Special tobacco fertilizer for improving water retention capacity of tobacco planting soil

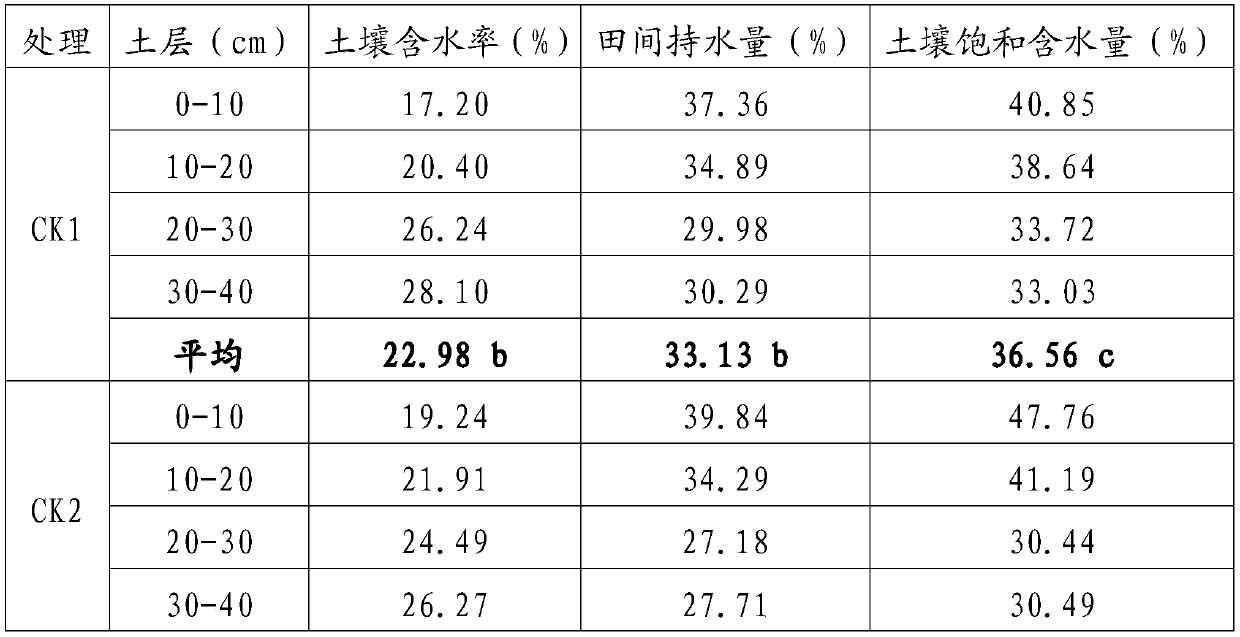

A special fertilizer and soil technology, applied in the directions of alkaline orthophosphate fertilizers, fertilizer mixtures, ammonium orthophosphate fertilizers, etc., can solve problems such as the limitation of topographic conditions for tobacco leaf production, affecting the growth and development of tobacco plants, and drought and water shortage in tobacco fields. To achieve the effect of improving the adsorption capacity, improving the ability of water storage and moisture retention, and improving the water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

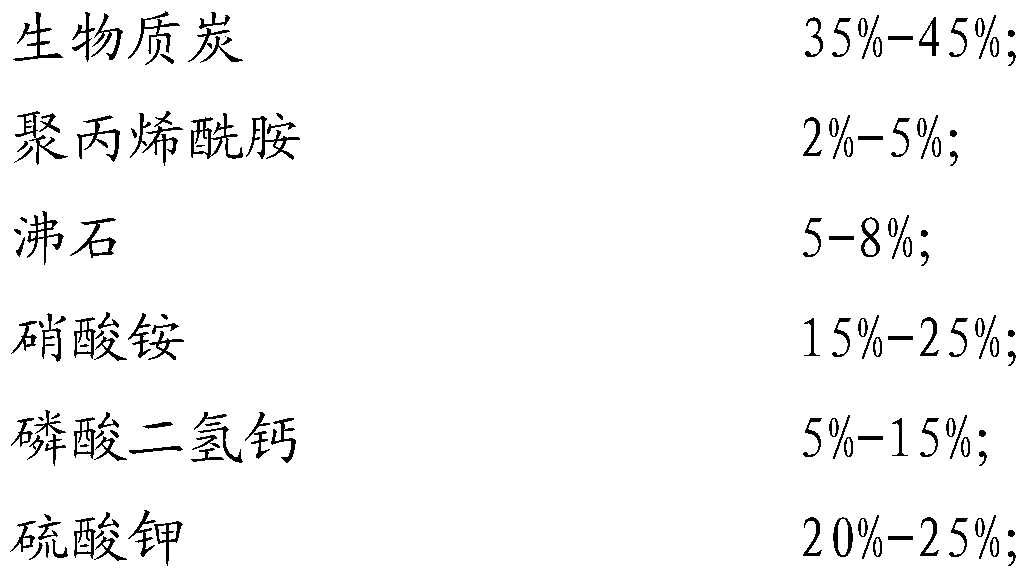

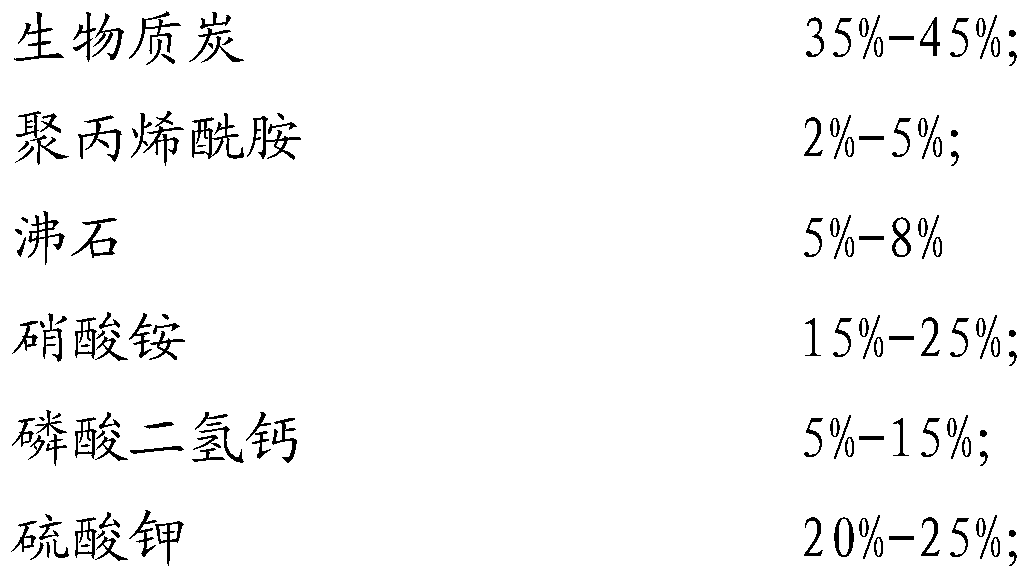

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of blasting biochar, comprising the following steps:

[0027] (1) Mechanically pulverize the tobacco stalk into 2-3cm;

[0028] (2) Place the pulverized tobacco rod in a steam blaster, heat it to 2.0-2.5MPa with 120-260°C saturated steam, and keep it for 5-10min;

[0029] (3) Rapid decompression to atmospheric pressure within 1 / 100s to achieve instantaneous blasting;

[0030] (4) After drying at 45-60°C, crush and sieve to prepare explosive biochar.

preparation example 1

[0032] The preparation method of explosive biochar comprises the following steps:

[0033] (1) mechanically pulverize the tobacco stalk into 2cm;

[0034] (2) Place the pulverized tobacco rod in a steam blaster, heat it to 2.0MPa with 120°C saturated steam, and keep it for 10min;

[0035] (3) Rapid decompression to atmospheric pressure within 1 / 100s to achieve instantaneous blasting;

[0036] (4) After drying at 45°C, crush and sieve to prepare explosive biochar P1.

[0037] The prepared explosive biochar P1 has a pH of 7.75, a total carbon content of 45.30%, a total nitrogen content of 2.35%, and a specific surface area of 1.47m 2 / g.

preparation example 2

[0039] The preparation method of explosive biochar comprises the following steps:

[0040] (1) mechanically pulverize the tobacco stalk into 3cm;

[0041] (2) Place the pulverized tobacco rod in a steam blaster, heat it to 2.5MPa with 260°C saturated steam, and keep it for 5min;

[0042] (3) Rapid decompression to atmospheric pressure within 1 / 100s to achieve instantaneous blasting;

[0043] (4) After drying at 60°C, crush and sieve to prepare explosive biochar P2.

[0044] The prepared explosive biochar P2 has a pH of 8.05, a total carbon content of 45.73%, a total nitrogen content of 2.50%, and a specific surface area of 1.64m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com