Preparation method of cassava residue activated carbon

A technology of cassava residue and activated carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of cassava residue environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

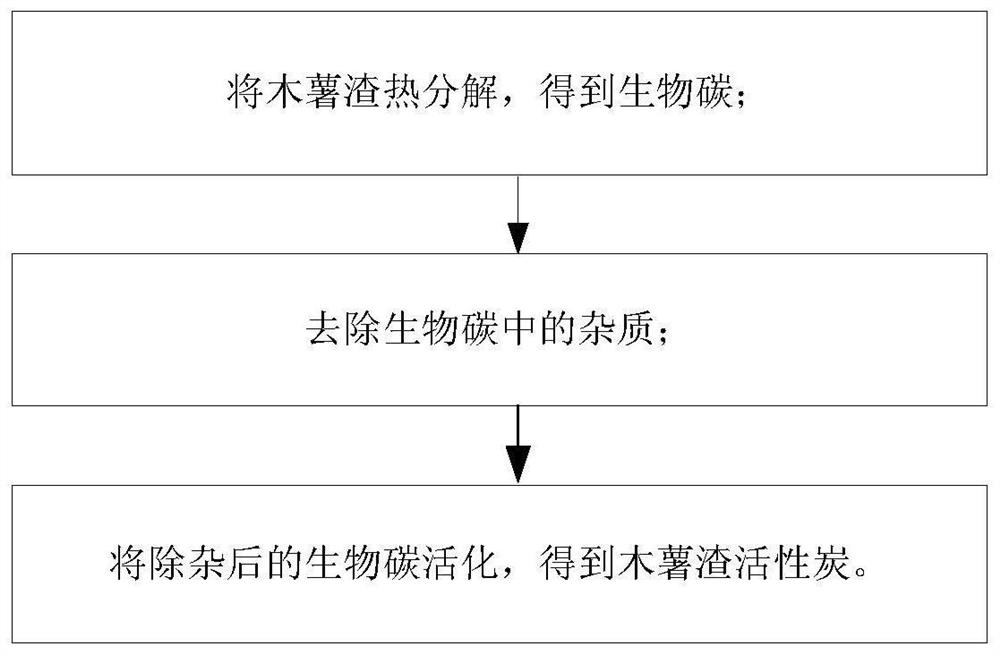

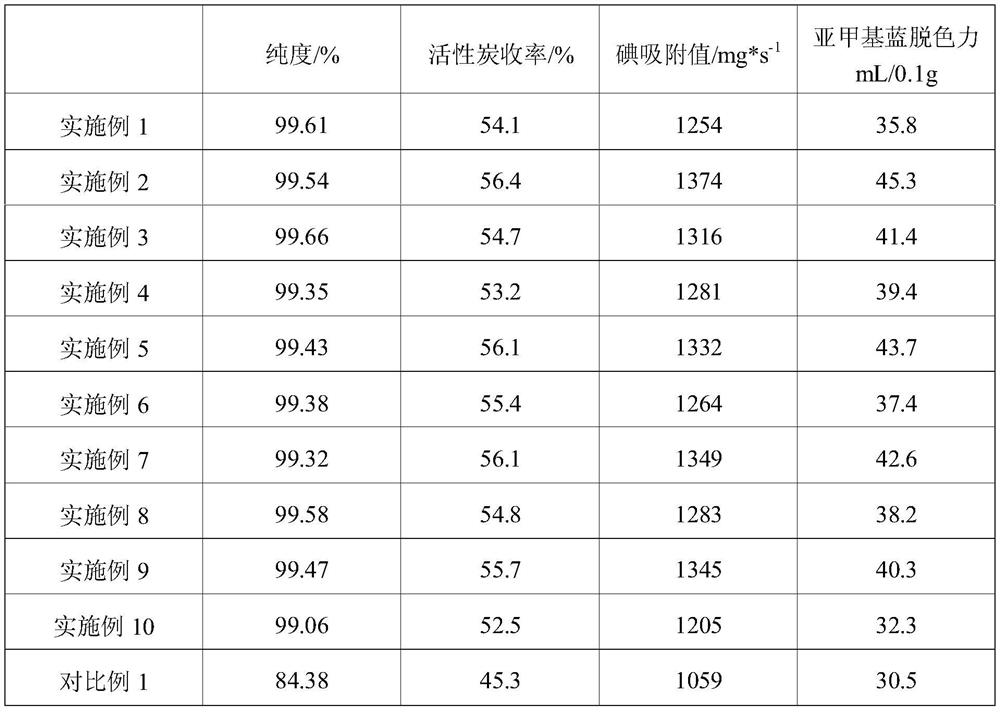

[0023] As described in the background art, the cassava residue obtained from ethanol production in the prior art is simply incinerated or composted, which not only greatly wastes resources, but also seriously pollutes the environment. In order to solve the above-mentioned technical problems, the invention provides a kind of preparation method of cassava residue activated carbon, such as figure 1 As shown, the method includes the following steps: thermally decomposing cassava residue to obtain biochar; removing impurities in the biochar; activating the removed biochar to obtain cassava residue activated carbon.

[0024] Using the method for preparing activated carbon from cassava residues provided by the present invention, thermally decompose cassava residues to obtain biochar, and then prepare high-quality activated carbon products through processes such as impurity removal and activation, which provides a new method for the prior art. A new way to deal with cassava residues i...

Embodiment 1

[0038] The preparation method of the cassava residue activated carbon provided by the present embodiment may further comprise the steps:

[0039] Weigh 2.5kg of cassava residues into an oven, dry at 105°C for 12 hours and then drop to room temperature; screen the dried cassava residues with 40 meshes, add the screened cassava residues to the fluidized bed reactor, and the cassava residues are fed The rate is 45g / h, the nitrogen flow rate is 0.5m 3 Rapid thermal decomposition occurs under the condition of 580℃ / h, the system pressure is normal pressure, and carbon monoxide, light hydrocarbons, bio-oil, bio-carbon and other products are obtained. The ash content of bio-carbon is 0.95% after cyclone dust removal, and cooled to room temperature ; Boil the above biochar with deionized water for 60min, filter to obtain solid biochar; add the filtered biochar to NaOH aqueous solution with a concentration of 2mol / L, heat and boil for 120min, filter and wash after cooling down to room t...

Embodiment 2

[0041] The difference between the preparation method of the cassava residue gac provided by the present embodiment and embodiment 1 is:

[0042] After drying at 100° C. for 15 hours, cool down to room temperature; screen the dried cassava residue with 60 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com