A kind of preparation method of xpe foaming agent

A technology of foaming agent and co-crosslinking agent, which is applied in the field of preparation of XPE foaming agent, can solve the problems of insufficient smooth and delicate product surface, narrow foamable temperature range, and low operability and elasticity, and improve the workplace. environment, improving melt fluidity, preventing gas escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of XPE foaming agent, comprising the following steps:

[0057] S1, add 100 parts by weight of azodicarbonamide (AC foaming agent), 1 part by weight of zinc stearate, and 1 to 5 parts by weight of foaming activator into a high-speed mixer for 2 minutes, to obtain the first a mixture; then use a jet mill to grind the first mixture to a median particle size of 3 to 15 microns;

[0058] S2, 100 parts by weight of auxiliary foaming agent and 1 part of zinc stearate are added in the high mixer and stirred for 2 minutes to obtain the second mixture; then the second mixture is ground to a median particle size of 3~3 15 micron powder;

[0059] S3, adding 40 parts by weight of fumed silica into the low-speed mixer, then adding 60 parts by weight of the auxiliary crosslinking agent to the low-speed mixer in batches, and waiting for the liquid auxiliary crosslinking agent to be oxidized by the gas phase method After the silicon is absorbed, start the low-spee...

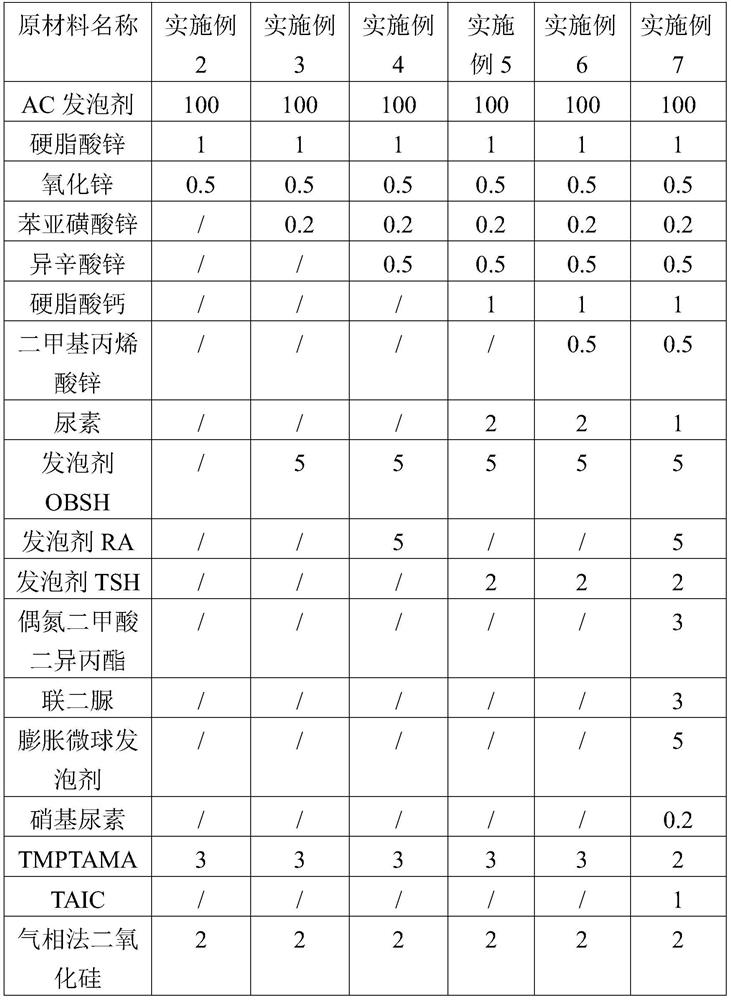

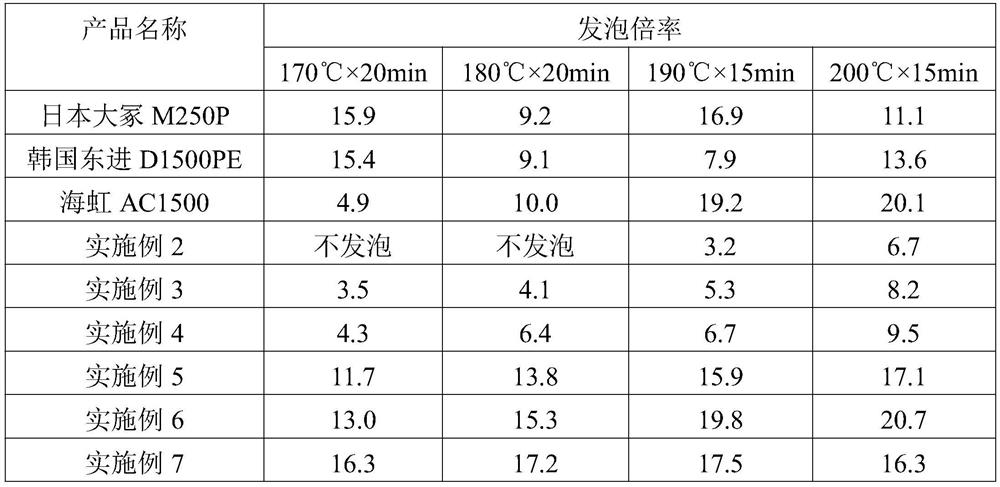

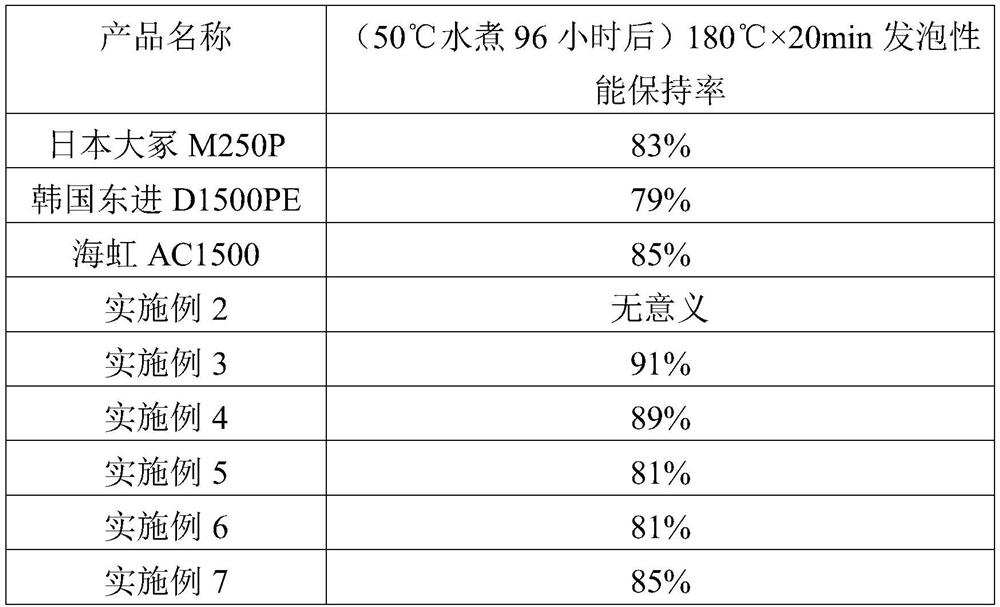

Embodiment 2 to 7

[0073] All adopt the preparation method of following a kind of XPE foaming agent, comprise the following steps:

[0074] S1, add 100 parts by weight of azodicarbonamide (AC foaming agent), 1 part by weight of zinc stearate, and 1 to 5 parts by weight of foaming activator into a high-speed mixer for 2 minutes, to obtain the first a mixture; then use a jet mill to grind the first mixture to a median particle size of 3 to 15 microns;

[0075] S2, 100 parts by weight of auxiliary foaming agent and 1 part of zinc stearate are added to the high mixer and stirred for 2 minutes to obtain the second mixture; then the second mixture is ground to a median particle size of 3~3 15 micron powder;

[0076] S3, adding 40 parts by weight of fumed silica into the low-speed mixer, then adding 60 parts by weight of the auxiliary crosslinking agent to the low-speed mixer in batches, and waiting for the liquid auxiliary crosslinking agent to be oxidized by the gas phase method After the silicon i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com