Preparation method of flexible biological memristor for neurosynaptic bionics

A neural synapse and memristor technology, which is applied in the field of preparation of flexible biological memristors, can solve the problems such as the number of times of erasing and writing and the switching ratio need to be further improved, the time of data retention is short, the number of times of writing and erasing is small, etc. Achieve the effect of reducing leakage paths and invalid defects, long data retention time, and low operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

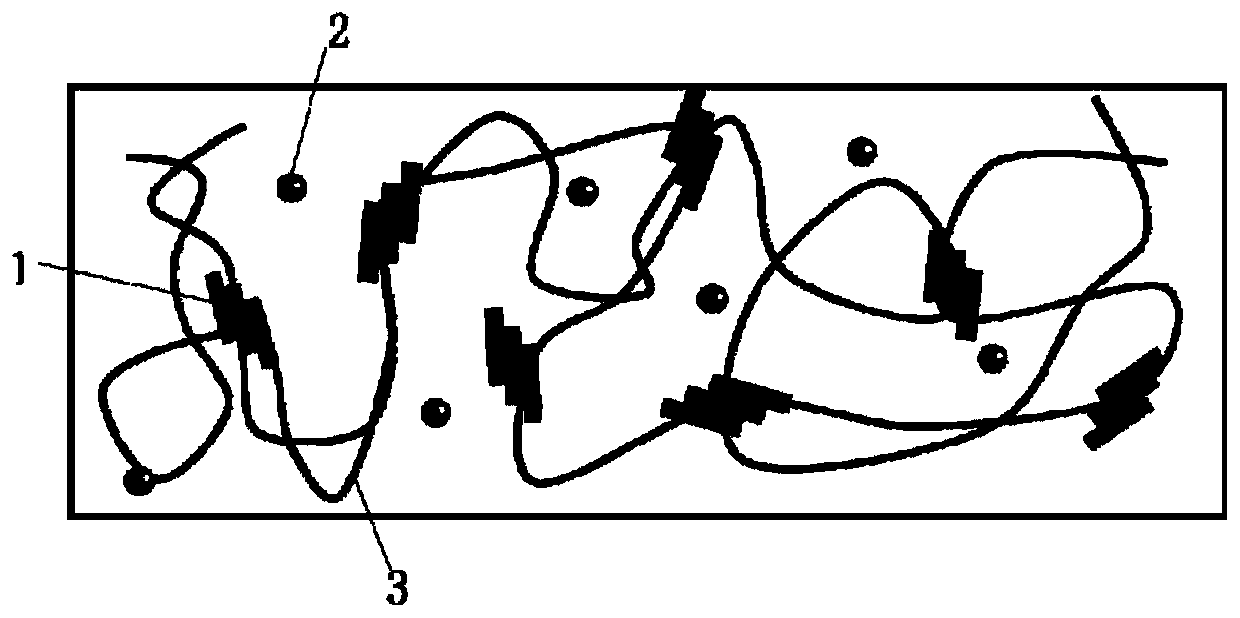

[0037] A method for preparing a flexible biomemristor for synaptic bionics, the specific steps of which are:

[0038] (1) Preparation of mixed solution: degumming, dissolving, dialysis and concentration of silkworm cocoons were performed sequentially to obtain silk fibroin aqueous solution; adding AgNO to the silk fibroin aqueous solution 3 , making silk fibroin and AgNO 3 The concentration is the mixed solution of 3wt% and 2mmol / L respectively;

[0039] (2) Preparation of composite silk fibroin film: Utilize a spin coater to coat the mixed solution prepared in step (1) on the ITO conductive layer with a thickness of 100nm at a speed of 2800rpm, and the coating time is 40s to obtain a thickness of 190nm composite silk fibroin film, wherein the conductive layer is supported by a PET substrate with a thickness of 1mm;

[0040] (3) Preparation of flexible bio-memristor: Soak the composite silk fibroin film in an ethanol aqueous solution with a volume concentration of 85% for 13...

Embodiment 2

[0048] A method for preparing a flexible biomemristor for synaptic bionics, the specific steps of which are:

[0049] (1) Preparation of mixed solution: degumming, dissolving, dialysis and concentration of silkworm cocoons in sequence to obtain silk fibroin aqueous solution; adding CaCl to the silk fibroin aqueous solution 2 , making silk fibroin and CaCl 2 The concentration is the mixed solution of 3wt% and 2mmol / L respectively;

[0050] (2) Preparation of composite silk fibroin film: Utilize a spin coater to coat the mixed solution prepared in step (1) on the Ag conductive layer with a thickness of 95nm at a speed of 2800rpm, and the film coating time is 40s to obtain a thickness of 185nm composite silk fibroin film, wherein the conductive layer is supported by a PET substrate with a thickness of 1mm;

[0051] (3) Preparation of flexible biomemristor: Soak the composite silk fibroin film in an ethanol aqueous solution with a volume concentration of 85% for 130 minutes, and...

Embodiment 3

[0053] A method for preparing a flexible biomemristor for synaptic bionics, the specific steps of which are:

[0054] (1) Preparation of mixed solution: degumming, dissolving, dialysis and concentration of silkworm cocoons in turn to obtain silk fibroin aqueous solution; adding FeSO to the silk fibroin aqueous solution 4 , making silk fibroin and FeSO 4 The concentration is the mixed solution of 3wt% and 2mmol / L respectively;

[0055] (2) Preparation of composite silk fibroin film: Utilize a spin coater to coat the mixed solution prepared in step (1) on the Au conductive layer with a thickness of 103nm at a speed of 2800rpm, and the coating time is 40s to obtain a thickness of 185nm composite silk fibroin film, wherein the conductive layer is supported by a PET substrate with a thickness of 1mm;

[0056](3) Preparation of flexible bio-memristor: Soak the composite silk fibroin film in an ethanol aqueous solution with a volume concentration of 85% for 130 minutes, and then pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com