High-accuracy filtering device and method for aviation kerosene

A filtering device and technology for aviation kerosene, which are applied in the direction of refining by filtering, filtering and separating, and separating methods, can solve problems such as the difficulty in effectively removing filamentous gum in aviation kerosene, and improve the pollution-holding capacity and service life. , the effect of improving the pollution-holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

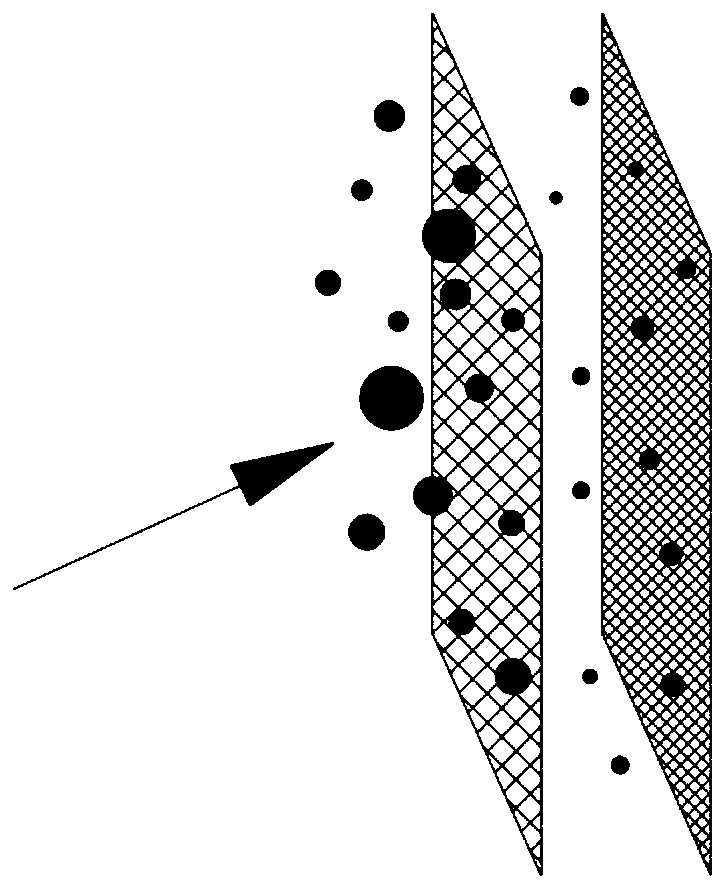

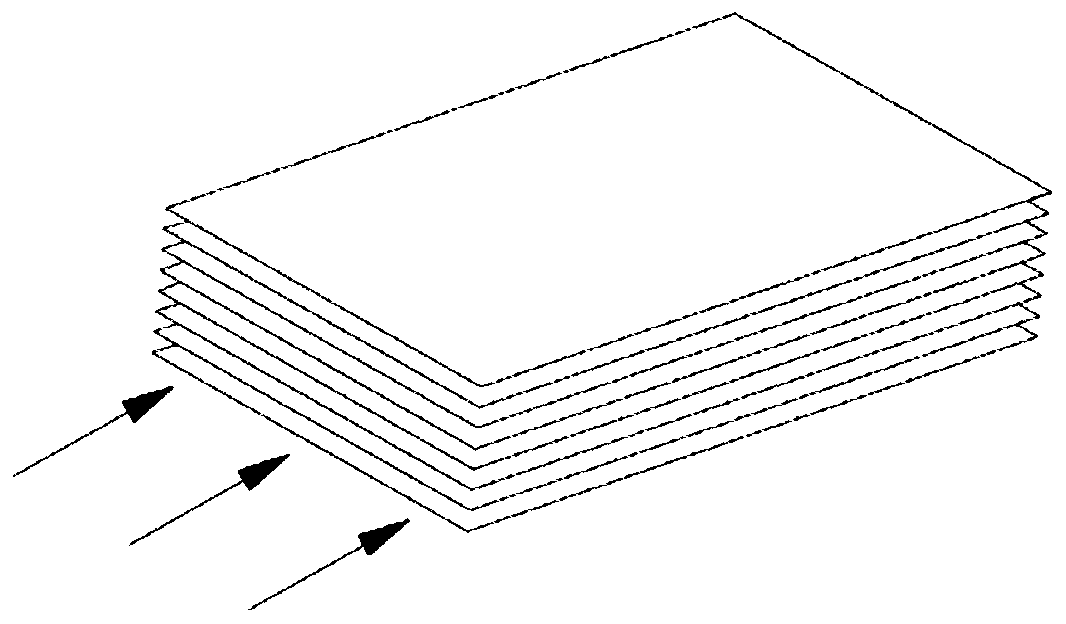

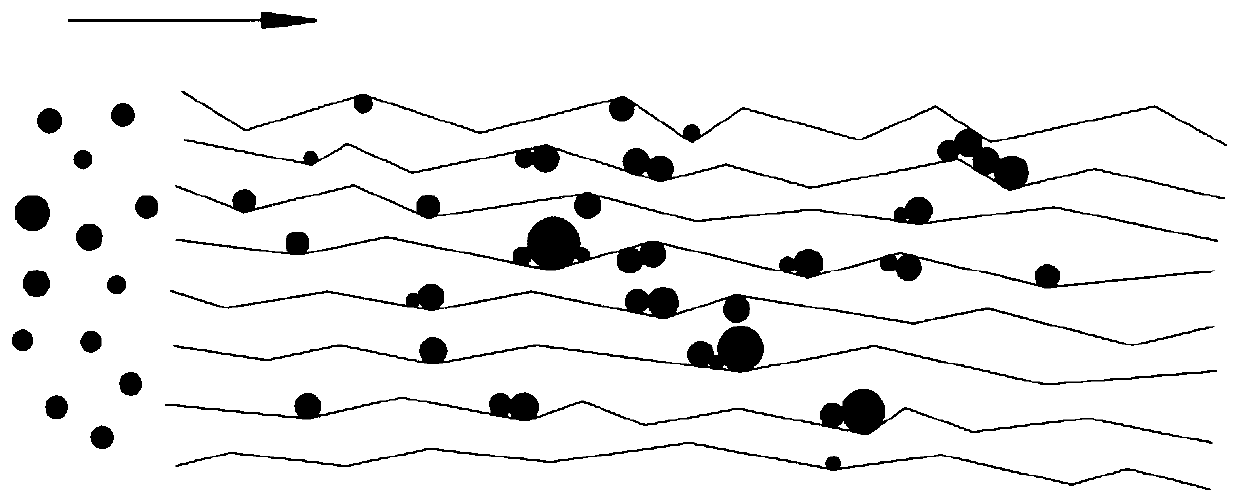

[0033] This embodiment provides a high-precision filtration method for aviation kerosene. The basic principle of the method is: stack multiple layers of filter paper, let the filtrate pass parallel to the surface of the filter paper, and use the tiny gaps between the filter papers to filter the filtrate. On the other hand, due to the rough surface of the filter paper, when the filtrate passes through the filter paper along the gap between the filter papers, it will collide with the upper and lower filter papers, and the impurities will be adsorbed on the filter paper fibers.

[0034] Such as Figure 4 As shown, the filter device provided in this embodiment includes a housing, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com