the w 3 modified bi 2 o 2 co 3 Preparation method of photocatalyst and its application

A photocatalyst and modification technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems that are not conducive to the industrialization process, save energy consumption, and reduce production processes , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

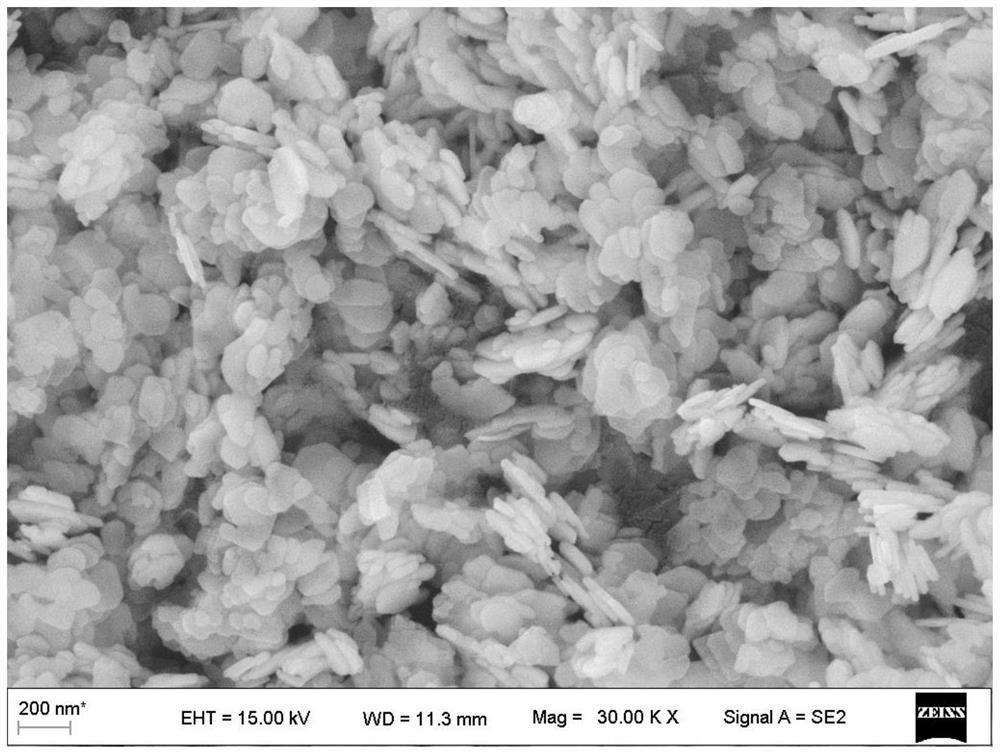

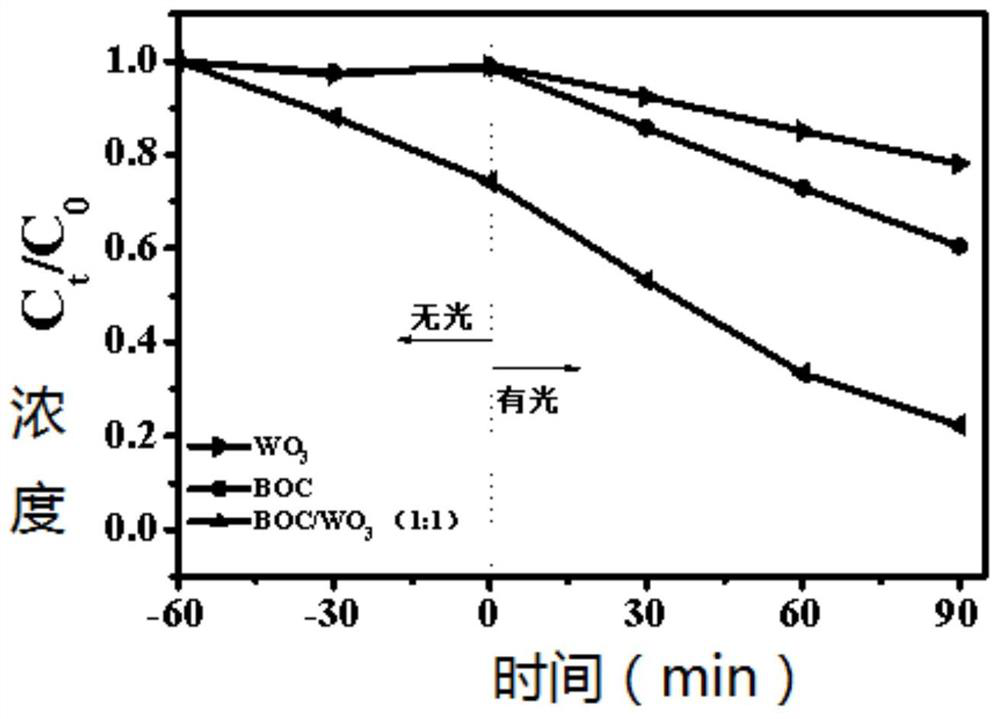

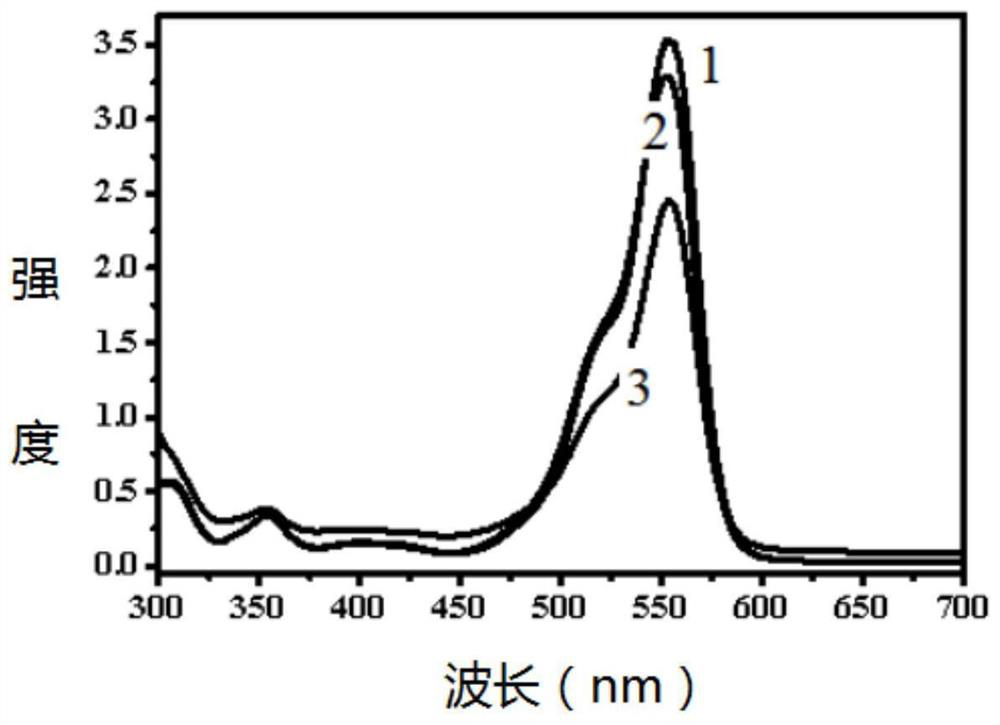

[0036] A kind of WO 3 Modified Bi 2 o 2 CO 3 The preparation of the photocatalyst comprises the following steps. The WO 3 with Bi(NO 3 ) 3 The ratio of the amount of substances is 1:1.

[0037] (1) Take 1mmol WO 3 Dissolve in 30 mmol of deionized water, and stir magnetically for 30 min at a stirring speed of 700 r / min to prepare solution A.

[0038] (2) Take 1mmol Bi(NO 3 ) 3 Dissolve in 20mmol deionized water, stir magnetically for 30min at a stirring speed of 700r / min, after mixing evenly, add 20ml of HNO with a concentration of 65% 3 solution, solution B was prepared.

[0039] (3) Slowly pour solution B into solution A, add 0.2mmol nano-SiO 2 , sonicated for 30min, after it was completely dissolved, add 2mmolNa 2 CO 3 solution and 0.2 mmol of polyvinylpyrrolidone to prepare solution C.

[0040] (4) Heat solution C in a water bath, stir for 3 hours, collect the precipitate by vacuum filtration, wash twice with deionized water and absolute ethanol, dry at 60°C ...

Embodiment 2

[0045] A kind of WO 3 Modified Bi 2 o 2 CO 3 The preparation of the photocatalyst comprises the following steps. The WO 3 with Bi(NO 3 ) 3 The ratio of the amount of substances is 0.6:1.

[0046] (1) Take 1.2mmol WO 3 Dissolve in 36 mmol of deionized water, and stir magnetically for 30 min at a stirring speed of 800 r / min to prepare solution A.

[0047] (2) Take 2mmol Bi(NO 3 ) 3 Dissolve in 40mmol deionized water, stir magnetically for 30min at a stirring speed of 800r / min, after mixing evenly, add 20ml of 65% HNO 3 solution, solution B was prepared.

[0048] (3) Slowly pour solution B into solution A, add 0.4mmol nano-SiO 2 , sonicated for 30 min, and after it was completely dissolved, 4 mmol of 38% ammonia solution and 0.4 mmol of polyvinylpyrrolidone were added to prepare solution C.

[0049] (4) Heat solution C in a water bath, stir for 3 hours, collect the precipitate by vacuum filtration, wash twice with deionized water and absolute ethanol, dry at 80°C for...

Embodiment 3

[0053] A kind of WO 3 Modified Bi 2 o 2 CO 3 The preparation of the photocatalyst comprises the following steps. The WO 3 with Bi(NO 3 ) 3 The ratio of the amount of substances is 0.8:1.

[0054] (1) Take 0.8mmol WO 3 Dissolve in 24 mmol of deionized water, and stir magnetically for 30 min at a stirring speed of 500 r / min to prepare solution A.

[0055] (2) Take 1mmol Bi(NO 3 ) 3 Dissolve in 20mmol of deionized water, stir magnetically for 30min at a stirring speed of 500r / min, after mixing evenly, add 20ml of HNO with a concentration of 65% 3 solution, solution B was prepared.

[0056] (3) Slowly pour solution B into solution A, add 0.2mmol nano-SiO2, ultrasonically shake for 30min, and after it is completely dissolved, add 2mmol NaOH and 0.5mmol polyvinylpyrrolidone to prepare solution C.

[0057] (4) Heat solution C in a water bath, stir for 3 hours, collect the precipitate by vacuum filtration, wash twice with deionized water and absolute ethanol, dry at 80°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com