Dislocation equalization joint eliminating method and system for large-breadth DLP type 3D printing machine

A 3D printer and elimination system technology, applied in the field of 3D printing, can solve the problems of high molding size cost, affecting the overall quality of the model, etc., to achieve the effect of eliminating seams, good scalability, and improving the quality of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

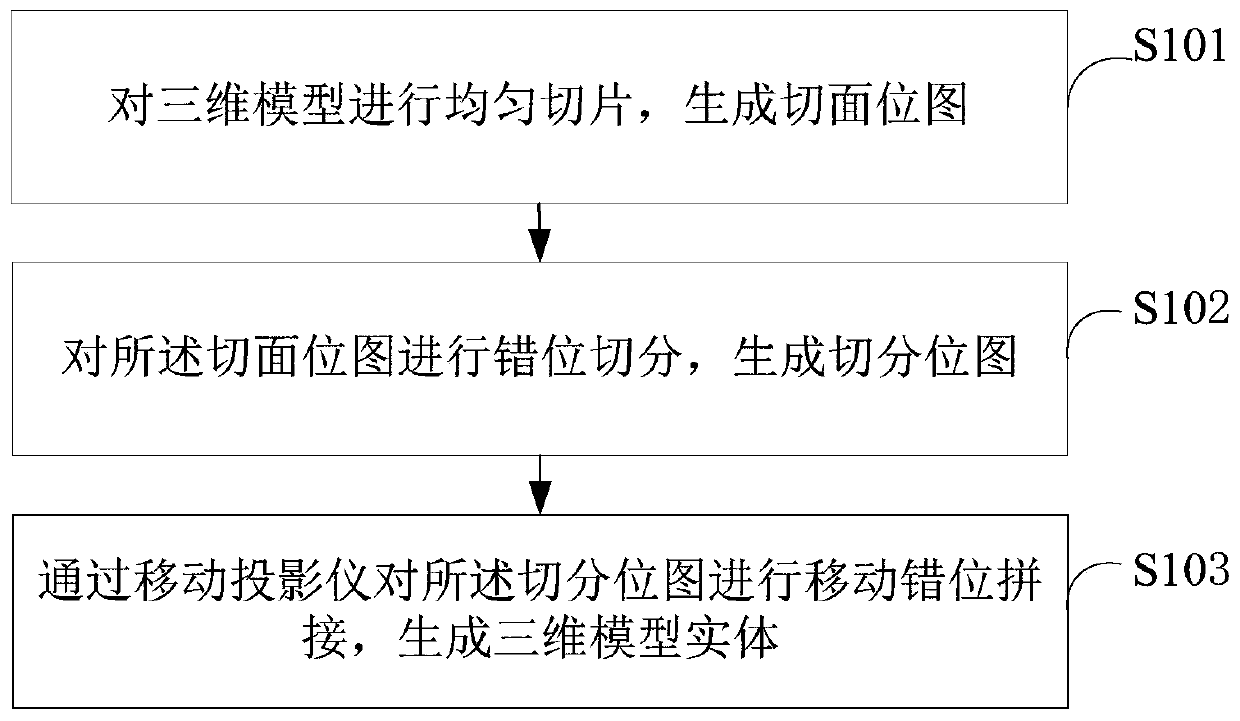

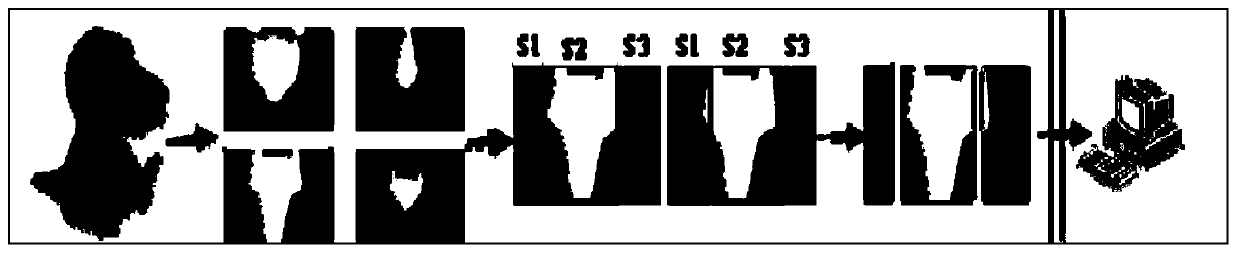

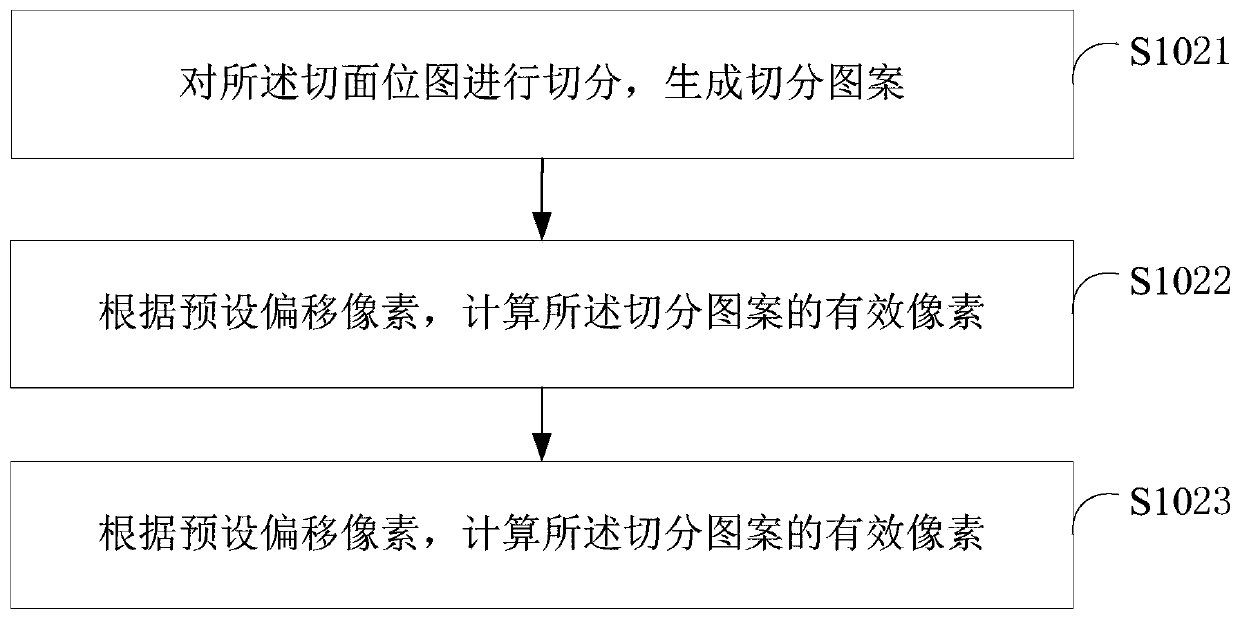

Method used

Image

Examples

Embodiment 1

[0102] For example, the DLP projector used in this embodiment has a resolution parameter of 1280*800 and a projection range of 63.36mm*39.63mm.

[0103]Print in four ways: unstitched (e), one layer divided into two moves and stitched without seams (f), setting overlapping pixels and editing the overlapping area to gray (g), and using the SS-SEM algorithm (h) to print For the sample picture, print a cuboid block with a size of 30mm*15mm*2.5mm.

[0104] After being formed by the method of unspliced (e), it will be a relatively complete piece with a smooth surface, but the size cannot be expanded, and the finished product can be used as a reference for the seam treatment effect.

[0105] Using the method of moving splicing twice in one layer without processing the seam (f), the seam error of 0.1mm is always accumulated in one place, showing a more obvious seam, and the middle splicing part is very fragile and will be damaged from molding When the countertop is removed, it brea...

Embodiment 2

[0110] For example, for a model that does not use the splicing method, the length and width of the original model are smaller than the length and width of the projection surface of the projector before it can be printed. The length, width and height of the original model are enlarged by 2 times, which exceeds the projection capacity of the projector. For the forming range, you need to use mobile splicing to print. Such as Figure 7-9 As shown, the present embodiment selects length 26.37mm, width 20.49mm, height 9.50mm (denoted as V 1 ) with a small wolf head, length 25.00mm, width 25.00mm, height 10.44mm (denoted as V 2 ) turbine and length 38.0mm, width 14.8mm, height 1.5mm (denoted as V 3 ) text relief STL model as a test sample, and the printing result is consistent with the conclusion of the effect evaluation department.

[0111] Such as Figure 10-12 As shown, the methods of printing without splicing, splicing but not eliminating seams, overlapping pixels to process s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com