A kind of lng refrigerated vehicle which recycles heat energy and cold energy

A technology of cold energy recovery and refrigerated vehicles, which is applied in the field of LNG refrigerated vehicles, can solve problems such as waste of cooling capacity, achieve the effect of reducing operating costs and increasing the supply of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

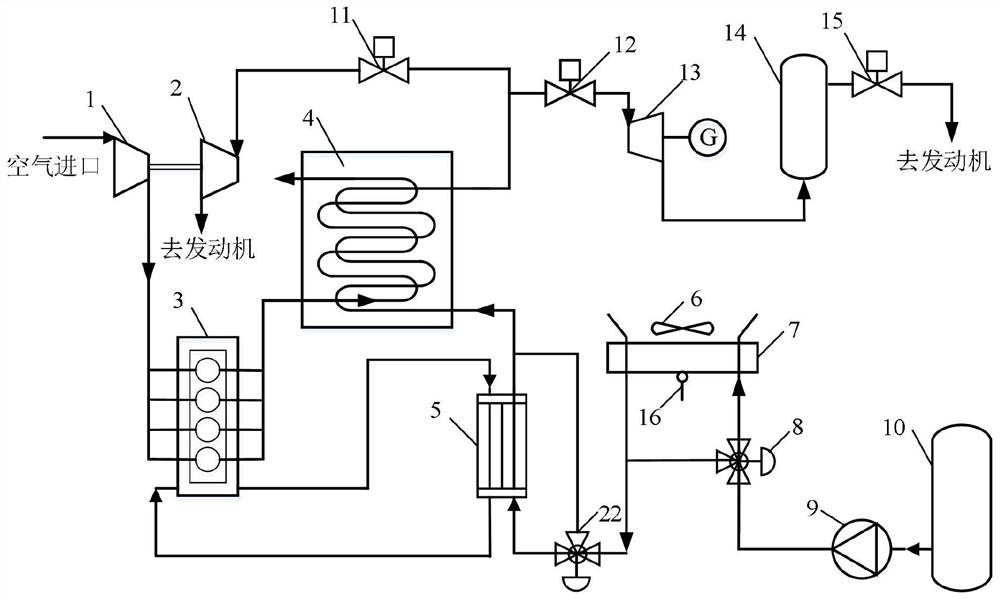

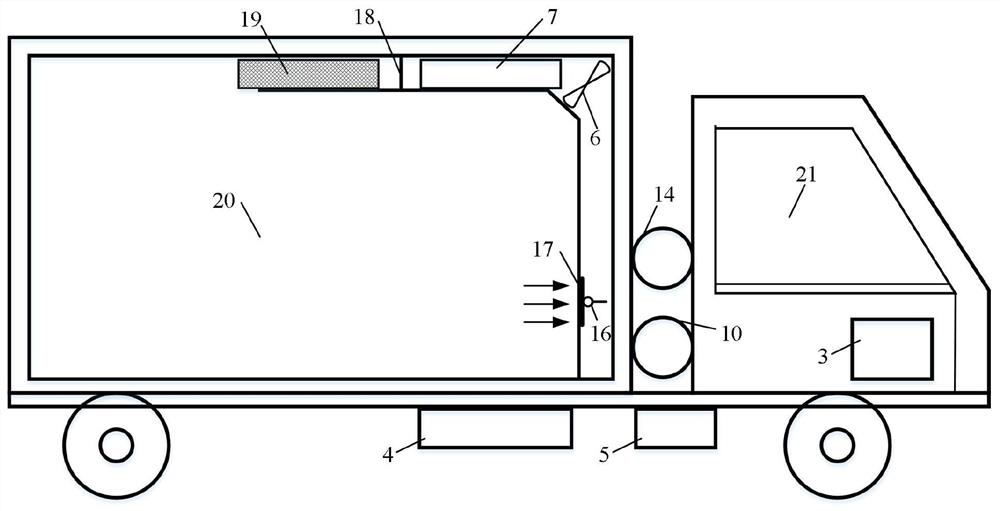

[0031] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0032] The LNG refrigerated vehicle of the present invention includes:

[0033] Turbocharger 1: used for engine intake boost;

[0034] Phase change heat storage device 4: used for engine exhaust waste heat recovery;

[0035] The first heat exchanger 5: used for recovery of waste heat from engine cooling water;

[0036] The second heat exchanger 7: used to provide cooling capacity for the compartment of the refrigerated truck;

[0037] Natural gas supply unit: used to drive the first expander 2 to rotate and drive the turbocharger 1 to rotate, and to drive the second expander 13 to rotate to generate electricity for refrigerated vehicles;

[0038] The cold energy in the liquefied natural gas in the natural gas supply unit is recovered by the second heat exchanger 7 and then heated by the first heat exchanger 5 and the phase change heat storage device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com