Preparation of biomimetic skeletal muscle composite tissue by multi-channel extrusion 3D bioprinting

A bioprinting, composite tissue technology, used in tissue regeneration, animal cells, prostheses, etc., can solve problems such as inability to combine, provide bone lesions, and muscles have no function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

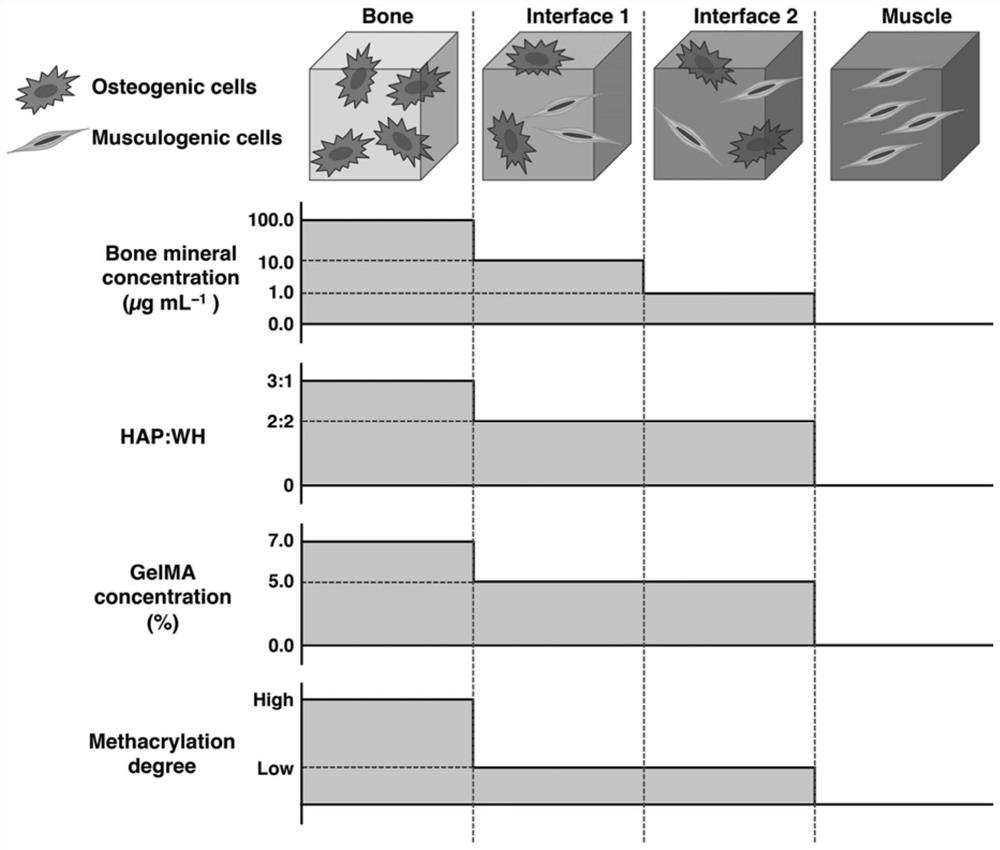

[0066] A bionic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting, prepared by the following preparation method:

[0067] S1. By dropping MA into the gelatin aqueous solution, the substitution degree of MA in the bionic bone was 81.4%; the bionic periosteum was 19.7%; the bionic sarcolemma was 19.7%; the bionic muscle was 19.7%.

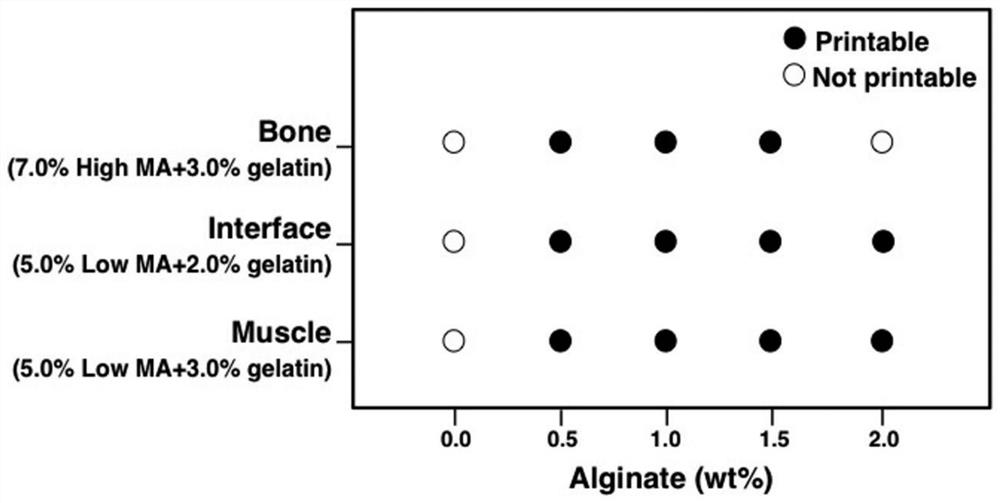

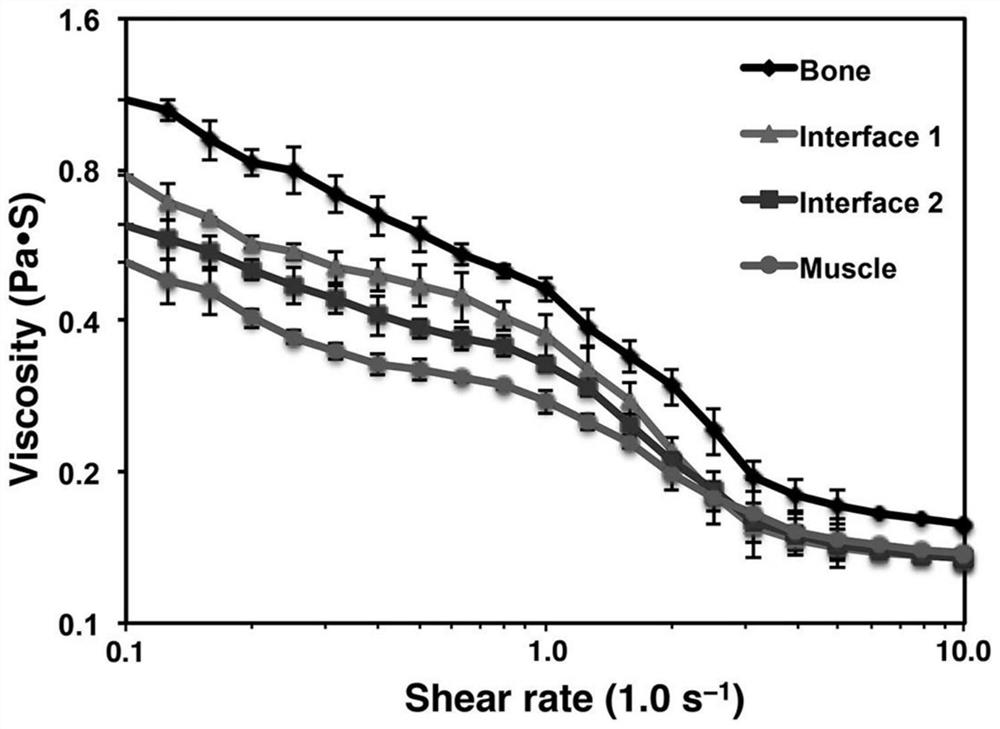

[0068] S2. The concentration of GelMA in the bionic bone is 7.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 3.0% ( W / V ); the concentration of GelMA in the bionic periosteum scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 2.0% ( W / V ); the concentration of GelMA in the biomimetic sarcolemma scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 2.0% ( W / V ); the concentration of GelMA in the bionic muscle scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a g...

Embodiment 2

[0075] A bionic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting, prepared by the following preparation method:

[0076] S1. By dropping MA into the gelatin aqueous solution, the substitution degree of MA in the bionic bone is 90.0%; the bionic periosteum is 25.0%; the bionic sarcolemma is 25.0%; the bionic muscle is 25.0%.

[0077] S2. The concentration of GelMA in the bionic bone is 6.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 3.0% ( W / V ); the concentration of GelMA in the bionic periosteum scaffold was 4.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 2.0% ( W / V ); the concentration of GelMA in the biomimetic sarcolemma scaffold was 4.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and a gelatin concentration of 2.0% ( W / V ); the concentration of GelMA in the bionic muscle scaffold was 4.0% ( W / V), the concentration of SA is 0.5% ( W / V ) and gelatin ...

Embodiment 3

[0084] A biomimetic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting is prepared by the following preparation method:

[0085] S1. By adding MA to gelatin aqueous solution, the substitution degree of MA in bionic bone is 81.4%; bionic periosteum is 19.7%; bionic sarcolemma is 19.7%; bionic muscle is 19.7%.

[0086] S2, the concentration of GelMA in the bionic bone is 7.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and gelatin at a concentration of 4.0% ( W / V ); the concentration of GelMA in the biomimetic periosteal scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and gelatin at a concentration of 3.0% ( W / V ); the concentration of GelMA in the bionic sarcolemma scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and gelatin at a concentration of 3.0% ( W / V ); the concentration of GelMA in the bionic muscle scaffold was 5.0% ( W / V ), the concentration of SA is 0.5% ( W / V ) and gelatin at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com