Combined acid-alkali adjusting zanthoxylum bungeanum maxim seed biocontrol bacterial fertilizer and preparation method thereof

An acid-base adjustment and prickly ash seed technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as inability to adjust fertilizers, and achieve the effects of promoting plant root growth, improving soil physical and chemical properties, and promoting plant growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

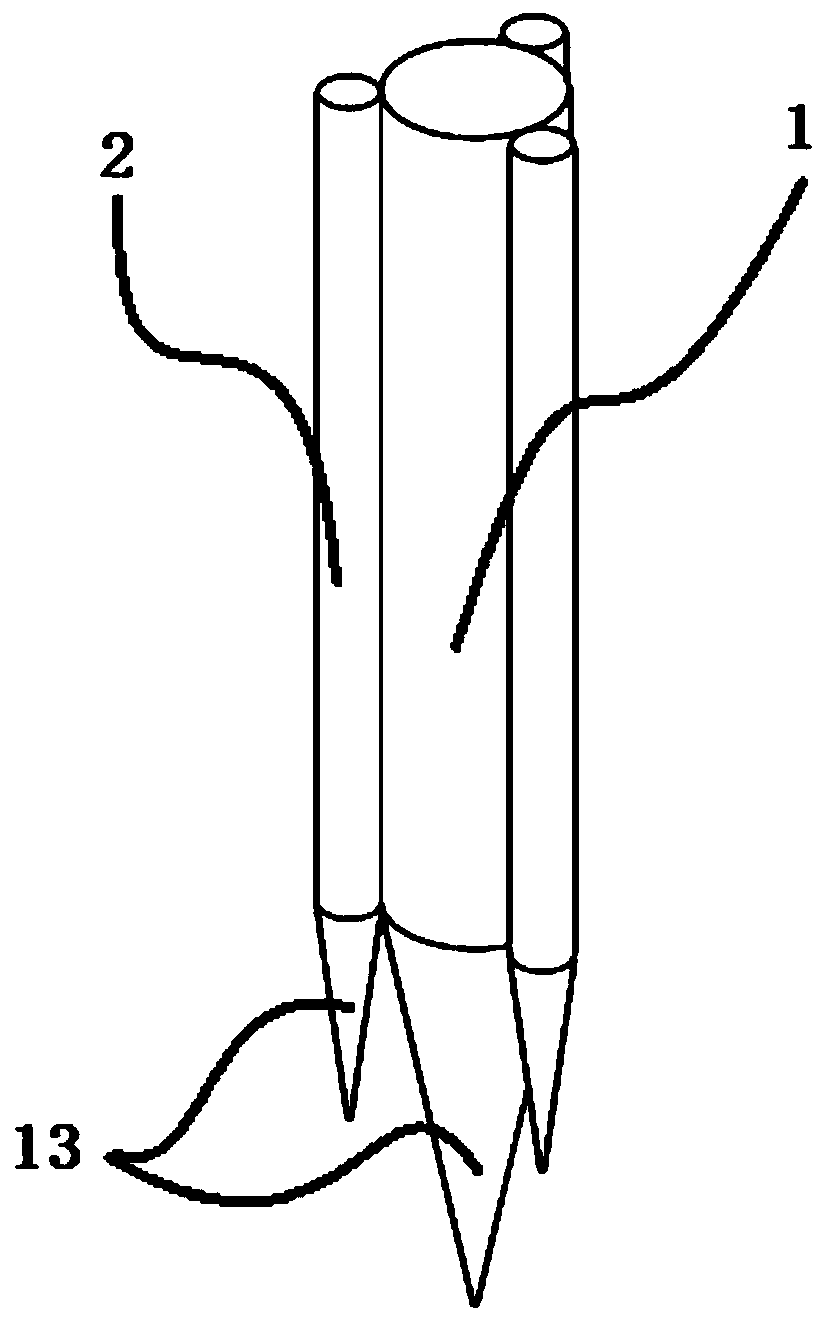

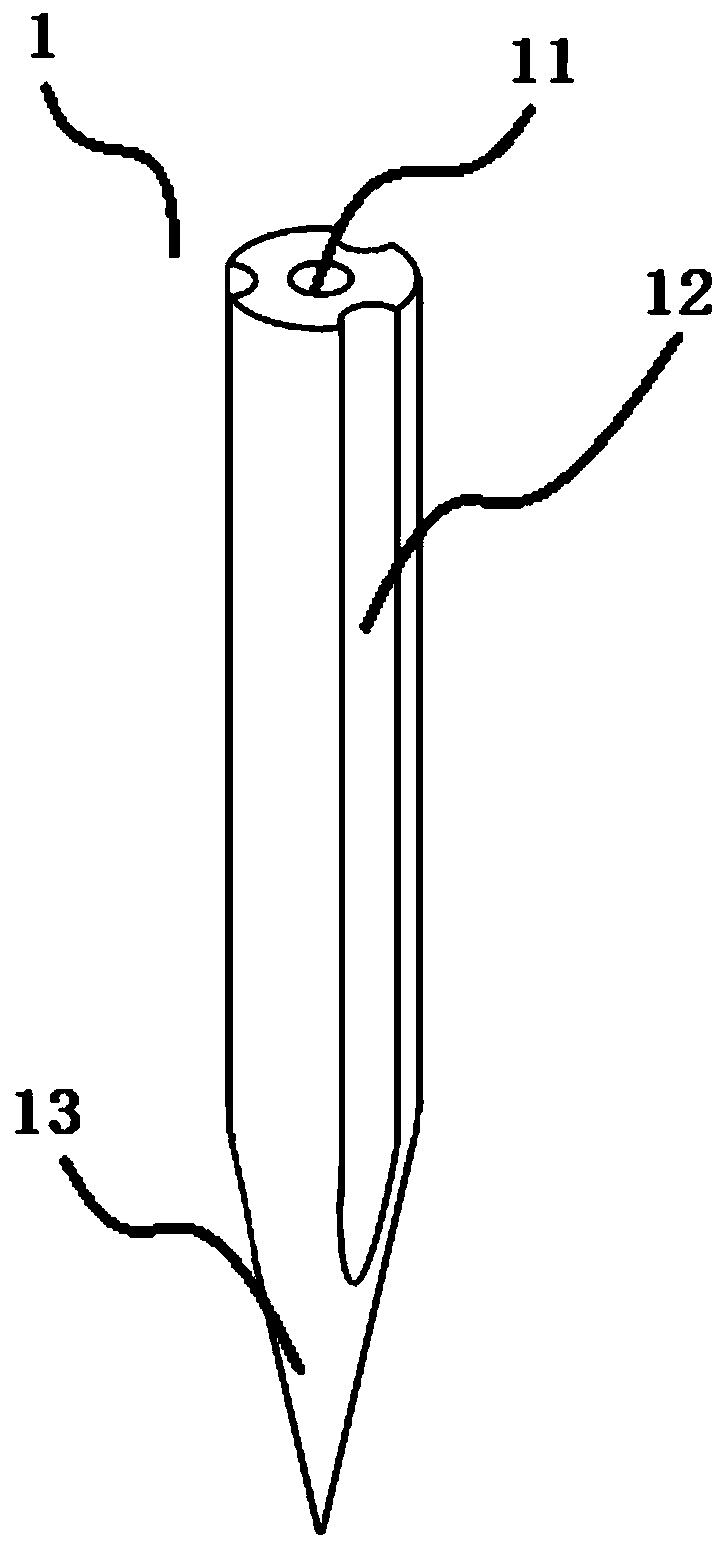

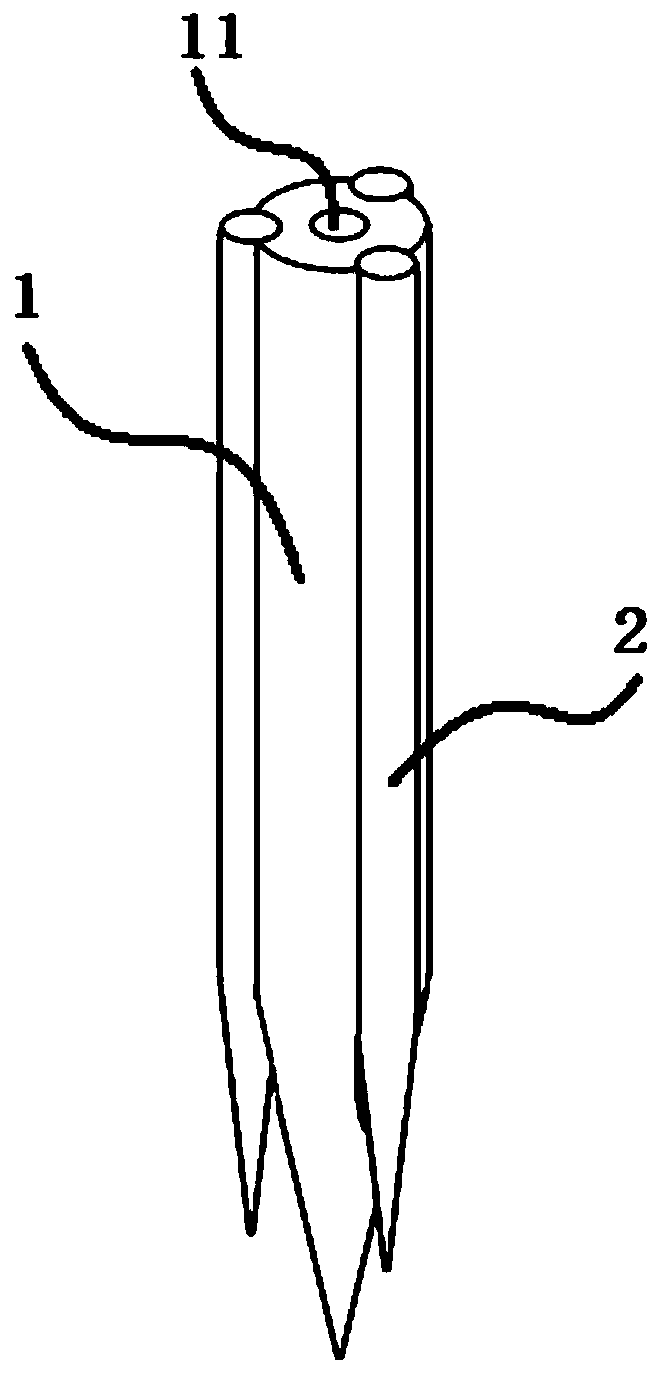

Image

Examples

Embodiment 1

[0045] The preparation of the combined acid-base regulating Zanthoxylum bungeanum biocontrol bacterial fertilizer of the present invention comprises the steps of:

[0046](1) Preparation of raw materials for part A: Take 17 parts by mass of Zanthoxylum bungeanum seeds and 5 parts by mass of cassava, crush them and mix them uniformly, and then add 0.07 parts by mass of Bacillus subtilis bacterial liquid, 33 parts by mass of water, fermented at 28°C for 7 days;

[0047] Among them, the Bacillus subtilis bacterial liquid is preferably Bacillus subtilis Tpb55, which is isolated and preserved by the Tobacco Research Institute of the Chinese Academy of Agricultural Sciences, activated and cultivated with LB (Luria-Bertani) medium, and resuspended to OD=0.5 with sterile water for later use.

[0048] (2) Preparation of raw materials for part B: take rice husks as raw materials and prepare them by anaerobic pyrolysis at 400°C, control the air-dried moisture content (MAD) of biomass cha...

Embodiment 2

[0055] (1) Preparation of raw materials for part A: Take 16 parts by mass of Zanthoxylum bungeanum seeds and 1.7 parts by mass of cassava, grind them and mix them evenly, and then add 0.05 parts by mass of Bacillus subtilis bacterial liquid, 33 parts by mass of water, fermented at 28°C for 7 days;

[0056] (3) Forming part A and part B: put the raw materials of part A and 45 parts by mass of the raw materials of part B into a fertilizer molding machine and press them into rods respectively to obtain part A and part B;

[0057] Other steps are the same.

Embodiment 3

[0059] (1) Preparation of raw materials for part A: Take 20 parts by mass of Zanthoxylum bungeanum seeds and 3.5 parts by mass of cassava, grind them and mix them evenly, and then add 0.08 parts by mass of Bacillus subtilis bacterial liquid, 33 parts by mass of water, fermented at 28°C for 7 days;

[0060] (3) Forming part A and part B: put the raw materials of part A and 25 parts by mass of the raw materials of part B into a fertilizer forming machine and press them into rods respectively to obtain part A and part B;

[0061] Other steps are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com