Preparation method of an ordered mesoporous metal oxide@carbon lithium-ion battery anode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of battery volume waste, excessively large hollow structure pore size, and difficult to control carbon coating, and achieve low production costs. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

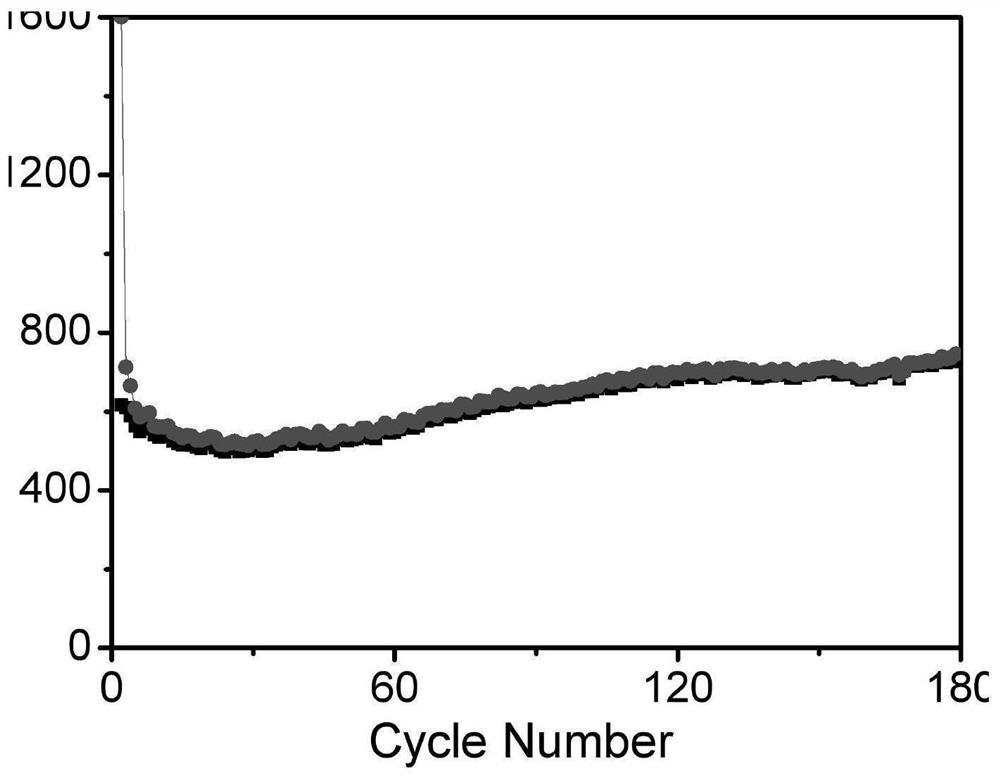

[0032] Example 1, an ordered mesoporous SnO in this example 2 The preparation method of @C lithium-ion battery negative electrode material is characterized in that said preparation method is carried out according to the following steps:

[0033] Step 1. Dissolve 18g of ferric oleate in 100ml of 1-octadecene (ODE) in a three-necked flask, disperse evenly by ultrasonic (ultrasonic frequency 20KHz) for 30min, add 2000ul of oleic acid, place in a heating mantle, and stir at 500rpm for 10min ;

[0034] Step 2. Set the heating mantle at 5°C min -1 Heat to 320°C and keep it warm for 45 minutes;

[0035] Step 3. Wash the product of step 2 with water to remove the by-product NaCl, wash with acetone and n-hexane with a volume ratio of 1:1, and centrifuge three times at a speed of 10500 rpm to obtain monodisperse Fe 3 o 4 nanoparticles;

[0036] Step 4, the above obtained Fe 3 o 4 Nanoparticles are dispersed in n-hexane again, ultrasonic (ultrasonic frequency 20KHz) for 10min, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com