Preparation method of chitosan hydrogel

A technology of hydrogel and chitosan, which is applied in the field of preparation of chitosan hydrogel, can solve the problems of too high and cytotoxicity, etc., and achieves the effects of simple method, precise control of gelation time, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

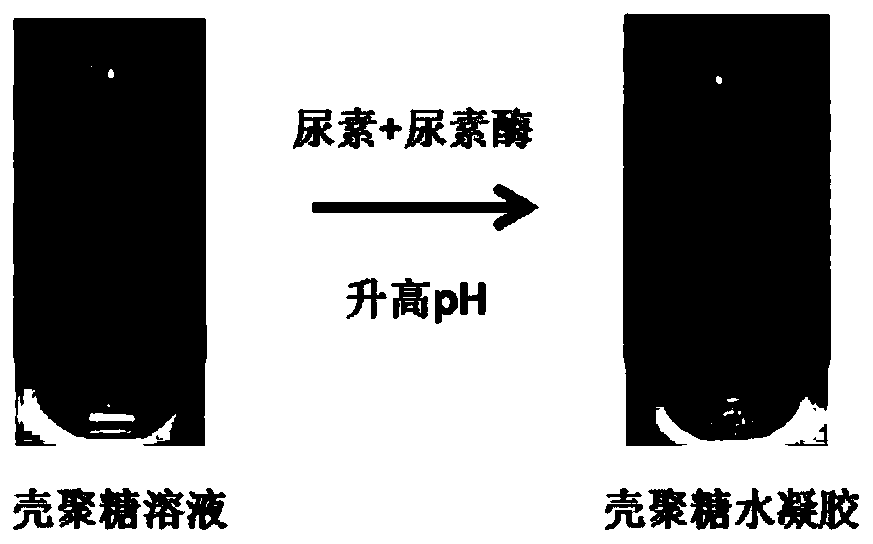

[0027] The invention discloses a preparation method of a chitosan hydrogel. Adding urea and urease into a chitosan solution can uniformly increase the pH value of the chitosan solution to make it gel and obtain the chitosan hydrogel.

[0028] refer to figure 1 , add 1-50mg / L phenol red to the chitosan solution as a pH indicator, before adding urea and urease, the solution is yellow, after adding urea and urease, the solution turns into a gel state and is purple .

Embodiment approach

[0029] The present invention provides an embodiment, comprising the following steps:

[0030] 1. Prepare 0.1-0.2M hydrochloric acid / acetic acid (1-50mg / L phenol red can be added as a pH indicator);

[0031] 2. Dissolve chitosan in acetic acid or hydrochloric acid to prepare a chitosan solution with a concentration of 1-5g / 100ml;

[0032] 3. Dissolving urease in PBS to prepare 5-1000U / ml urease solution;

[0033] 4. Dissolving urea (urea) in deionized water to prepare 8-10M urea solution;

[0034] 5. Mix the chitosan solution and the urease solution evenly, then add the urea solution and mix evenly to prepare chitosan enzymatic physical crosslinking hydrogel.

Embodiment 1

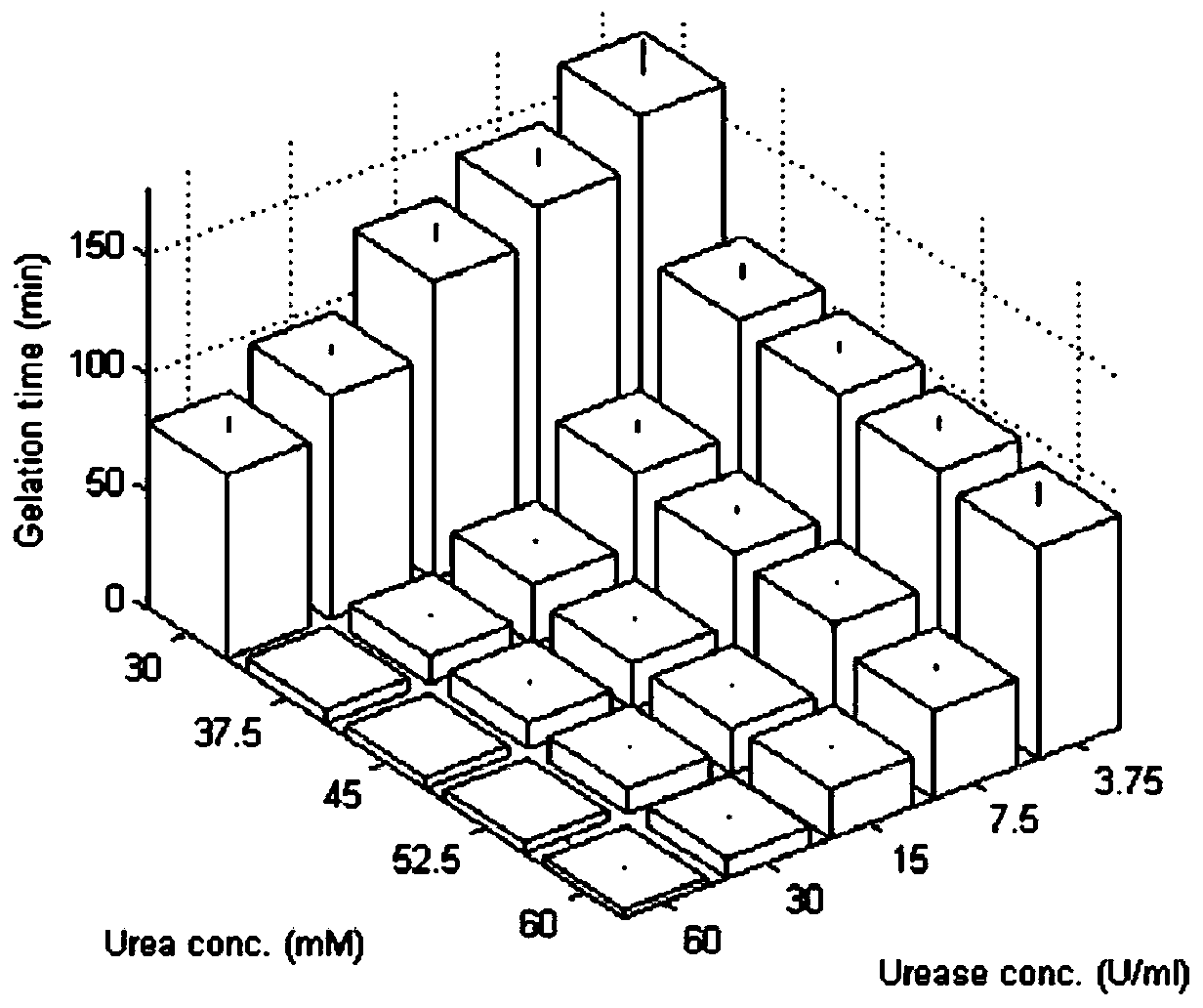

[0036] The present embodiment starts with the chitosan solution whose concentration is 2.5g / 100ml in 1ml, and the addition amount of urease is respectively 3.75, 7.5, 15, 30, 600U / ml through investigation, and the addition amount of urea is respectively 30, 37.5, 45 , 52.5, 60mM, the gelation time of chitosan enzymatically cross-linked hydrogel, the results are as follows figure 2 As shown, the test tube inversion method was used to detect the gelation time of chitosan enzymatically cross-linked hydrogel. Put the prepared solution in the centrifuge tube in a constant temperature metal bath or water bath, and use a stopwatch to time the gel time. The gel time is the time between the sol flowing in the centrifuge tube and the centrifuge tube not flowing after being inverted.

[0037] From figure 2 It can be seen that within a certain range, the gelation time of chitosan enzymatically physically crosslinked hydrogel can be precisely regulated by adjusting the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com