Combination polyether silicone defoamer for fermentation and preparation method thereof

A technology of polyether silicone and defoaming agent, which is applied in the field of food additives, can solve the problem of poor defoaming and foam suppression effect and stability, demulsification and stratification, defoaming and foam suppression effect and stability that are difficult to satisfy sodium glutamate fermentation. Use requirements and other issues to achieve the effect of improving stability, improving foam suppression performance, and uniform distribution of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the combined polyether silicone defoamer for fermentation of the present invention, the specific steps are as follows:

[0043] (1) Preparation of cross-linked polyacrylic acid resin blending agent: dissolve 0.1-0.5 parts of alkyl acrylate cross-linked resin in 40-50 parts of deionized water, stir well and add 0.1-0.3 parts of triethanolamine to obtain The pH value of the cross-linked polyacrylic acid resin blending agent solution is 7-8;

[0044] (2) First put 1-3 parts of white carbon black into the container, then add 20-35 parts of polyether, start stirring and heat up to 70-80°C, stir for 20-30 minutes, then cool down to 40-55°C, Slowly add 10-20 parts of silicone, stir for 25-35 minutes, then slowly add 45-60 parts of the prepared cross-linked polyacrylic resin blender, and stir for 20-30 minutes to obtain a milky white defoamer emulsion .

[0045] The defoamer of the present invention greatly simplifies the component formula and prepar...

Embodiment 1

[0049] A preparation method of a combined polyether silicone defoamer for fermentation in this embodiment comprises the following steps:

[0050] (1) First prepare the cross-linked polyacrylic acid resin blending agent, dissolve 0.3 parts of alkyl acrylate cross-linked resin in 40 parts of deionized water, stir well and add 0.2 parts of triethanolamine to adjust the cross-linked polyacrylic resin blend The pH of the solution is 8.

[0051] (2) First put 2 parts of white carbon black (hydrophobic fumed silica) into the container, then add 28 parts of ethylene oxide / propylene oxide block polyether, start stirring and heat up to 75°C, stir After 20 minutes, cool down to 40°C, slowly add 16 parts of silicone (ethoxylated silicone oil), stir for 30 minutes, then slowly add 50 parts of cross-linked polyacrylic resin blender that has been prepared, and stir for 20 minutes to obtain Milky white antifoam emulsion.

Embodiment 2

[0070] A preparation method of a combined polyether silicone defoamer for fermentation in this embodiment comprises the following steps:

[0071] (1) First prepare the cross-linked polyacrylic acid resin blending agent, dissolve 0.5 parts of alkyl acrylate cross-linked resin in 50 parts of deionized water, stir well and add 0.1 part of triethanolamine to adjust the cross-linked polyacrylic resin blend The pH of the solution is 7.5.

[0072] (2) First put 1 part of white carbon black (hydrophobic fumed silica) into the container, then add 20 parts of ethylene oxide / propylene oxide block polyether, start stirring and heat up to 80°C, stir After 30 minutes, cool down to 45°C, slowly add 10 parts of silicone (ethoxylated silicone oil), and stir for 25 minutes, then slowly add 60 parts of the prepared cross-linked polyacrylic acid resin blending agent, and stir for 35 minutes to obtain Milky white antifoam emulsion.

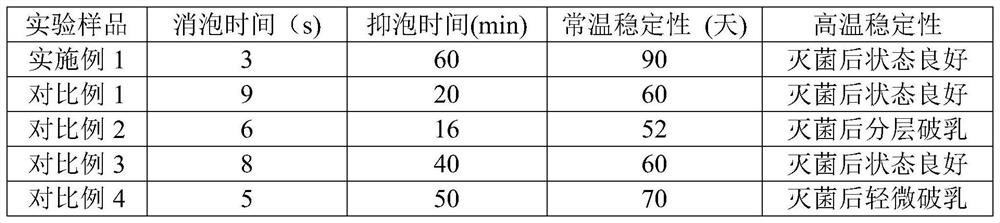

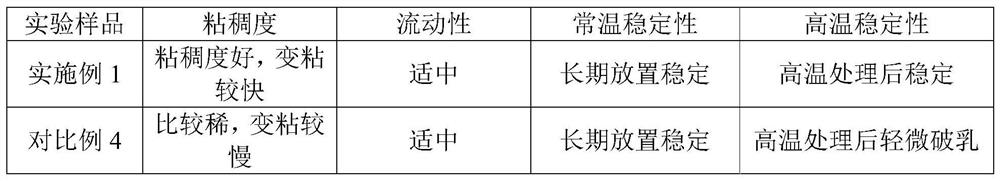

[0073] The stability and the defoaming and anti-foaming effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com