Powder coating material and applications thereof

A powder coating and base powder technology, applied in the field of materials, can solve the problems of unfavorable powder coating application, high energy consumption of powder coating, poor weather resistance, etc., and achieve the effects of ensuring weather resistance, improving electrification performance, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

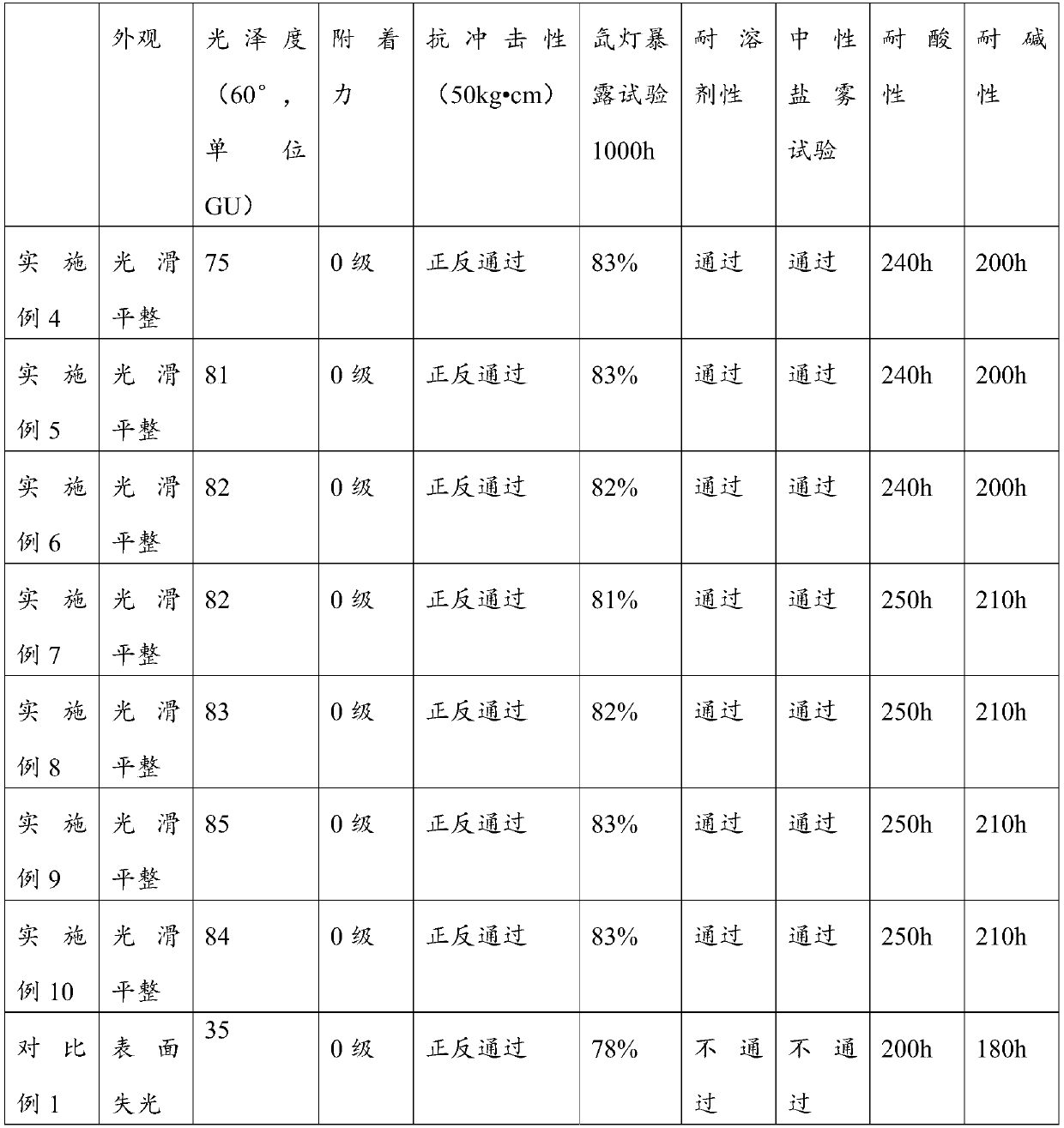

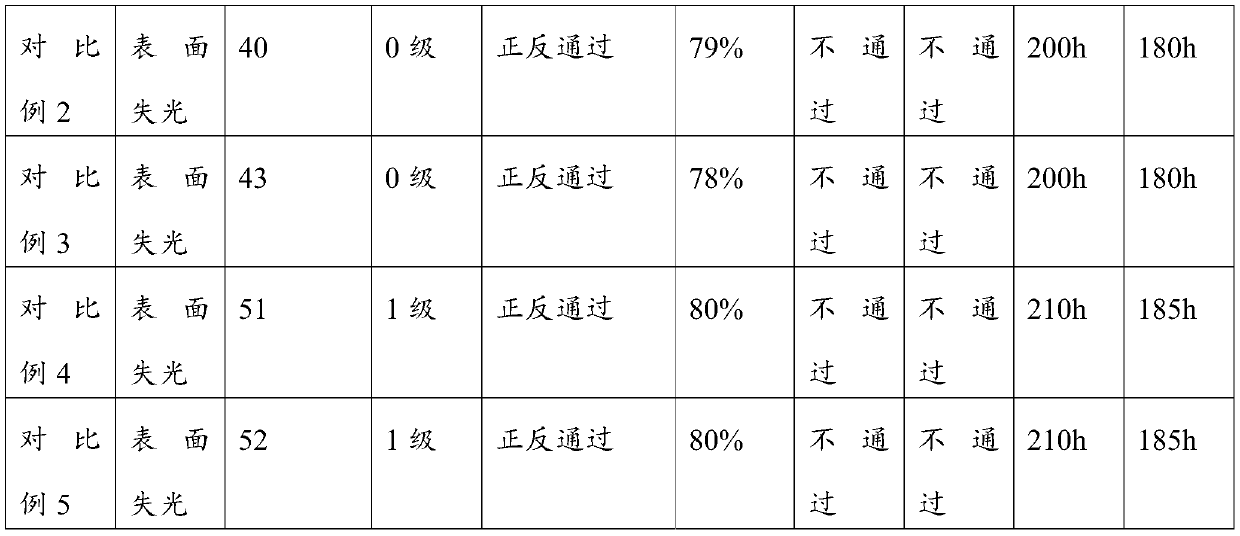

Examples

Embodiment 1

[0067] A leveling agent is prepared through the following steps:

[0068] Mix methyl ethyl ketone and initiator dibenzoyl peroxide, heat to 85°C, then add acrylic acid and polyethylene terephthalate to react, the reaction temperature is 85°C, and the reaction time is 4 hours. Leveling agent.

[0069] The mass ratio of butanone, acrylic acid and polyethylene terephthalate is 100:50:30, and the mass of initiator dibenzoyl peroxide is 12% of butanone.

Embodiment 2

[0071] A leveling agent is prepared through the following steps:

[0072] Mix pentanone and initiator benzoyl peroxide tert-butyl peroxide, heat to 80°C, add crotonic acid and polyethylene glycol, and react. The reaction temperature is 80°C, and the reaction time is 4.5 hours to obtain a stream leveling agent.

[0073] The mass ratio of pentanone, crotonic acid and polyethylene glycol is 100:30:60, and the mass of initiator benzoyl peroxide tert-butyl peroxide is 14% of the mass of pentanone.

Embodiment 3

[0075] Compared with Example 1, polyvinyl alcohol is used to replace polyethylene terephthalate in Example 3, and the rest of the preparation process is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com