Foam waste collecting device and use method thereof

A waste collection and waste technology, applied in cleaning methods and utensils, chemical instruments and methods, solid waste removal, etc., can solve the problems of increased workload of workers, waste of resources, difficult to take out and store, etc. The effect of time utilization, reduced working time, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

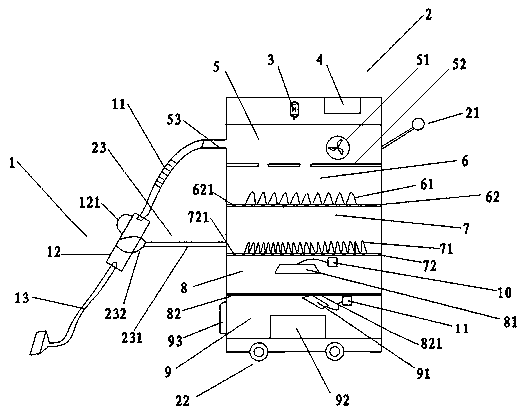

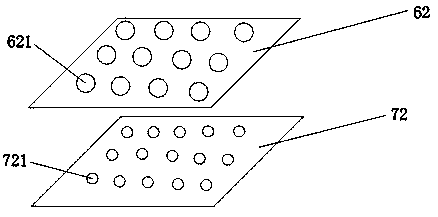

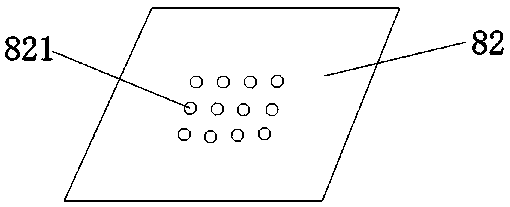

[0024] like Figure 1-3 As shown, this embodiment provides a foam waste collection device, which can automatically and efficiently clean up foam waste and collect foam waste in granules. The foam waste collection device includes: a waste suction assembly 1, a body 2, several Drive motor 3, power supply unit 4, described waste material suction assembly 1 comprises hose 11, plastic hard tube 12, waste material suction head 13, and described fuselage 2 comprises drive layer 5, cutting layer 6, crushing layer 7, hot pressing layer 8. The storage layer 9, the drive 5 is separated from the cutting layer 6 by a baffle plate 52 with a gap, and the cutting layer 6 is separated from the crushing layer 7 by a first screen 62 The crushing layer 7 is separated from the hot-pressed layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com