Handcart switch cabinet

A technology of switch cabinets and handcarts, which is applied in the direction of pull-out switch cabinets, switchgears, instruments, etc., which can solve problems such as the combination of dynamic and static contacts, high installation costs, and overheating of internal contacts, so as to avoid debugging accuracy Low, improve operational reliability, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

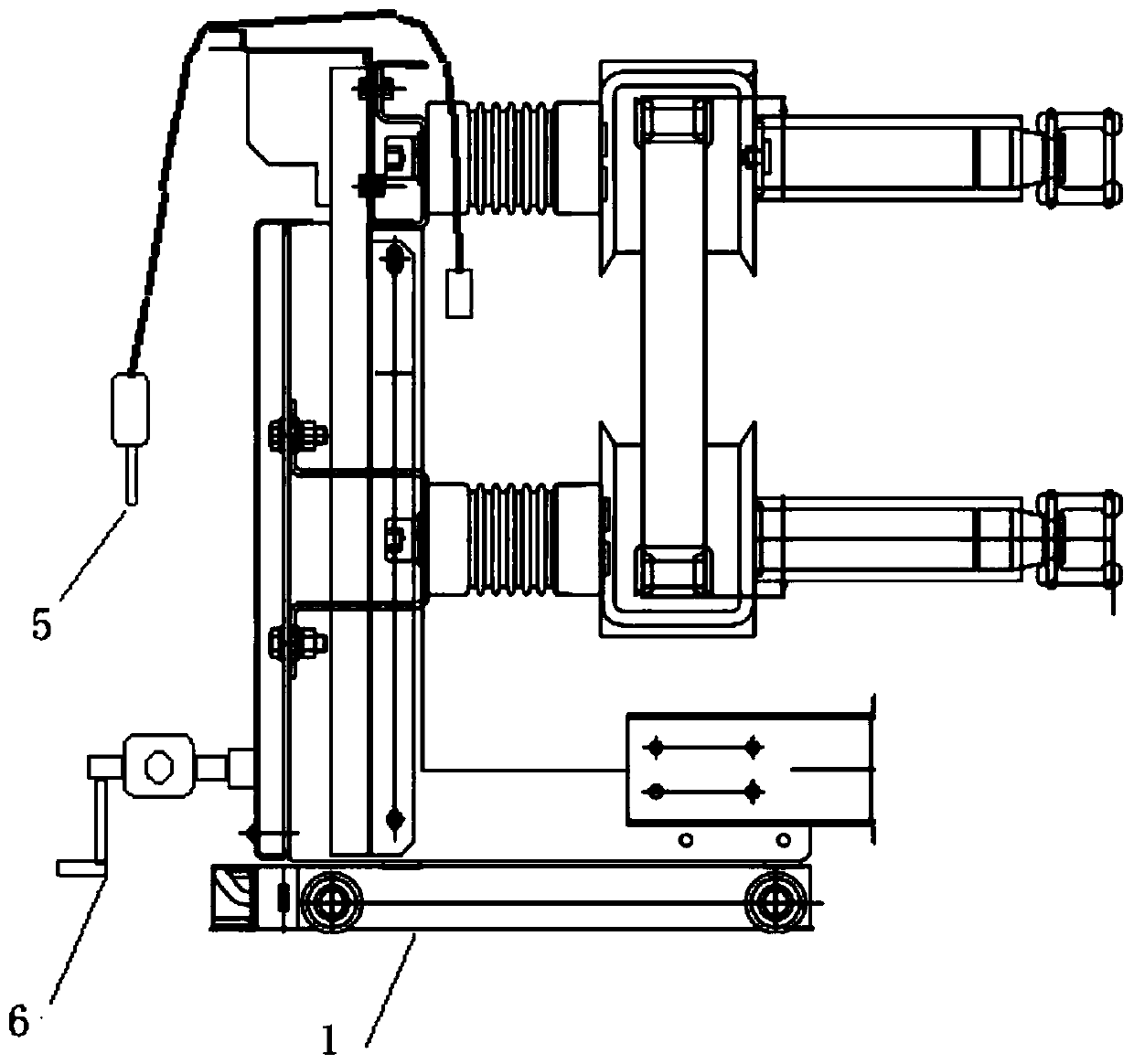

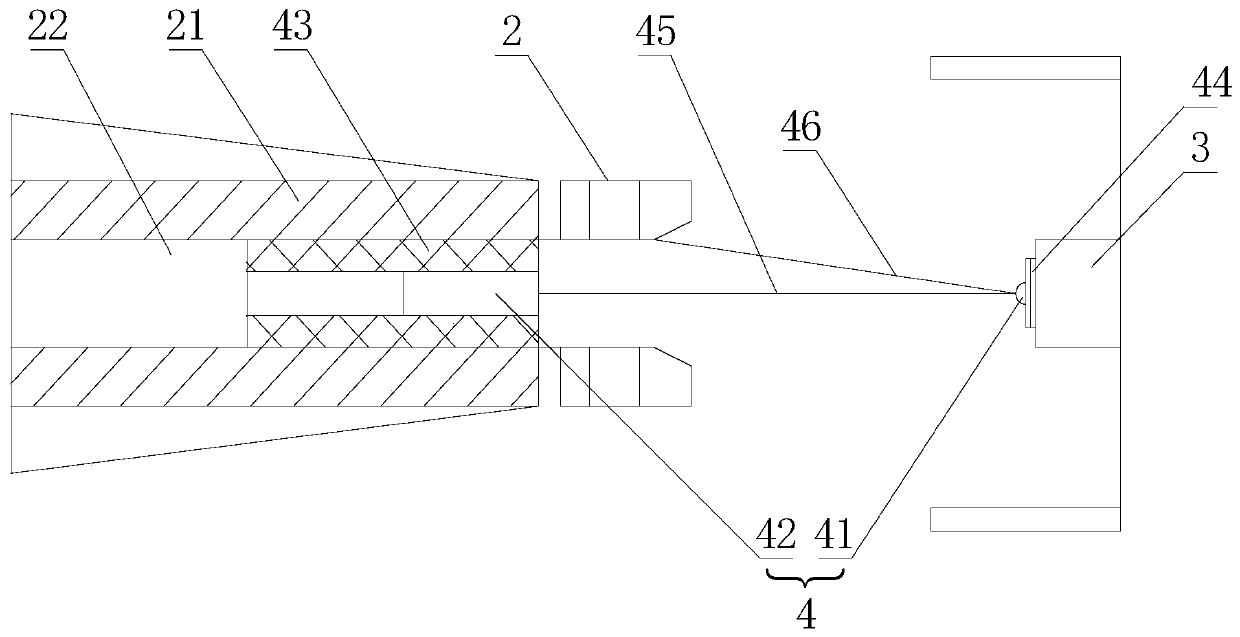

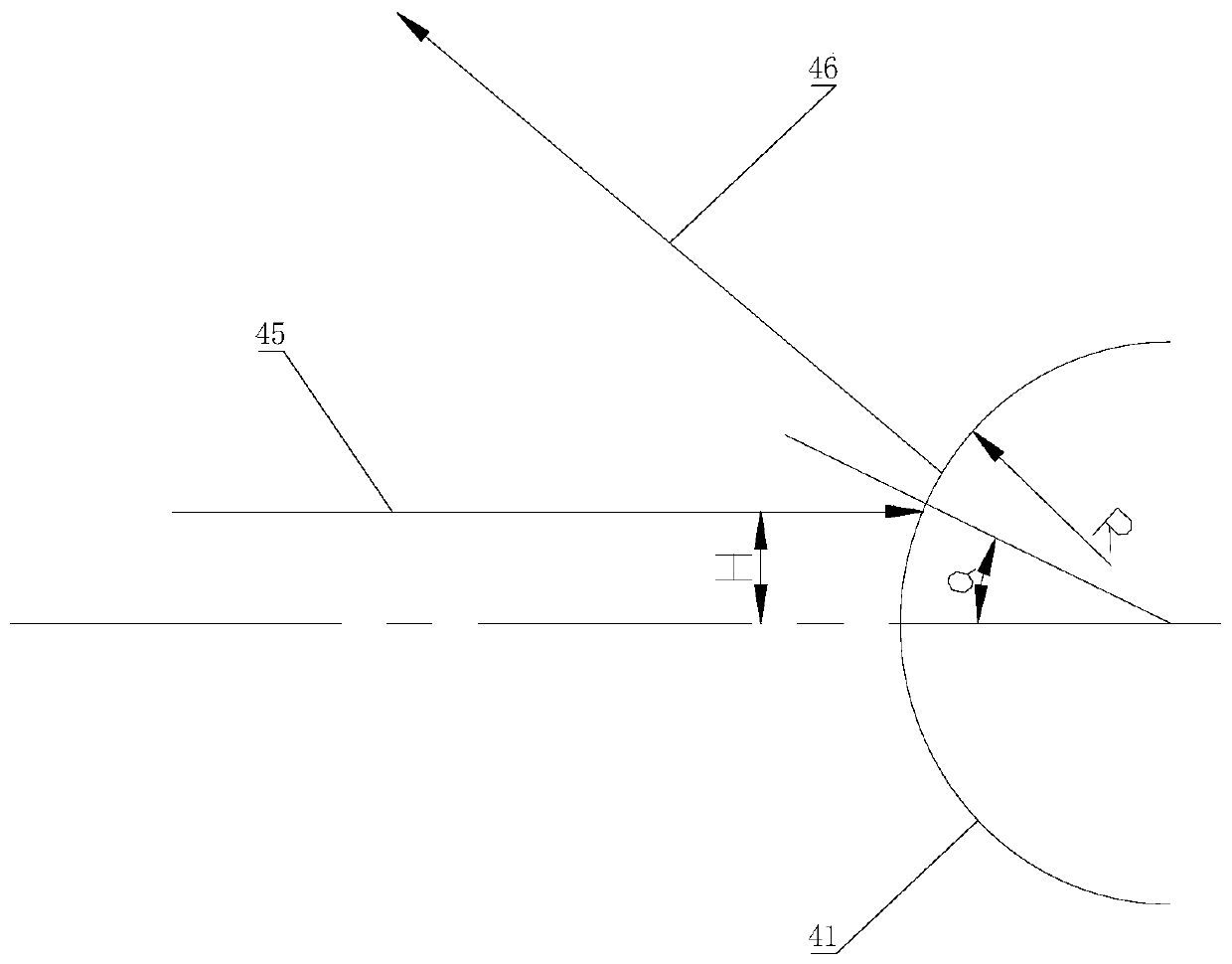

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the handcart switch cabinet includes a body 1, the body 1 includes a moving contact 2 and a static contact 3, the moving contact 2 includes a conductive rod 21, and also includes a detection component 4 and an electronic endoscope camera 5 , considering the large internal space of the handcart switch, the position of the endoscope lens is not easy to fix, so the electronic endoscope camera 5 is a 360-degree panoramic camera, which can be controlled by an external rocker to facilitate the expansion of the internal observation range. The detection component 4 includes Spherical reflector 41 and green laser 42, the spherical reflector 41 and green laser 42 are six, respectively installed in the three-phase six moving contacts 2 and static contacts 3 inside the body 1, the The green laser 42 is arranged on the conductive rod 21, and the horizontal axis of the green laser 42 coincides with the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com