Preparation method of NiFeBMo-based opening and closing locker multilayer composite structure material

A multi-layer composite and structural material technology, applied in the field of material synthesis of mechanical parts, can solve the problems of friction and cracking on the surface of the opening and closing locker, reduced use efficiency, reduced locking pressure, etc., and achieves excellent thermal conductivity and high efficiency. , easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

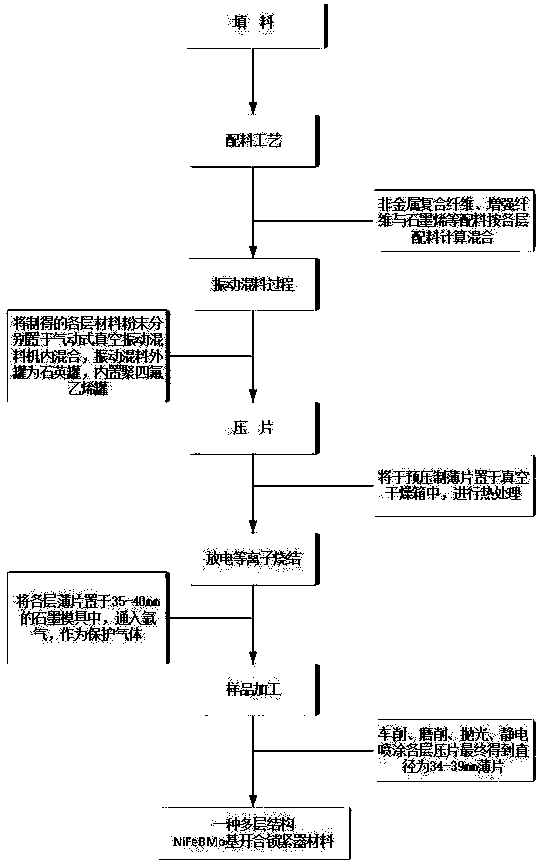

Method used

Image

Examples

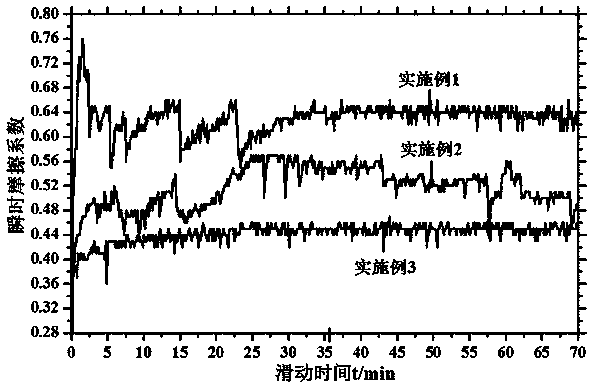

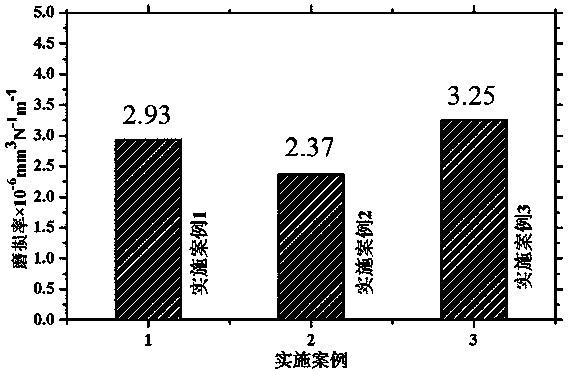

Embodiment 1

[0031] A NiFeBMo-based opening and closing locker multi-layer composite structure material, which is based on NiFeBMo material, lanthanum vanadium allanite, white vermiculite, TIC-MO, TiN as anti-wear agent, carbon fiber, aluminum borate whisker, Multilayer composite structure material of NiFeBMo-based opening and closing locker with sisal fiber as reinforcement. The multilayer composite structural material of NiFeBMo-based opening and closing locker is formed by compounding the thickness of each layer from the top layer to the bottom layer and the lubrication control material increasing layer by layer.

[0032] The preparation method of the above-mentioned NiFeBMo-based opening and closing locker multilayer composite structure material specifically includes the following steps:

[0033] 1) Calculation and preparation of raw materials for each layer structure. The composition and content of the top layer include 6wt.% NiFeBMo matrix alloy, 31wt.% antiwear agent, 10wt.% therma...

Embodiment 2

[0042] A NiFeBMo-based opening and closing locker multi-layer composite structure material is based on NiFeBMo as the matrix material, lanthanum vanadium allanite, white vermiculite, TIC-MO, TiN as anti-wear agents, carbon fiber, aluminum borate whisker, sisal Fiber is a reinforcing agent. The multi-layer composite structure material of NiFeBMo-based opening and closing locker is formed by compounding and the thickness of each layer is increased layer by layer from the top layer to the bottom layer, and the lubrication control material is also increased layer by layer.

[0043] The preparation method of the above-mentioned NiFeBMo-based opening and closing locker multilayer composite structure material specifically includes the following steps:

[0044] 1) Calculation and preparation of raw materials for each layer structure. The composition and content of the top layer include 8wt.% NiFeBMo-based alloy, 39wt.% antiwear agent, 14wt.% thermal conductivity agent, 21wt.% reinfor...

Embodiment 3

[0053] A NiFeBMo-based opening and closing locker multi-layer composite structure material is based on NiFeBMo material, lanthanum vanadium allanite, white vermiculite, TIC-MO, TiN are anti-wear agents, carbon fiber, aluminum borate whisker, sisal The fiber is the reinforcement composite material. The multi-layer composite structure material of NiFeBMo-based opening and closing locker is formed by compounding and the thickness of each layer is increased layer by layer from the top layer to the bottom layer, and the lubrication control material is also increased layer by layer.

[0054] The preparation method of the above-mentioned NiFeBMo-based opening and closing locker multilayer composite structure material specifically includes the following steps:

[0055] 1) Calculation and allocation of structural raw materials for each layer. The composition and content of the top layer include 10wt.% NiFeBMo matrix alloy, 42wt.% antiwear agent, 18wt.% thermal conductivity agent, 14wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com