High-efficiency sludge discharge sedimentation tank

A technology for sedimentation tanks and sludge discharge tanks, applied in the direction of sedimentation separation, settling tanks, settling tanks, etc., can solve the problems of increasing water production costs, increasing energy consumption for sludge treatment, occupying land resources, etc., and achieves saving floor space, Improve mud discharge efficiency and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

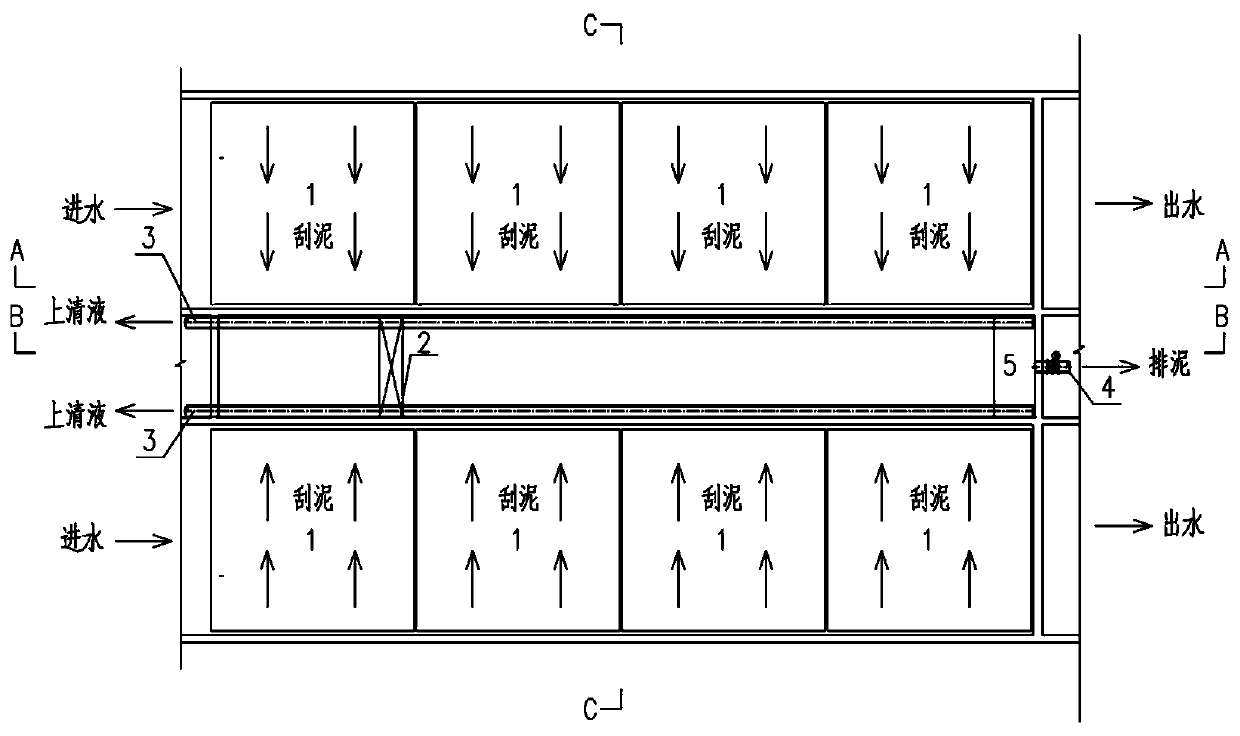

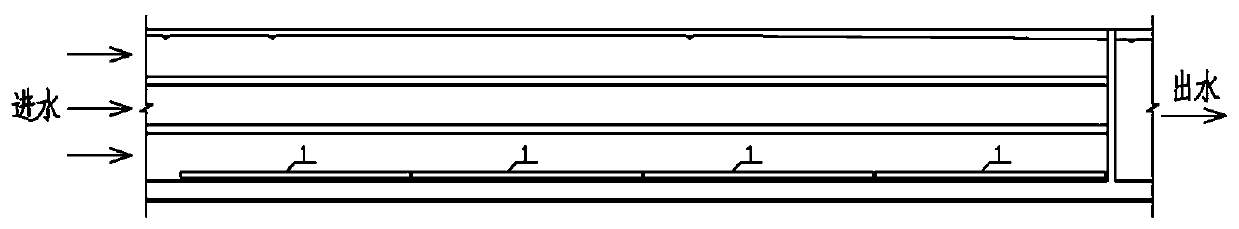

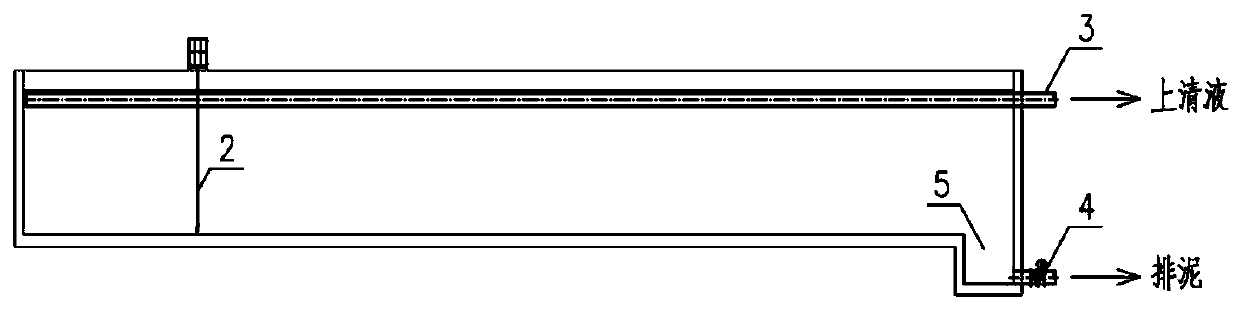

[0020] This embodiment of the present invention is a novel high-efficiency mud-discharging sedimentation tank, which is mainly composed of a multi-layer sedimentation tank and a central mud-discharging tank.

[0021] Multi-layer sedimentation tanks are set on both sides, and the center is separated by a sludge discharge tank. Bottom mud scrapers are used in each sedimentation area of the multi-layer sedimentation tank. The mud scrapers can be reciprocating, chain or other types, but the mud scraping direction is to scrape mud from both sides to the middle, and finally scrape the bottom mud to the central mud discharge tank. Since the function of the central sludge discharge area is to receive the bottom sludge of each layer, the sludge discharge process of each layer of sedimentation tank does not affect the normal operation of other layers of sedimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com