Heavy metal enriching plant treatment system

A technology of enrichment plants and treatment system, which is applied in the field of incineration of heavy metal enrichment plants, to achieve the effects of ensuring drying efficiency, reducing water consumption and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described in detail through the accompanying drawings and embodiments. Through these descriptions, the characteristics and advantages of the present invention will become clearer. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

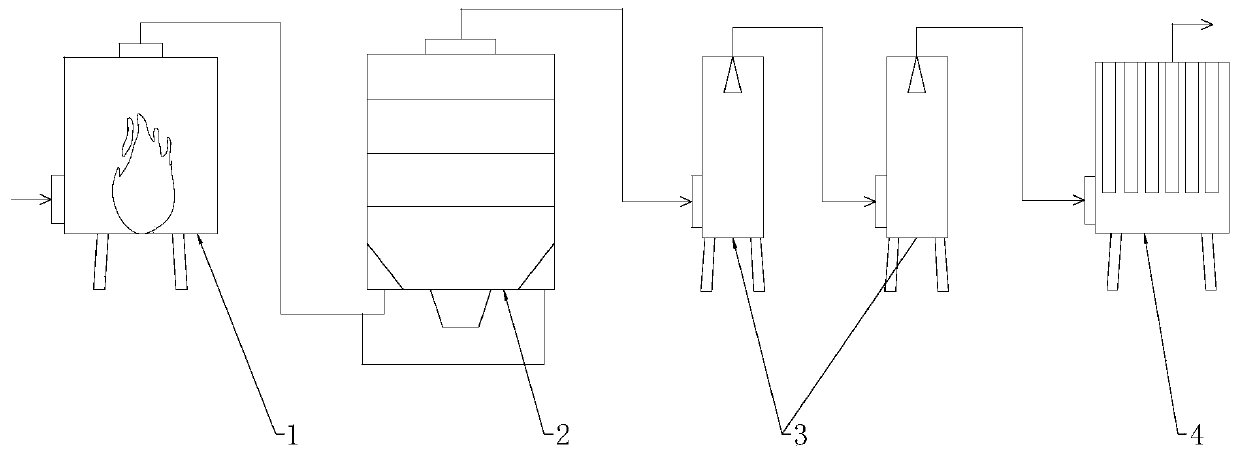

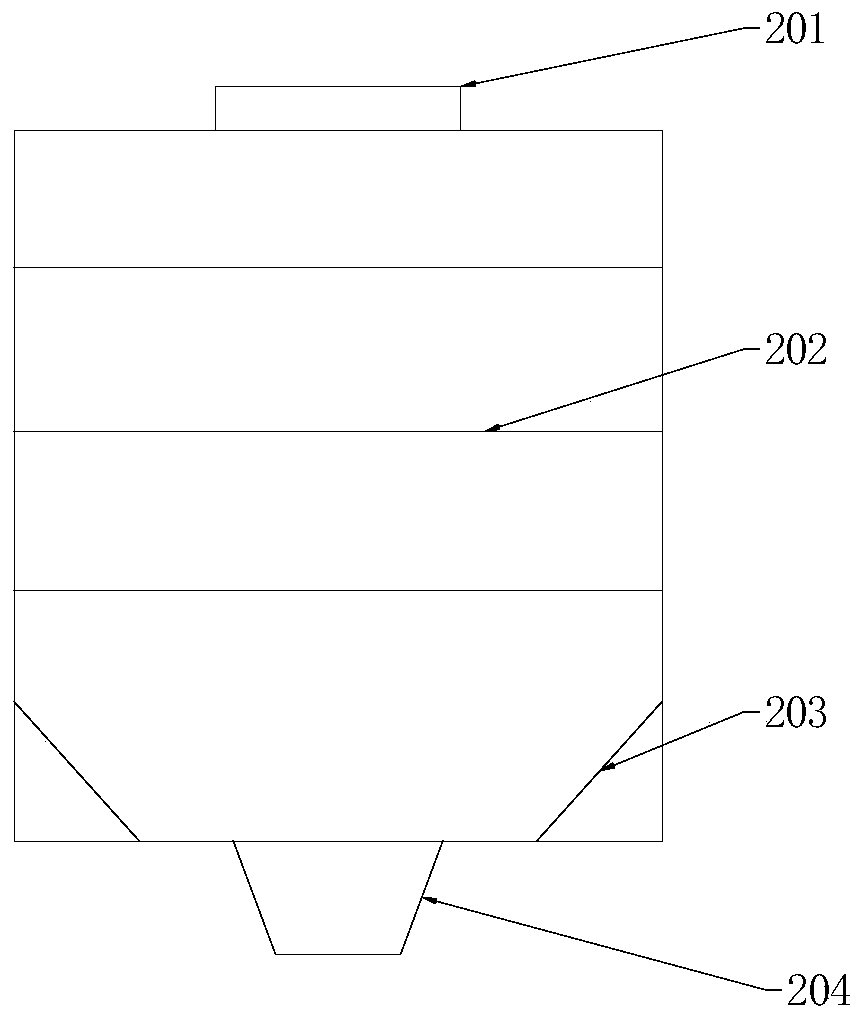

[0023] Such as Figure 1-2 As shown, the heavy metal-enriched plant treatment system of this embodiment includes an incinerator 1, a pretreatment tank 2, a two-stage spray tower 3, and a bag filter 4. The exterior of the pretreatment tank is covered with a layer of insulation material to ensure the insulation effect and save energy. The pretreatment tank is provided with an air outlet 201 at the top, an air inlet 203 and an ash hopper 204 at the bottom, and a multi-layer support net 202 is provided in the pretreatment tank. The support net is sealed with the pretreatment tank or assembled by sliding The way of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com