Technical method for controlling warping deformation of aluminum alloy thin-wall part in 3D printing process

A 3D printing and process method technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve problems such as instability, printing failure, warping and deformation, and improve printing success rate and quality, and improve quality and success rate, and the effect of reducing the cost of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

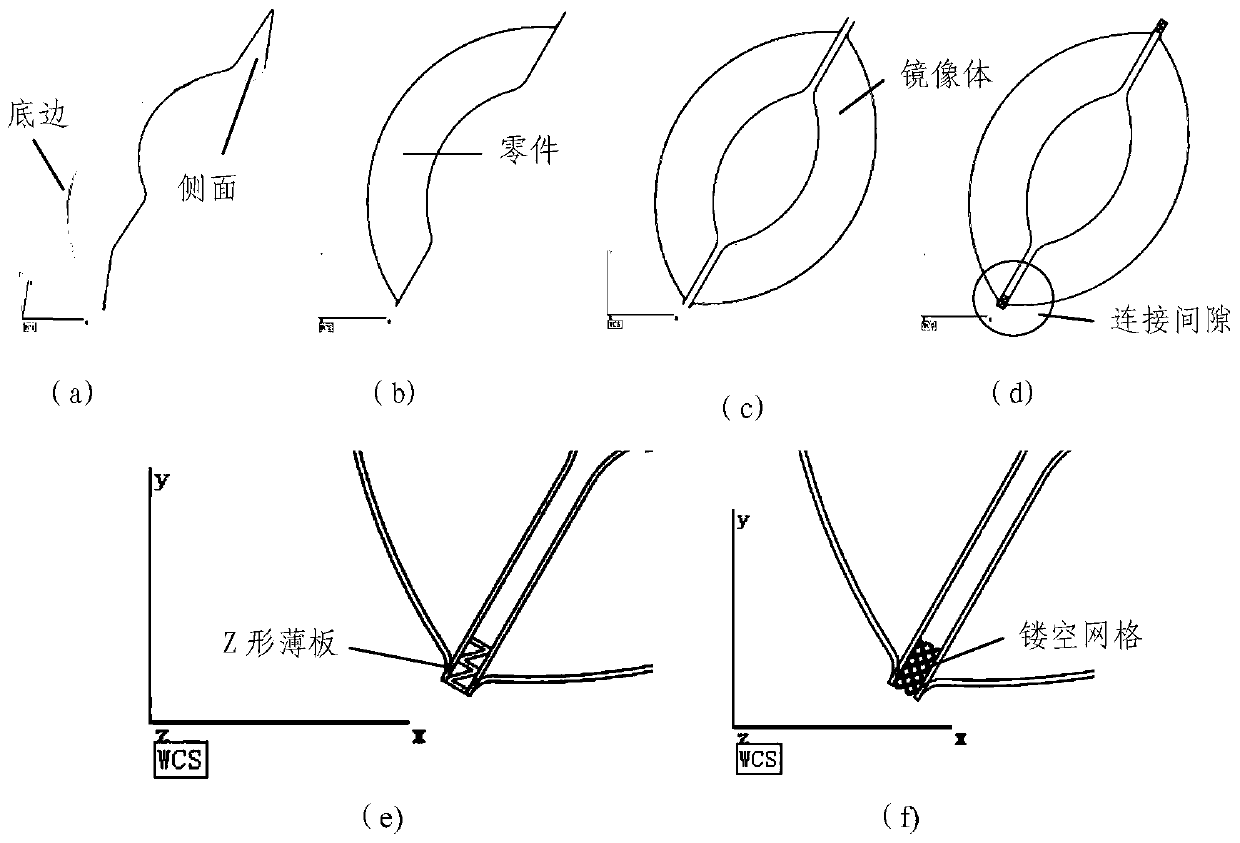

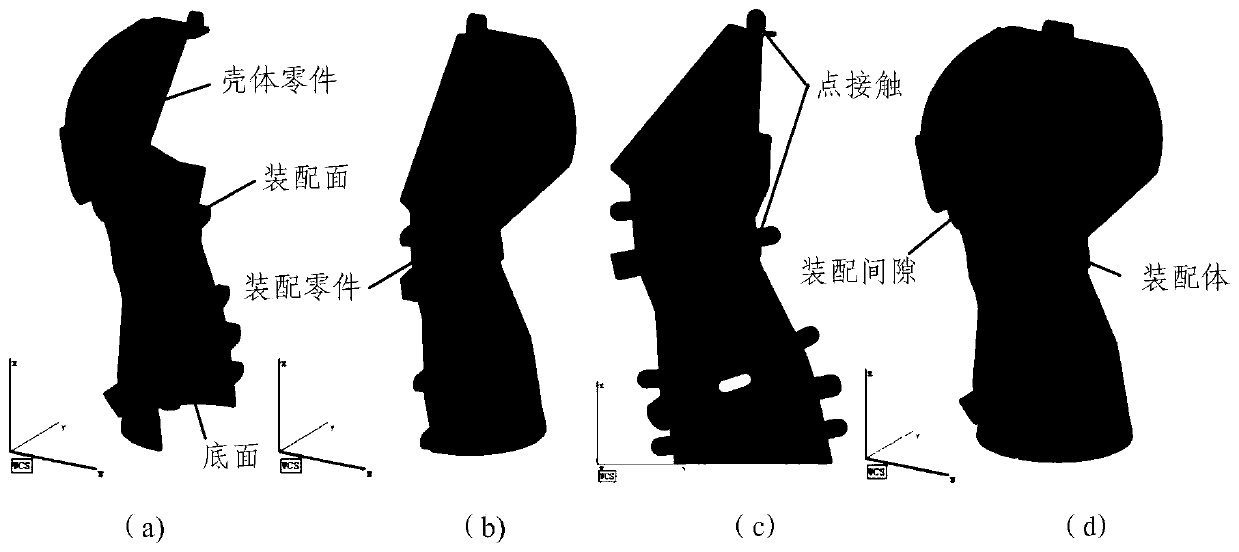

[0015] The invention relates to a process method for controlling warping and deformation of aluminum alloy thin-walled parts during 3D printing, mainly through designing a new type of process support, and using the plane of the forming direction (Z direction) as the mirror surface to generate the mirror image of the part Body, mirror body and part will form a closed structure on the forming surface (XOY surface), the gap between the part and the mirror body is 3-5mm, and the gap is filled with a Z-shaped thin plate (the wall thickness is the same as that of the part) or a hollow grid structure , connect the part with the mirror body, remove the support structure by wire cutting, and get the printed part; for parts with a symmetrical structure, directly rotate one of the parts around the Z axis by 180 degrees, and place the two parts symmetrically with a gap of 3-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com