Anti-icing and de-icing method for total temperature sensor

A temperature sensor and anti-icing technology, used in deicing devices, instruments, thermometers, etc., can solve the problems of large error, inaccurate total temperature measurement, long response time, etc., to achieve fast temperature measurement, improve accuracy, and response. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

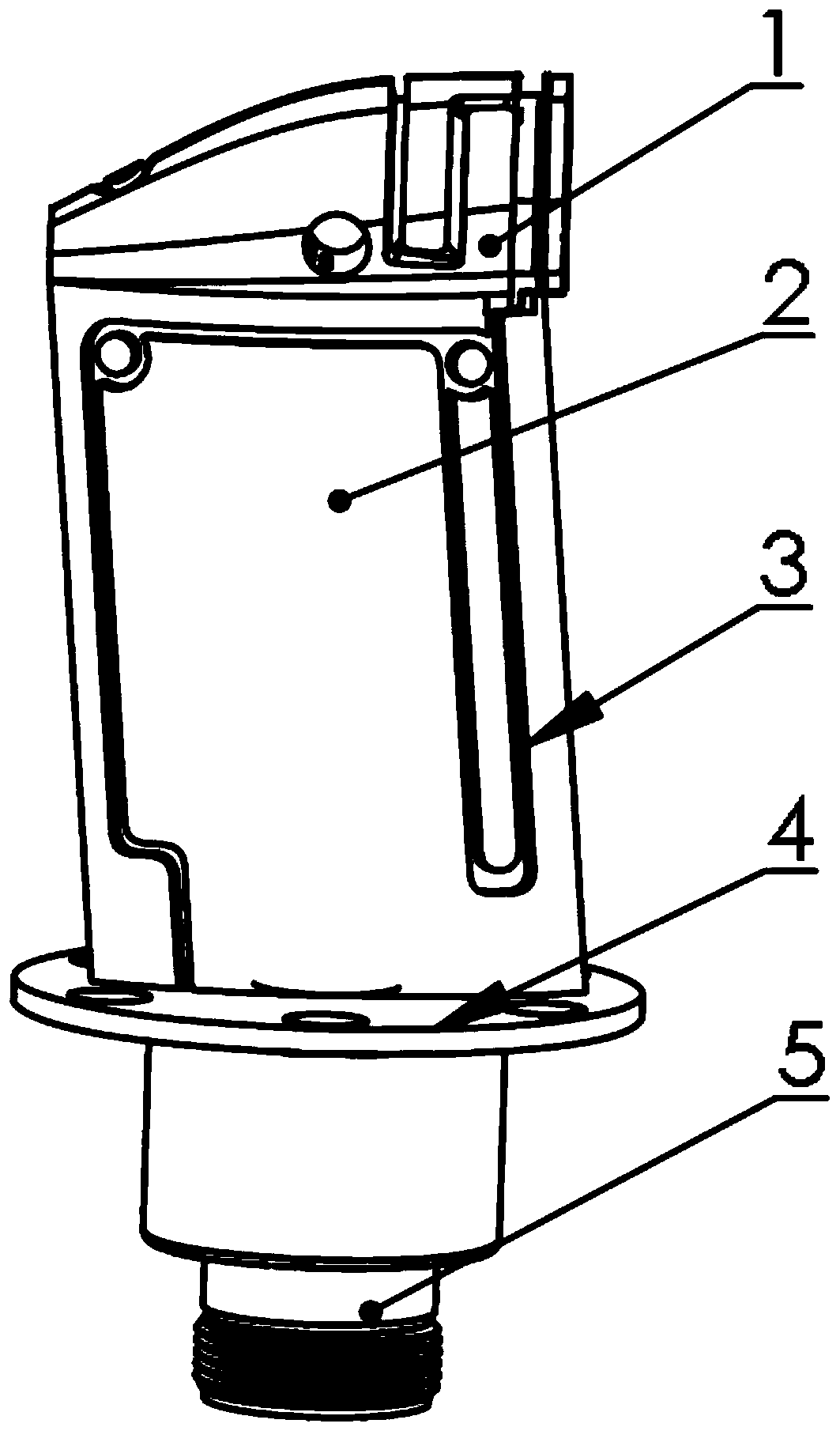

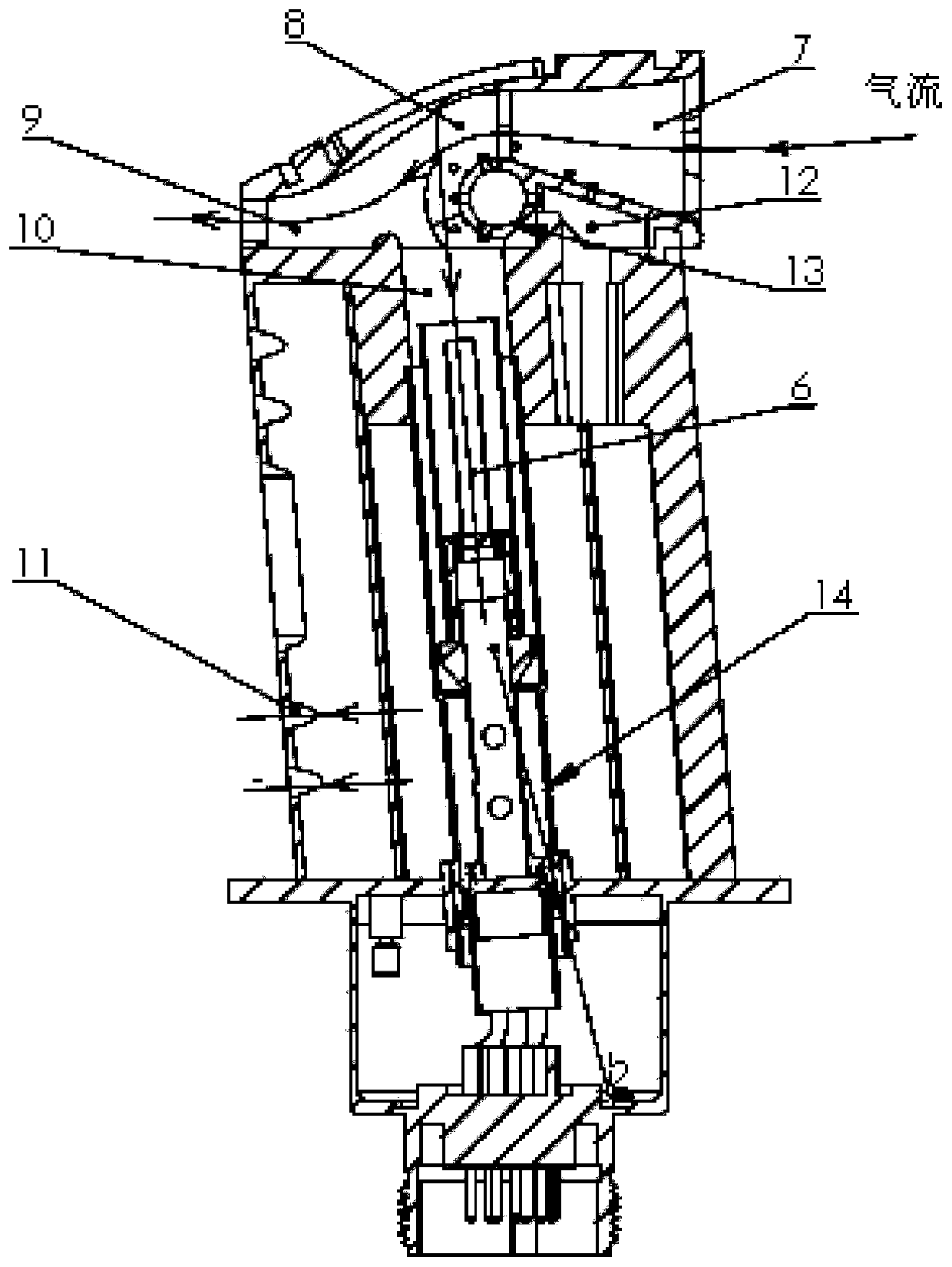

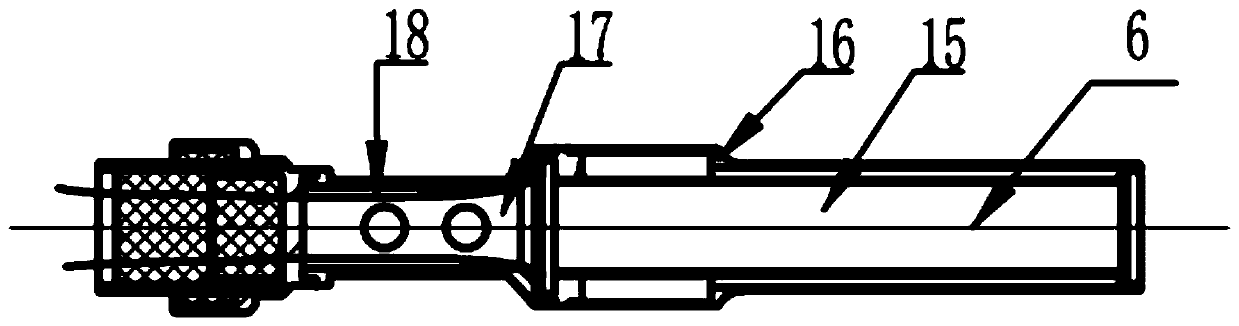

[0020] refer to figure 1 , figure 2 . According to the present invention, the top of the T-shaped pillar stagnation cover 2 connected by the flange plate 4 forms a T-shaped tube cylindrical air duct 1 that first diffuses and then shrinks. The opening of the gas port expands in the form of a trumpet and shrinks backward. Under the lower wall of the shrinkage hole at the junction of the throat 8 of the T-shaped pipe, the circular arc transition is tangent to the pin shaft guide side hole as the fulcrum, and it bends and shrinks radially downward. Gradually diffuse downwards to the root of the T-shaped tube, and then extend and contract from the bottom wall of the root of the T-shaped tube along its diffusion section and pass through the exhaust port 9 at the tail end to form a Laval cylindrical stagnation chamber; stagnant in the T-shaped pillar The bottom end of the cover 2 is fixedly connected to the flange 4, the connector 5 is connected to the bottom of the flange, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com