Biodegradable coffee-grounds vine-imitating material

A technology of coffee grounds and biodegradation, applied in the field of new rattan weaving materials, can solve the problems of environmental pollution of rattan-like materials, and achieve the effects of excellent light transmission, excellent mechanical properties and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

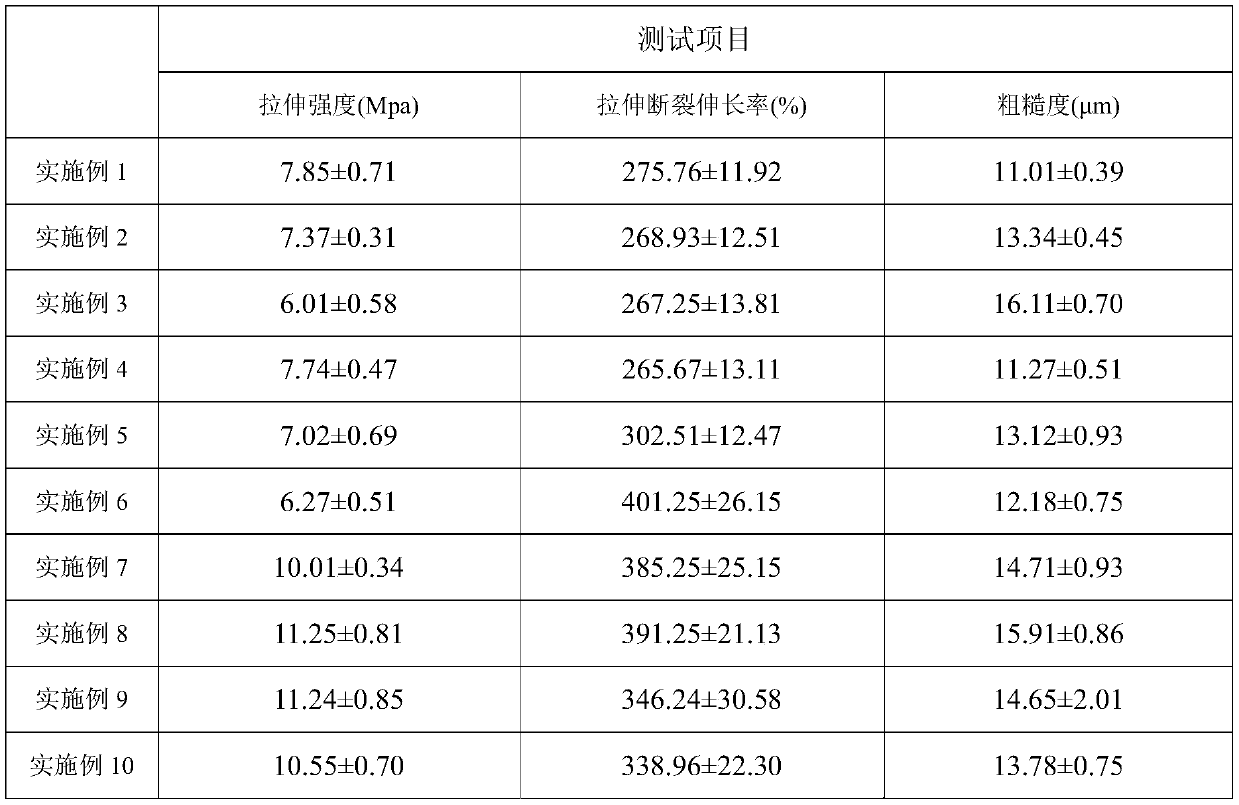

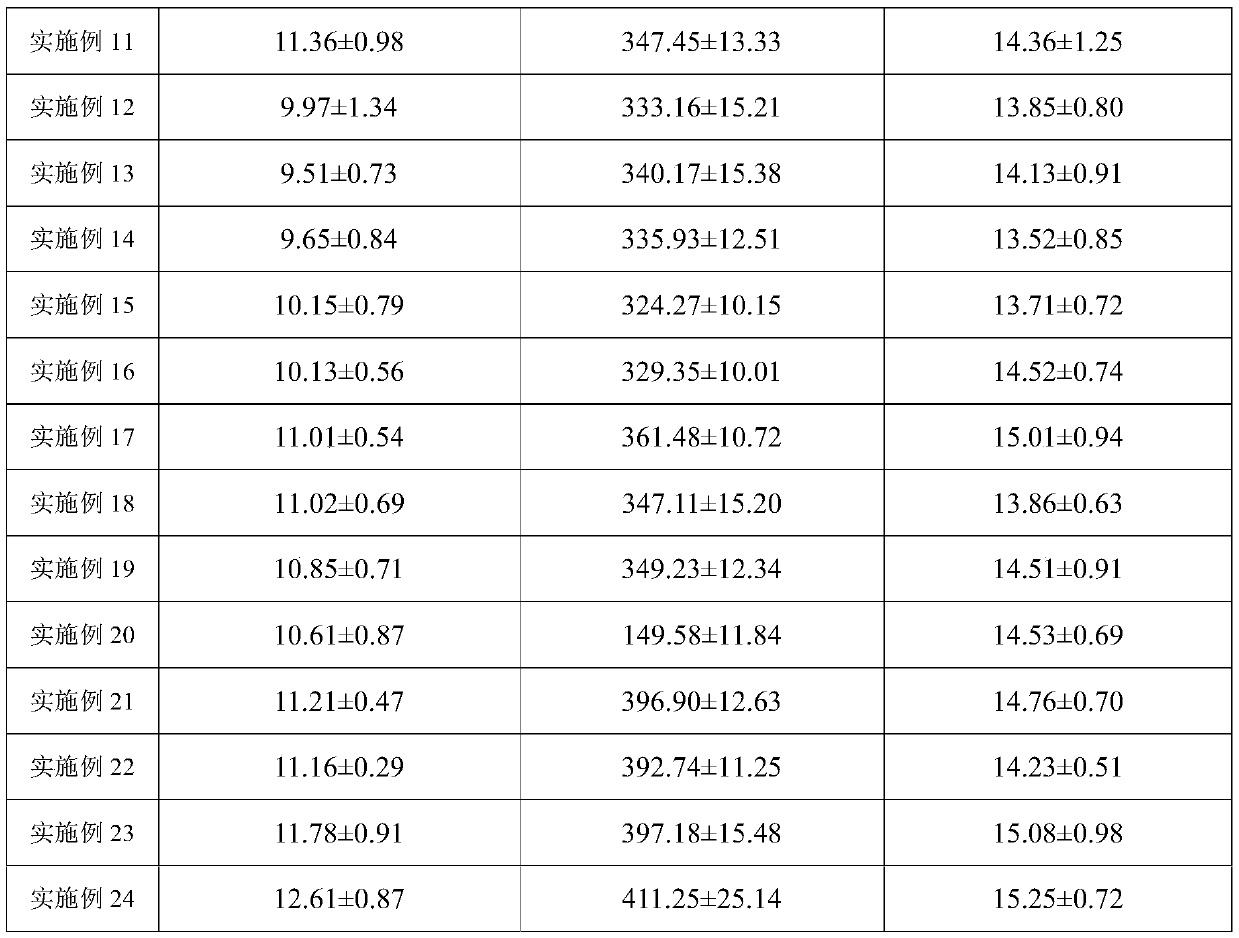

Examples

Embodiment 1

[0024] A biodegradable rattan-like material made of coffee grounds, the rattan-like material is made of the following raw materials in parts by weight: 20 parts of modified coffee grounds, 40 parts of polylactic acid (PLA), polyadipate / butylene terephthalate 5 parts of ester (PBAT), 5 parts of melt strength enhancer, 15 parts of nucleating agent, 1 part of crystallization accelerator, 5 parts of compatibilizer, 2 parts of lubricant, 0.6 part of anti-aging agent, 0.6 part of antioxidant, 0.6 parts of UV agent; the compatibilizer is ethylene-n-butyl acrylate-glycidyl methacrylate triblock copolymer (E-BA-GMA), and the melt strength enhancer is a weight ratio of 1:1 Epoxy functional group-containing material and acrylic acid series star copolymer, the lubricant is vinyl bis stearamide, low molecular weight polyethylene wax and stearic acid with a weight ratio of 1:1:1, and the antioxidant is a weight ratio of It is a 2:1 combination of hindered phenolic antioxidants and phosphite...

Embodiment 2

[0026] A biodegradable coffee grounds imitation rattan material, which is made of the following raw materials in parts by weight: 30 parts of modified coffee grounds, 40 parts of polylactic acid (PLA), polyadipate / butylene terephthalate 5 parts of ester (PBAT), 5 parts of melt strength enhancer, 15 parts of nucleating agent, 1 part of crystallization accelerator, 5 parts of compatibilizer, 2 parts of lubricant, 0.6 part of anti-aging agent, 0.6 part of antioxidant, 0.6 parts of UV agent; the compatibilizer is ethylene-n-butyl acrylate-glycidyl methacrylate triblock copolymer (E-BA-GMA), and the melt strength enhancer is a weight ratio of 1:1 Epoxy functional group-containing material and acrylic acid series star copolymer, the lubricant is vinyl bis stearamide, low molecular weight polyethylene wax and stearic acid with a weight ratio of 1:1:1, and the antioxidant is a weight ratio of It is a 2:1 combination of hindered phenolic antioxidants and phosphite antioxidants. More s...

Embodiment 3

[0028]A biodegradable rattan-like material made of coffee grounds, the rattan-like material is made of the following raw materials in parts by weight: 40 parts of modified coffee grounds, 40 parts of polylactic acid (PLA), polyadipate / butylene terephthalate 5 parts of ester (PBAT), 5 parts of melt strength enhancer, 15 parts of nucleating agent, 1 part of crystallization accelerator, 5 parts of compatibilizer, 2 parts of lubricant, 0.6 part of anti-aging agent, 0.6 part of antioxidant, 0.6 parts of UV agent; the compatibilizer is ethylene-n-butyl acrylate-glycidyl methacrylate triblock copolymer (E-BA-GMA), and the melt strength enhancer is a weight ratio of 1:1 Epoxy functional group-containing material and acrylic acid series star copolymer, the lubricant is vinyl bis stearamide, low molecular weight polyethylene wax and stearic acid with a weight ratio of 1:1:1, and the antioxidant is a weight ratio of It is a 2:1 combination of hindered phenolic antioxidants and phosphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com