Graphene electric heating module and system

A graphene and electric heating technology, applied in the field of heating, can solve the problems of air source heat pumps such as low environmental pollution, high electric heat conversion efficiency, and adverse health effects, and achieve the effect of reducing the amount of renovation projects, reducing weight, and benefiting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In the description of the present invention, unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection, a detachable connection, or an integrated Connection; it can be a direct connection or an indirect connection through an intermediary, and it can be an internal connection between two elements. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

[0042] Unless otherwise specified, the terms "center", "top", "bottom", "top", "bottom", "left", "right", "vertical", "horizontal", "portrait", "landscape ", "inner", "outer" and other indicated orientations or positional relationships are based on the orientations or positional relationships shown in the drawings, which are only for the convenience of describing the present invention and simplifying the description, rath...

Embodiment 1

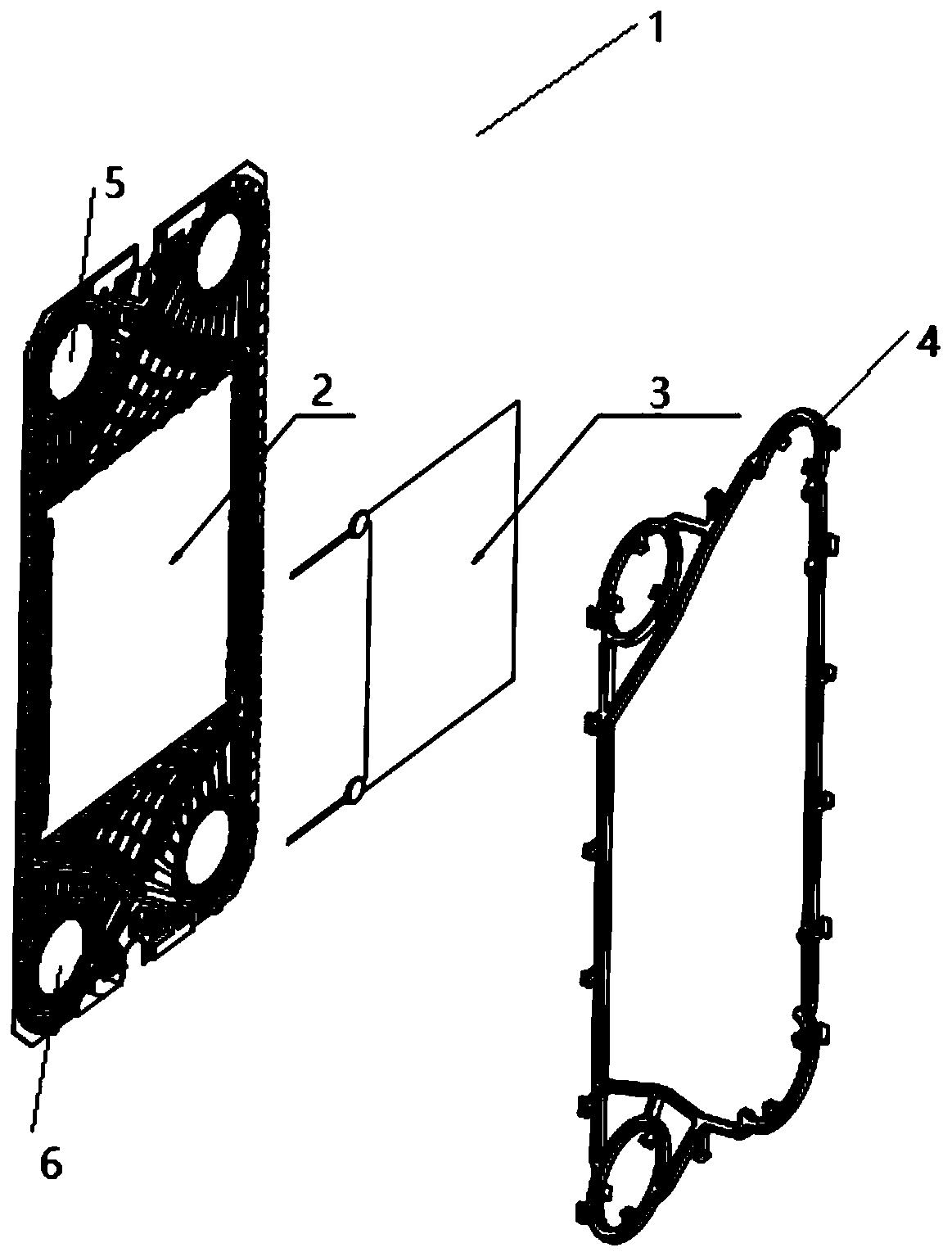

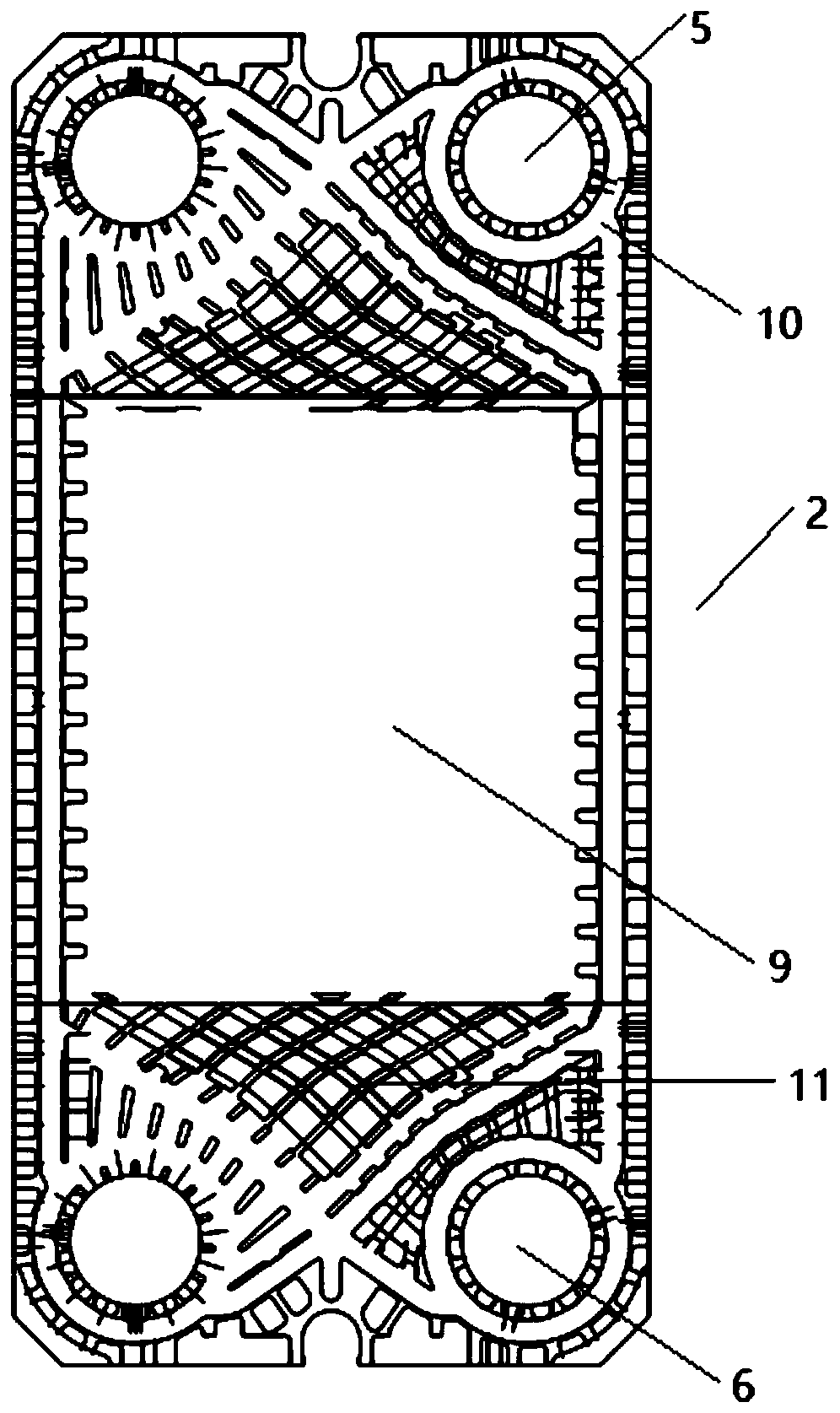

[0054] Such as figure 1 As shown, the graphene electrothermal module 1 of this embodiment includes a heat conducting plate 2, a graphene electrothermal film 3 and a seal 4, and the graphene electrothermal film 3 includes a graphene heating layer, an electrode and a protective layer, and the graphene The heating layer is 2 layers of graphene. The graphene electrothermal film 3 is arranged on the heat conduction plate 2, and the graphene electrothermal film 3 is connected with wires to be energized to generate heat, and the electrothermal film is provided with a temperature sensor. There are two water outlets 5 on the top of the heat conducting plate 2, and two water inlets 6 on the bottom. The two sealing rings on the left side of the sealing member 4 correspond to the positions of the water outlet 5 and the water inlet 6 on the left side respectively.

Embodiment 2

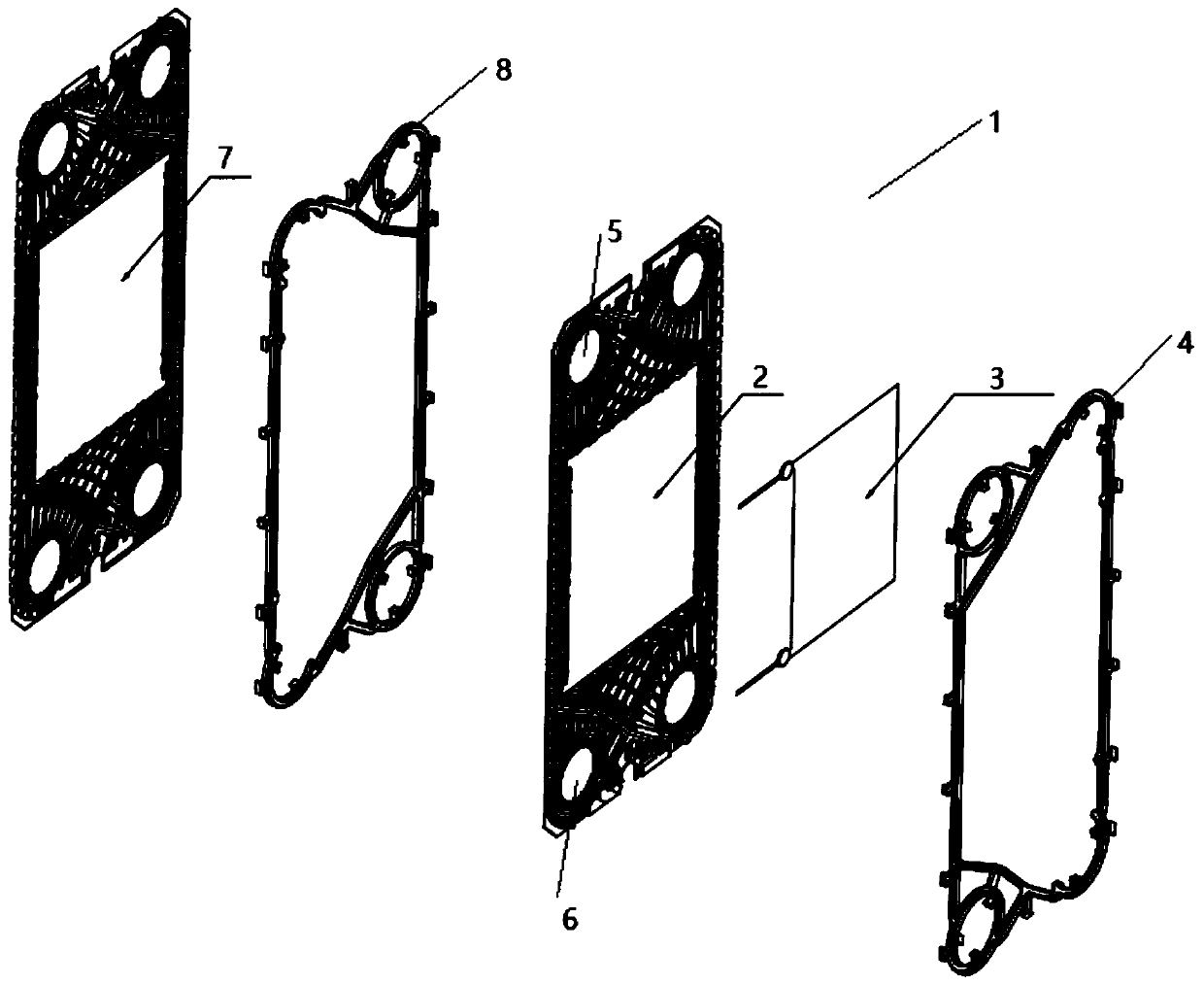

[0056] Such as figure 2 As shown, the graphene electrothermal module 1 of this embodiment includes a heat dissipation plate 7 , a second sealing member 8 , a heat conducting plate 2 , a graphene electrothermal film 3 and a sealing member 4 placed in sequence. The graphene electrothermal film 3 includes a graphene heating layer, an electrode and a protective layer, and the graphene heating layer is 3 layers of graphene. The graphene electrothermal film 3 is arranged on the heat conduction plate 2, and the graphene electrothermal film 3 is connected with wires to be energized to generate heat, and the electrothermal film is provided with a temperature sensor. Both the heat dissipation plate 7 and the heat conduction plate 2 are provided with a liquid outlet and a liquid inlet, the positions of the liquid outlet on the heat dissipation plate 7 and the liquid outlet on the heat conduction plate 2 are consistent, The positions of the liquid inlet and the liquid inlet on the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com