Printing and dyeing wastewater total nitrogen removal process

A technology for printing and dyeing wastewater and nitrogen removal, applied in the direction of aerobic process treatment, water pollutants, water/sewage treatment, etc., can solve the problems of long cycle time, low treatment efficiency, high cost, etc., to improve metabolic capacity, treat Efficient, growth-promoting and reproductive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]A total nitrogen removal process for printing and dyeing wastewater disclosed by the invention comprises the following process steps:

[0047] S1: Pass the printing and dyeing wastewater into the grid well to remove large particles;

[0048] S2: The waste water passing through the grid well is passed into the regulating tank for homogenization and equalization;

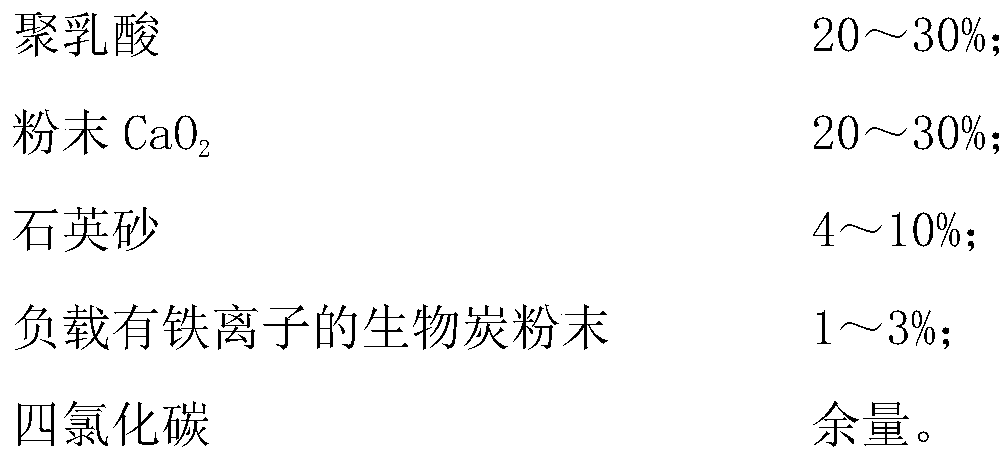

[0049] S3: The sewage after passing through the adjustment tank is passed into the pre-treatment tank for pre-treatment. The pre-treatment tank is added with a pre-treatment agent, and the pre-treatment aid includes the following components in parts by weight:

[0050] 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid;

[0051] 15 parts of alkaline additives;

[0052] 160 parts of water.

[0053] Alkaline auxiliary agent adopts the sodium hydroxide solution of 20% mass concentration.

[0054] S4: carry out biological contact oxidation reaction through the wastewater passing through the regulating...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap