Gas type super-fine dry powder automatic fire extinguishing system

An automatic fire extinguishing system and ultra-fine dry powder technology, applied in fire rescue, fire alarms that rely on radiation, and measuring devices, can solve problems such as difficult maintenance, disasters, and large protection space, and achieve continuous injection pressure. Stable, stable physical and chemical properties, little effect of ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments. The present invention includes but is not limited to the following embodiments.

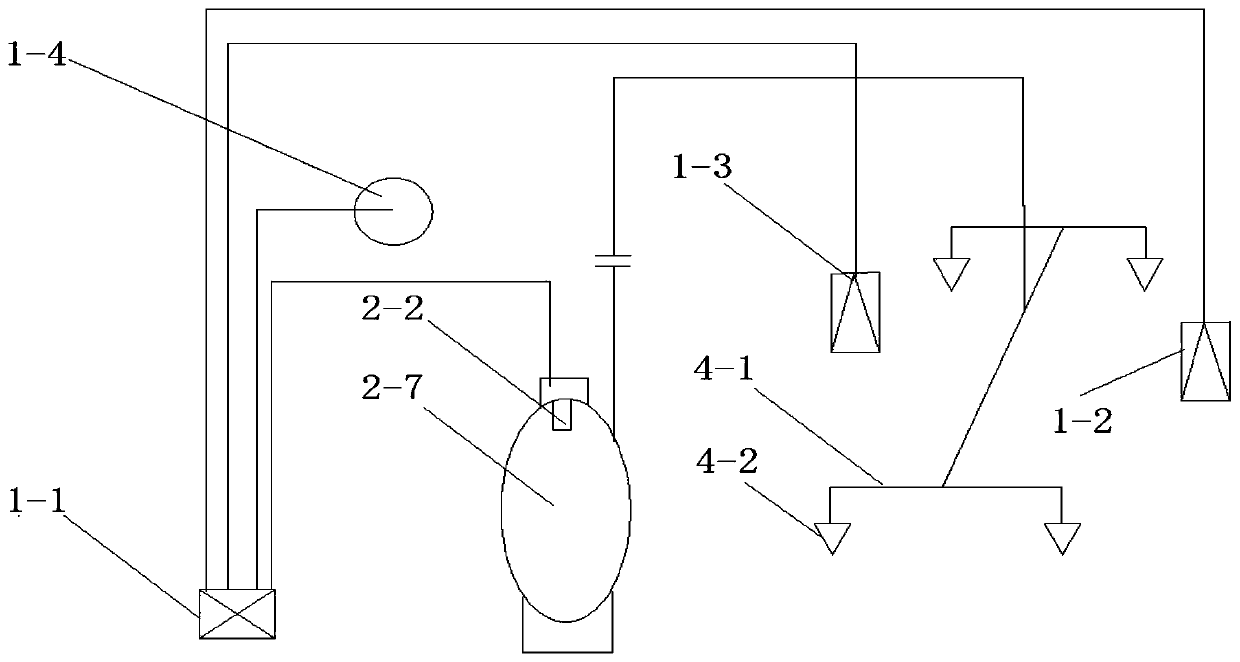

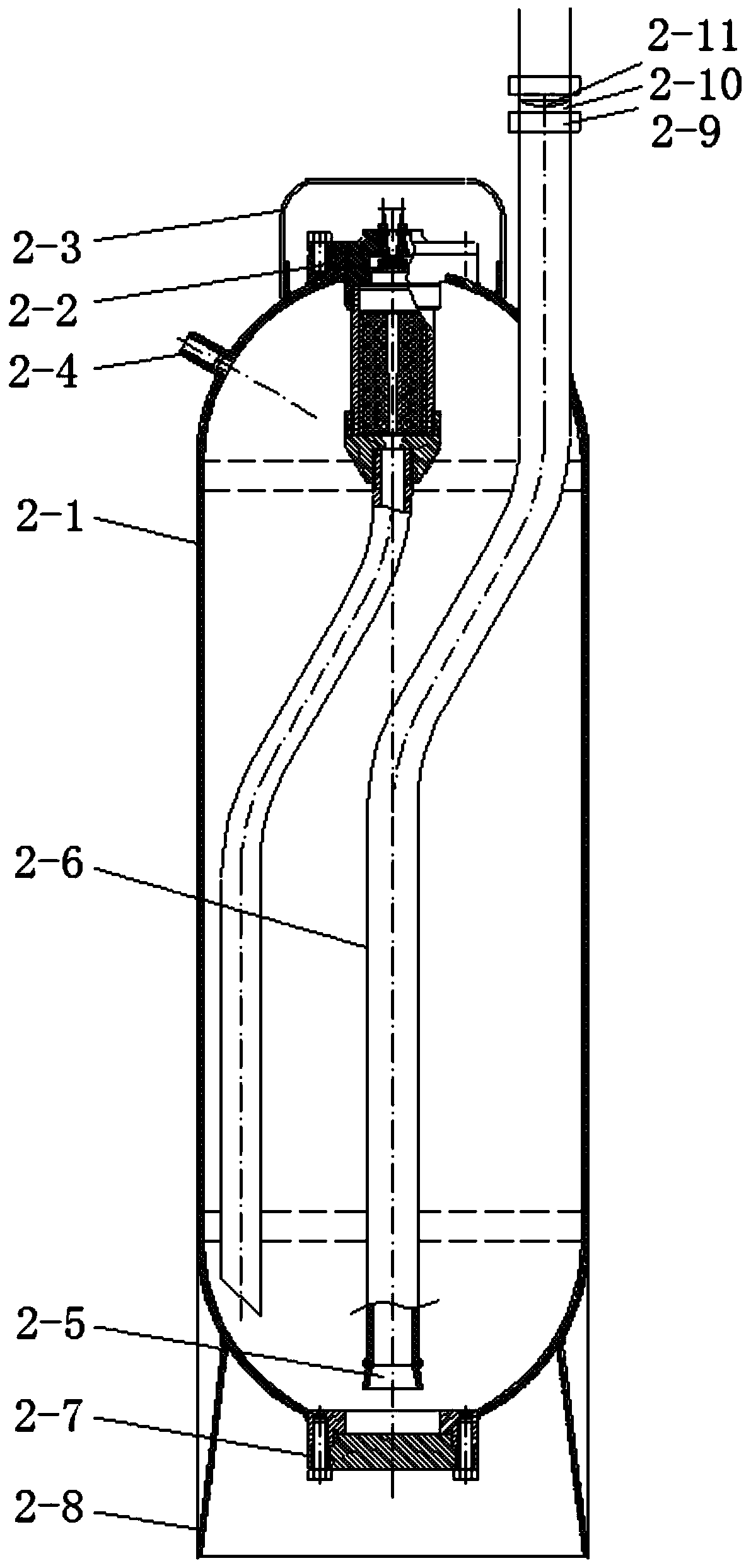

[0029] The invention consists of two parts: a gas-type superfine dry powder automatic fire extinguishing equipment and a fire induction alarm system. The fire induction alarm system belongs to a conventional fire detection system with strong technical versatility and is not the core content of the invention. Among them, the gas-type ultra-fine dry powder automatic fire extinguishing equipment uses the gas generated by the combustion of insensitive gas generating agents to drive the ultra-fine dry powder along the pipeline to the fire source. The gas-fired ultrafine dry powder automatic fire extinguishing equipment includes a gas generator, a fire extinguishing agent, a dry powder tank, a pressure gauge, a rupture disc, a holder, a pipeline and a nozzle.

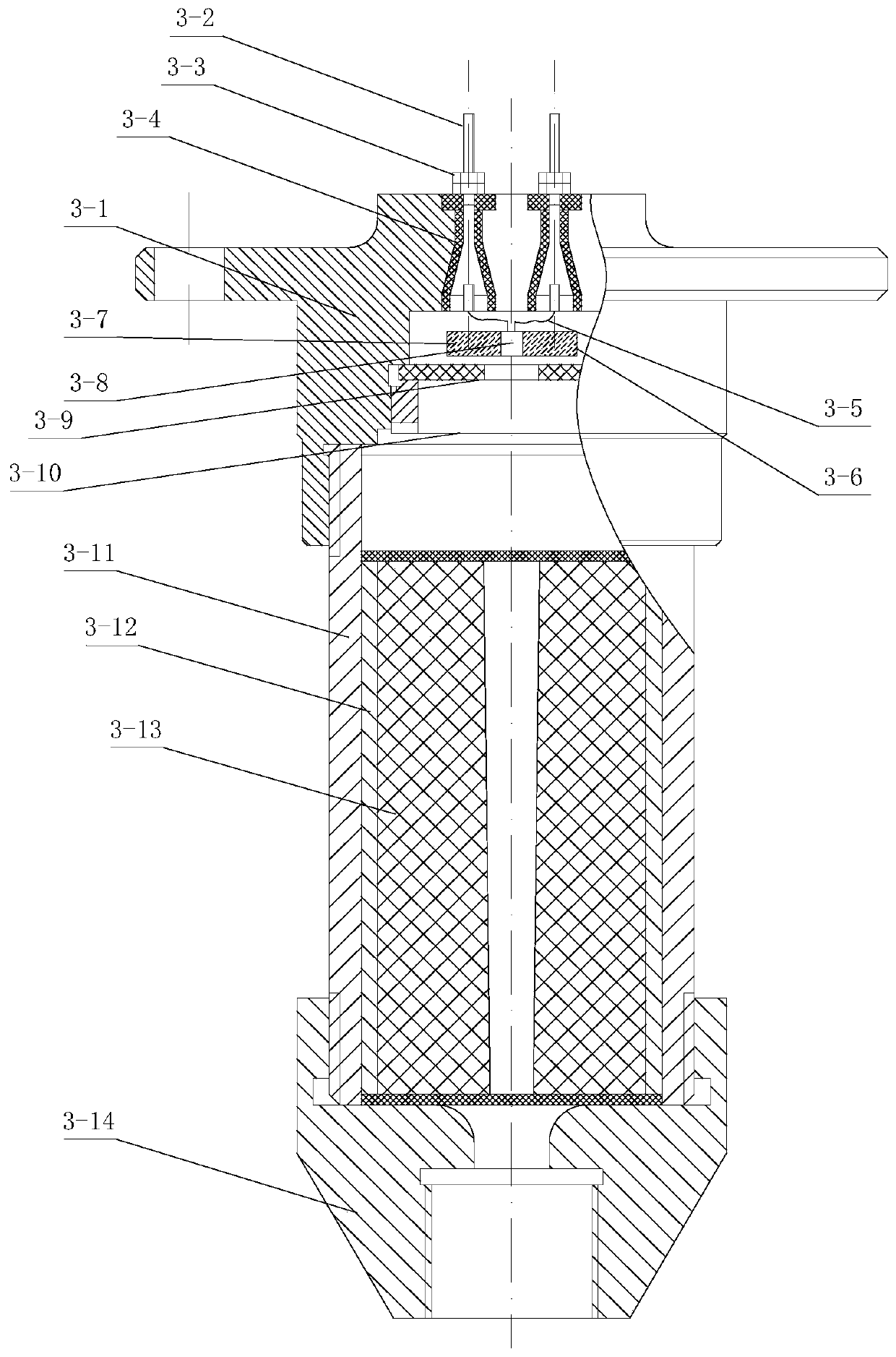

[0030] The gas generator includes a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com