Super-concentrated high-solid nanometer yellow pigment paste, preparation method and applications thereof

A beige, super-concentrated technology, applied in the direction of additive processing, etc., can solve the problems of insufficient precision of color paste, unfavorable printing of fine molds, and hidden dangers to the health of production operators, so as to improve the appearance and safety of operators. The effect of lifting and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

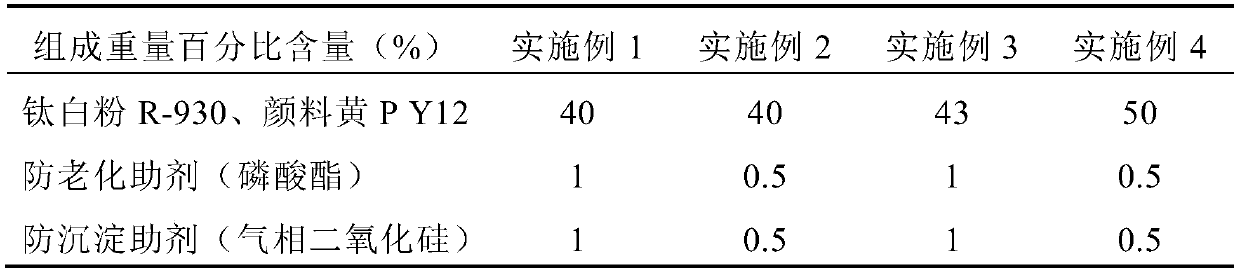

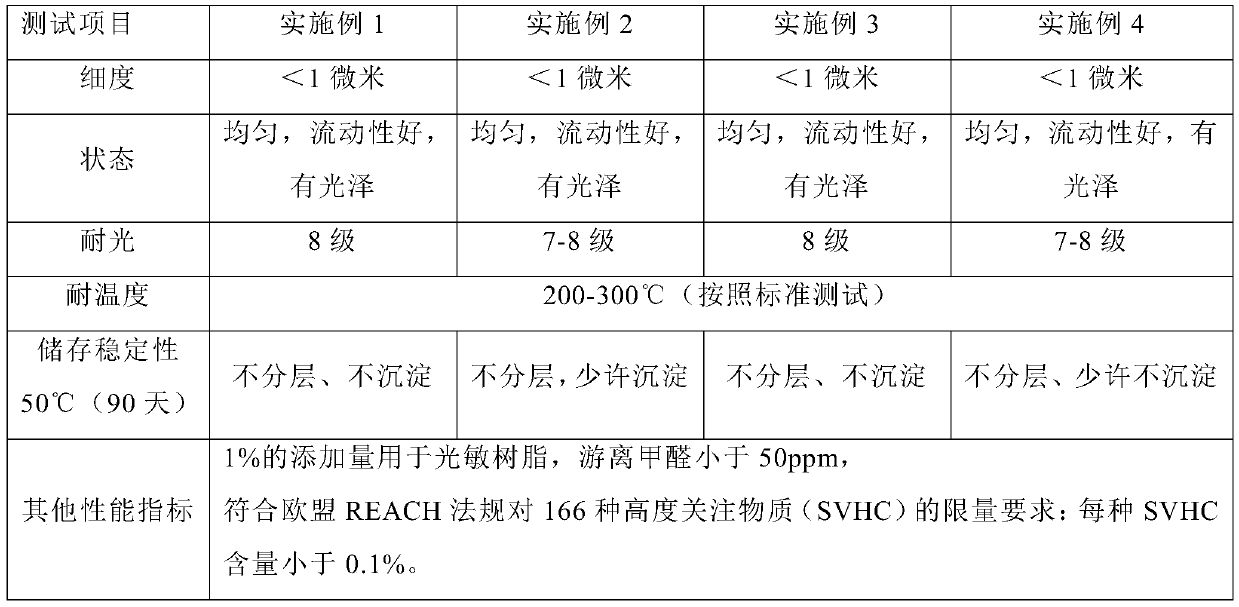

[0022] A super-concentrated high-solid nano-yellow slurry, the specific composition of the yellow slurry is shown in Table 1. The super-concentrated high-solid nano-yellow paste is prepared by the following preparation method: the inorganic and organic composite yellow pigments, anti-aging additives, anti-sedimentation additives, dispersants and liquid oil are formulated according to the weight percentage of Example 1 in Table 1. Specific weighing, adding to the container one by one, using a high-speed disperser for mixing and dispersing, the rotating speed is 1500r / min, and the mixing time is 60min. And ball mill dispersion, in which the high-speed shear dispersion cycle is 3 times, and the particle size of the mixture is detected. When the particle size is less than 900nm, the super-concentrated high-solid nano-yellow slurry can be obtained.

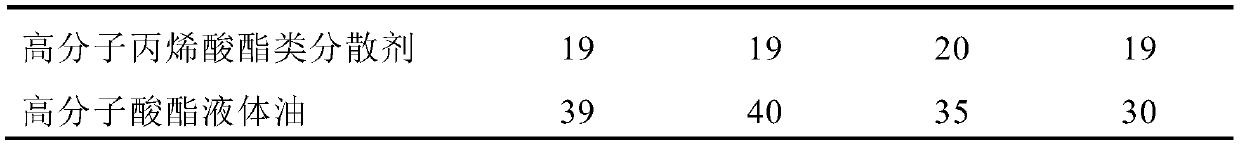

[0023] The prepared nano-yellow paste was subjected to a performance test, and the test results are shown in Table 2.

Embodiment 2

[0025] A super-concentrated high-solid nano-yellow slurry, the specific composition of the yellow slurry is shown in Table 1. The super-concentrated high-solid nano-yellow paste is prepared by the following preparation method: the inorganic and organic composite yellow pigments, anti-aging additives, anti-sedimentation additives, dispersants and liquid oil are formulated according to the weight percentage of Example 2 in Table 1. Specific weighing, adding to the container one by one, using a high-speed disperser for mixing and dispersing, the rotating speed is 1400r / min, and the mixing time is 50min. And ball mill dispersion, in which the high-speed shear dispersion cycle is 6 times, and the particle size of the mixture is detected. When the particle size is less than 900nm, the ultra-concentrated high-solid nano-yellow slurry can be obtained.

Embodiment 3

[0027] A super-concentrated high-solid nano-yellow slurry, the specific composition of the yellow slurry is shown in Table 1. The super-concentrated high-solid nano-yellow paste is prepared by the following preparation method: the inorganic and organic composite yellow pigments, anti-aging additives, anti-sedimentation additives, dispersants and liquid oil are formulated according to the weight percentage of Example 2 in Table 1. Specific weighing, adding to the container one by one, using a high-speed disperser for mixing and dispersing, the rotating speed is 1600r / min, and the mixing time is 55min. And ball mill dispersion, in which the high-speed shear dispersion cycle is 5 times, and the particle size of the mixture is detected. When the particle size is less than 900nm, the super-concentrated high-solid nano-yellow slurry can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com