Semi-assembled composite bridge pier and construction method thereof

A semi-assembly and bridge pier technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as uneven distribution of stress and strain at joints, poor mechanical and seismic performance of bridge piers, long construction period, etc., to achieve automatic Strong reset ability, convenient and fast construction, and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

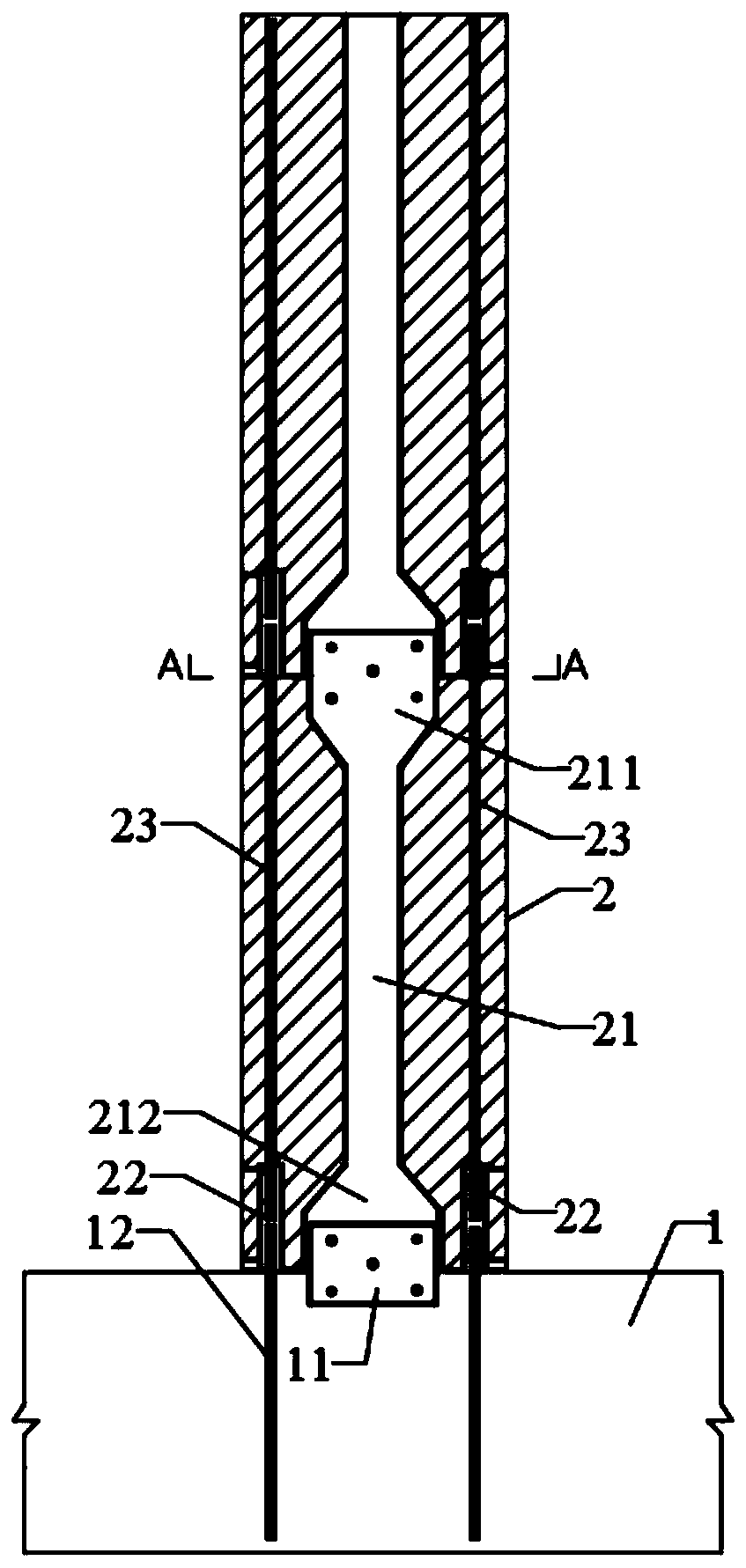

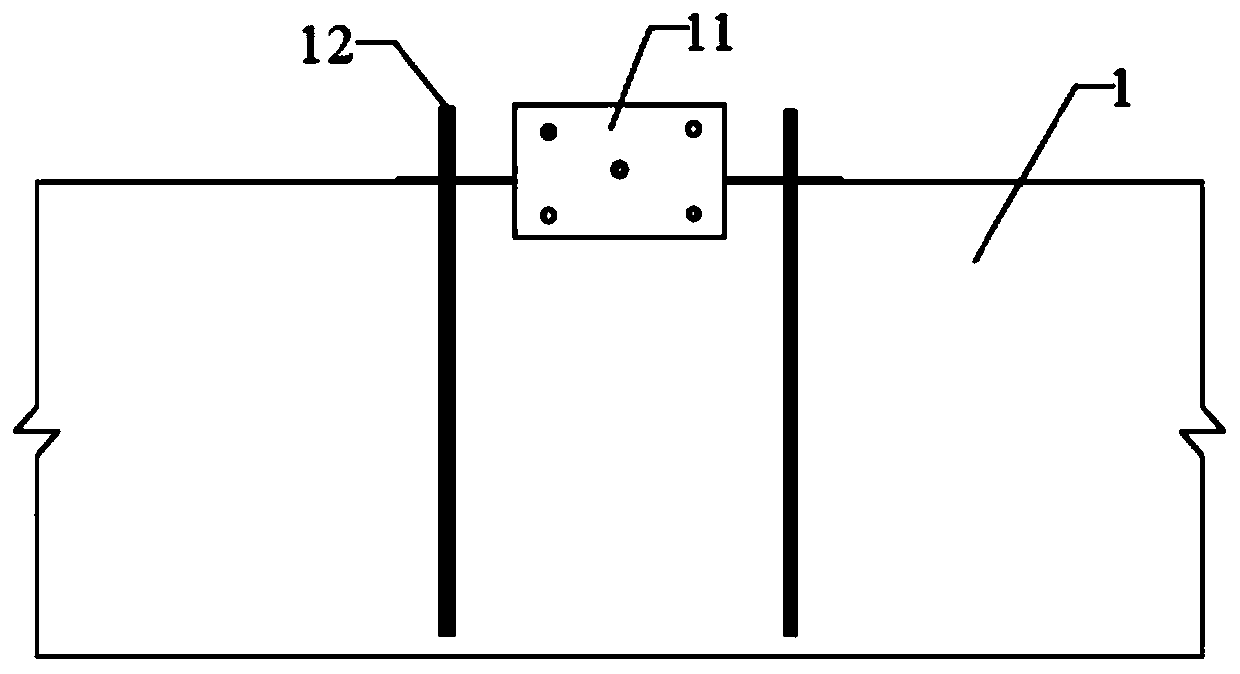

[0049] A semi-fabricated composite pier, comprising a prefabricated cap 1 and a plurality of prefabricated pier segments 2;

[0050] The prefabricated cap 1 is set on the foundation, the top center of the prefabricated cap 1 is provided with a cap hollow steel pipe 11, the side wall of the prefabricated hollow steel pipe is provided with a plurality of reserved holes, and the prefabricated hollow steel pipe The top surface of the surrounding prefabricated platform 1 is evenly provided with a plurality of prefabricated steel bars 12 for the platform;

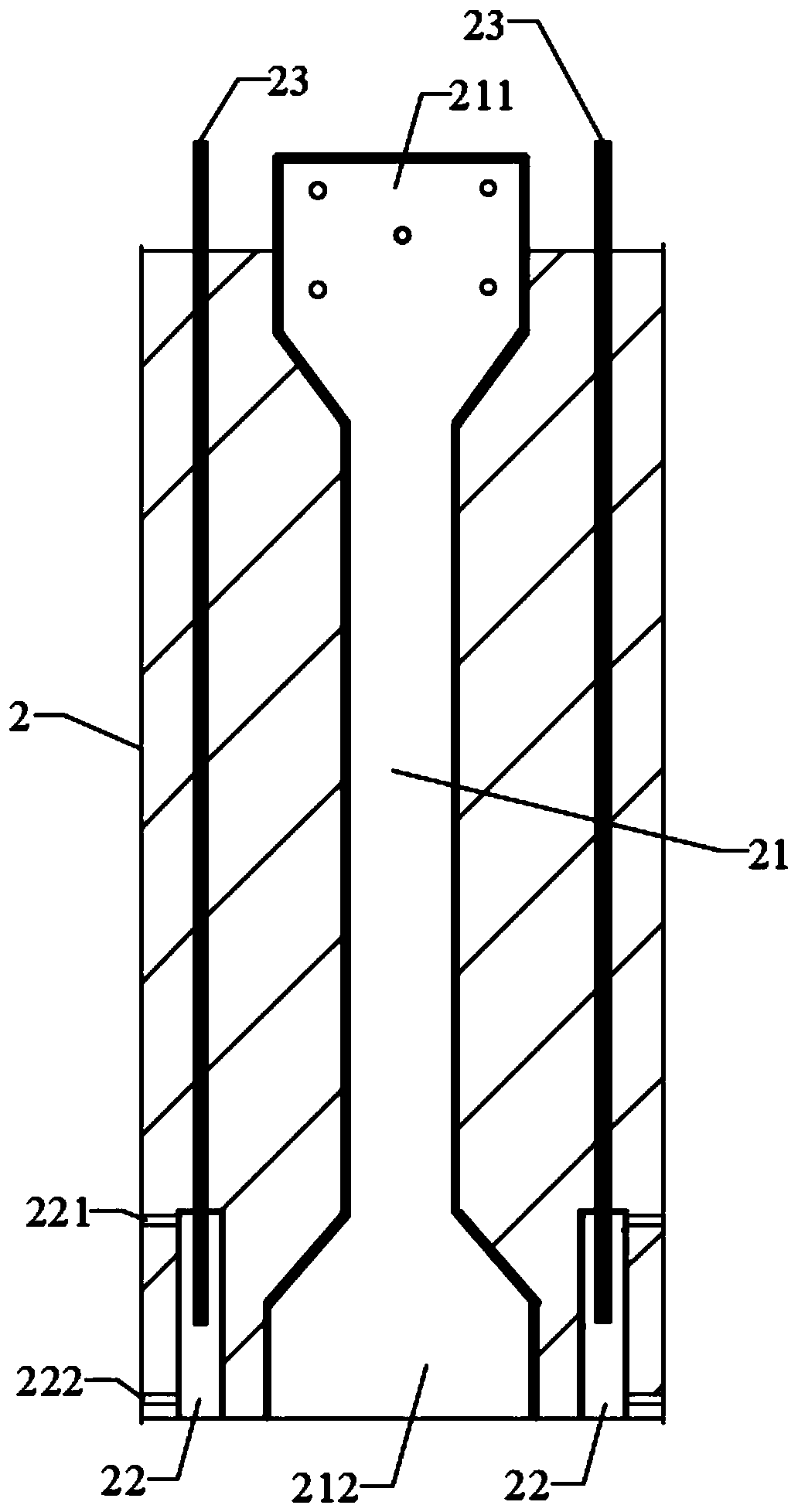

[0051] The prefabricated bridge pier section 2 is cylindrical and vertically connected to the top surface of the prefabricated bridge pier. The inside of the prefabricated bridge pier section 2 is provided with a pier hollow steel pipe 21, and the bottom end of the pier hollow steel pipe 21 is provided with a lower connection part 212, the lowest end of the lower connecting portion 212 is flush with the bottom surface of the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com