:≤0.005% , P≤0.010%; S≤0.005%; the rest is Fe.

Embodiment 3

[0042] A material for X100 steel grade tee pipe fittings manufactured by electrofusion and additive manufacturing, in terms of mass percentage, comprising the following proportions:

[0043] C: 0.08%; Mn: 0.85%; Si: 0.30%; Cr: 2%; Mo: 0.75%; Ni: 0.075%; Nb: 0.0055%; Cu: 0.035%; Ti: 0.013%; , P≤0.010%; S≤0.005%; the rest is Fe.

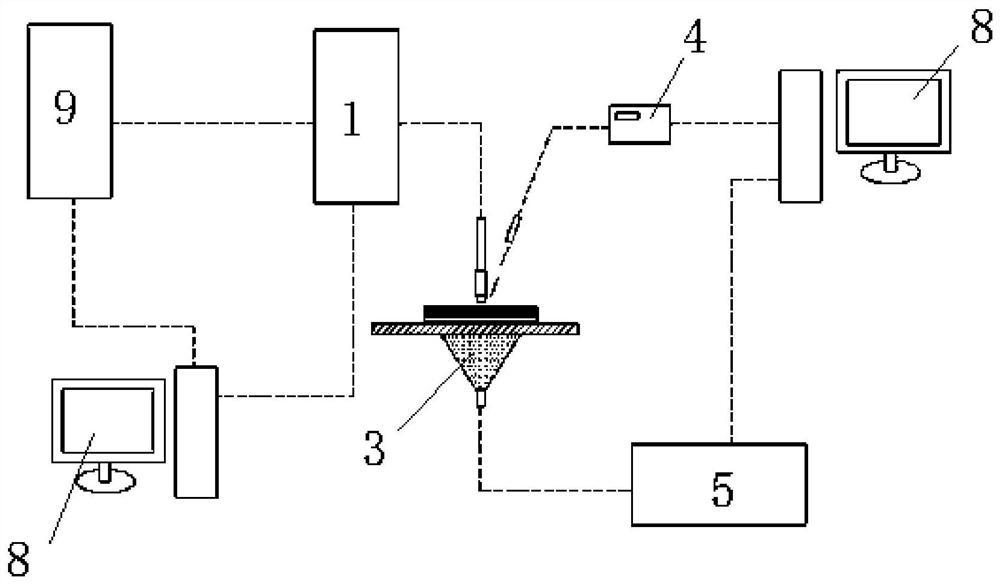

[0044] The invention discloses a method for using electric melting and additive manufacturing of X100 steel grade tee pipe fitting materials, which adopts the electric melting and additive manufacturing technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com