Mo2C catalytic material and preparation method and application thereof

A technology for catalytic materials and composite materials, applied in the field of Mo2C catalytic materials and their preparation, can solve the problems of less surface active sites and less than ideal catalytic activity, and achieve the effects of environmental friendliness, excellent catalytic activity, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

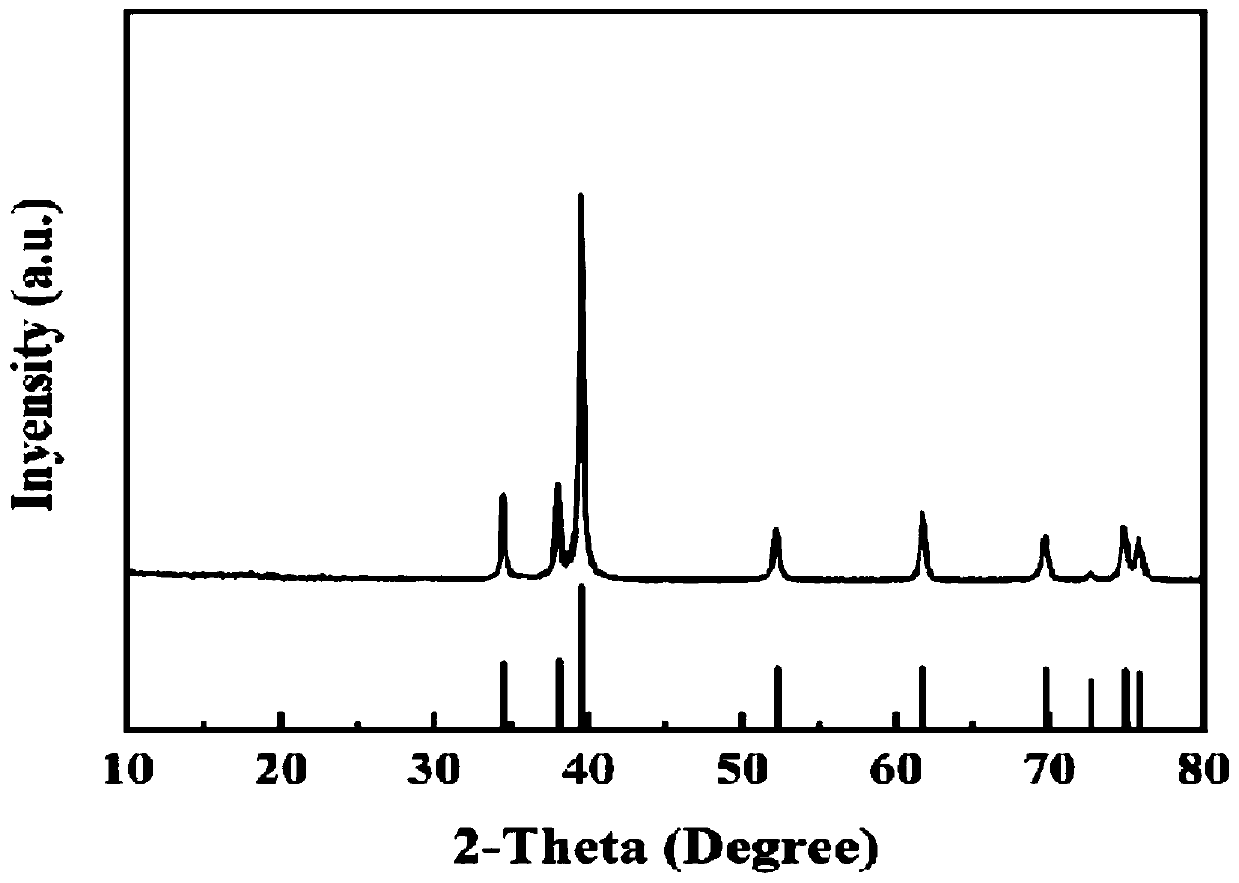

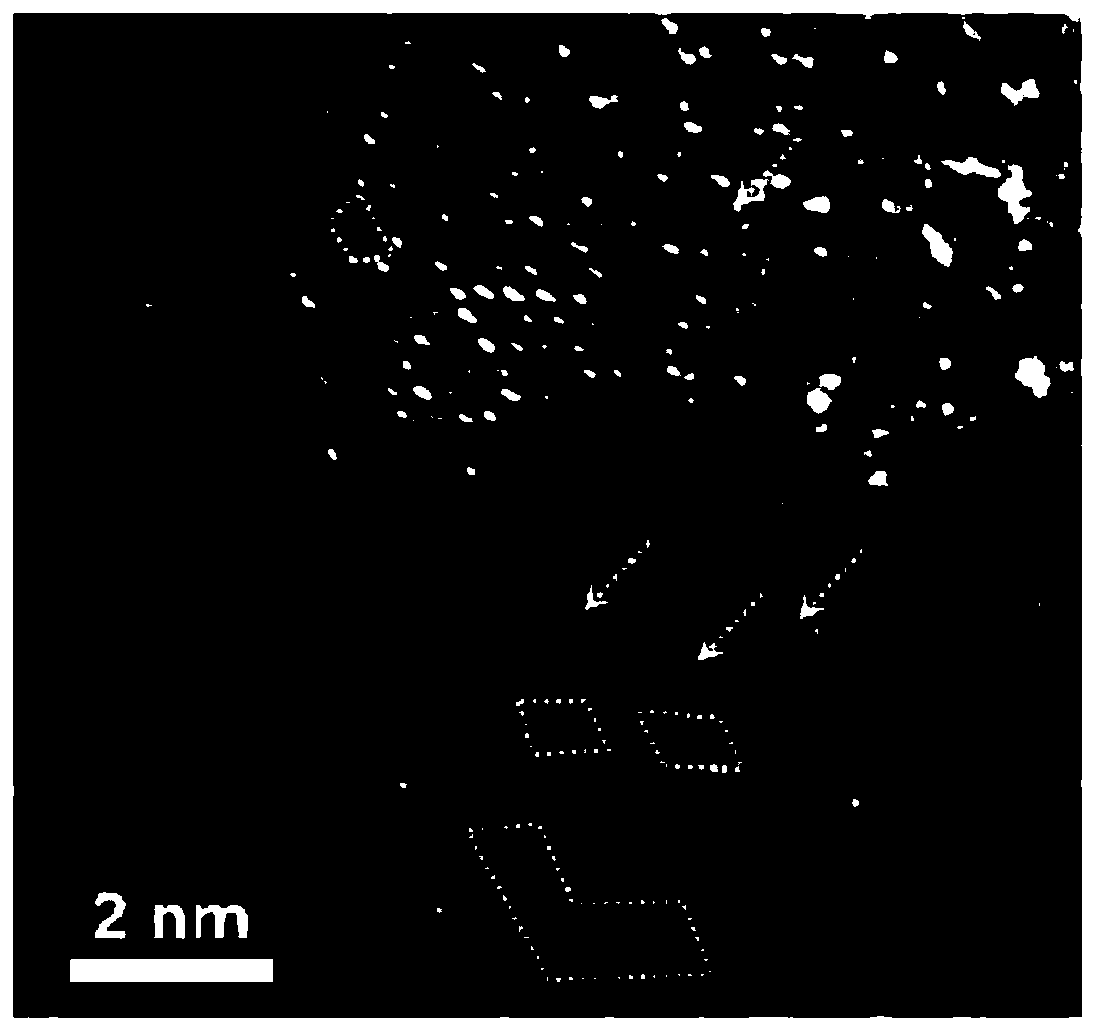

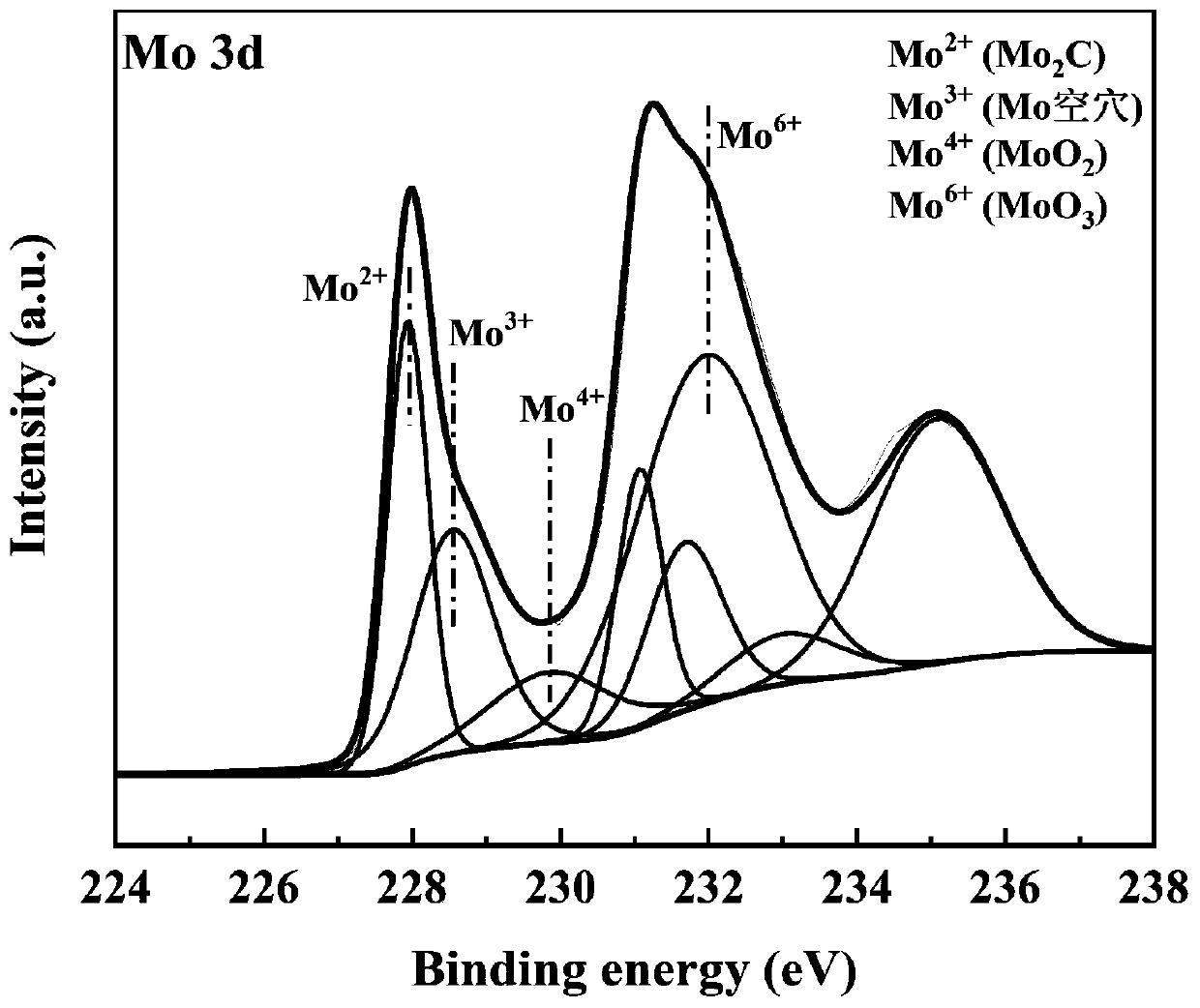

[0040] This example is Mo 2 Preparation of C catalytic materials

[0041] (1) Weigh respectively 0.0652g of molybdenum acetylacetonate and 0.0582g of cobalt nitrate hexahydrate (Co:(Co+Mo)=50% (molar ratio)) into a 50mL polytetrafluoro liner, and simultaneously add 30mL isopropanol and 6 mL glycerin. At room temperature (25° C.) with a rotational speed of 500 rad / min, magnetic stirring was performed for 3 h until the solid was completely dissolved. Finally, seal the polytetrafluoroethylene liner into the reaction kettle body, put it into a 180°C drying oven and heat it for 12 hours. After the kettle was naturally cooled to room temperature, the brown suspension was transferred to a 50 mL centrifuge tube, and centrifuged at 8000 rad / min for 5 min. After the centrifugation is completed, pour off the supernatant and wash with 40mL absolute ethanol for 3 times. The obtained sample was placed in a vacuum drying oven and dried in vacuum at 60° C. for 12 hours to obtain a precurs...

Embodiment 2

[0048] This example is Mo 2 Preparation of C catalytic materials

[0049] (1) Weigh respectively 0.0652g of molybdenum acetylacetonate and 0.00647g of cobalt nitrate hexahydrate (Co:(Co+Mo)=10% (molar ratio)) into a 50mL polytetrafluoro liner, and simultaneously add 30mL isopropanol and 6 mL glycerin. At room temperature (25° C.) with a rotational speed of 500 rad / min, magnetic stirring was performed for 3 h until the solid was completely dissolved. Finally, seal the polytetrafluoroethylene liner into the reaction kettle body, put it in a 220°C drying oven and heat it for 10 hours. After the kettle was naturally cooled to room temperature, the brown suspension was transferred to a 50 mL centrifuge tube, and centrifuged at 8000 rad / min for 5 min. After the centrifugation is completed, pour off the supernatant and wash with 40mL absolute ethanol for 3 times. The obtained sample was placed in a vacuum oven and dried in vacuum at 60° C. for 12 h.

[0050] (2) The above-mentio...

Embodiment 3

[0054] This example is Mo 2 Preparation of C catalytic materials

[0055] (1) Weigh 0.0652g of molybdenum acetylacetonate and 0.232g of cobalt nitrate hexahydrate (Co:(Co+Mo)=80% (molar ratio)) into 50mL polytetrafluoro liner, and add 30mL isopropanol and 6 mL glycerol. At room temperature (25° C.) with a rotational speed of 500 rad / min, magnetic stirring was performed for 3 h until the solid was completely dissolved. Finally, seal the polytetrafluoroethylene liner into the reaction kettle body, put it into a 180°C drying oven and heat it for 12 hours. After the kettle was naturally cooled to room temperature, the brown suspension was transferred to a 50 mL centrifuge tube, and centrifuged at 8000 rad / min for 5 min. After the centrifugation is completed, pour off the supernatant and wash with 40mL absolute ethanol for 3 times. The obtained sample was placed in a vacuum oven and dried in vacuum at 60° C. for 2 h.

[0056] (2) The above-mentioned sample was charged into a q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com