Application of microreactor for preparation of ethylicin and production process of ethylicin

A micro-reactor, the technology of ethalicin, applied in the direction of control/regulation process, chemical/physical/physical-chemical reactor, chemical instruments and methods, etc., can solve the difficulty of ethalicin production process and equipment to achieve high efficiency, environmental protection, It is difficult to achieve the effect of industrialization, and it is difficult to achieve the problems of industrial production, so as to achieve the effect of production process safety, efficiency improvement, and concentration improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

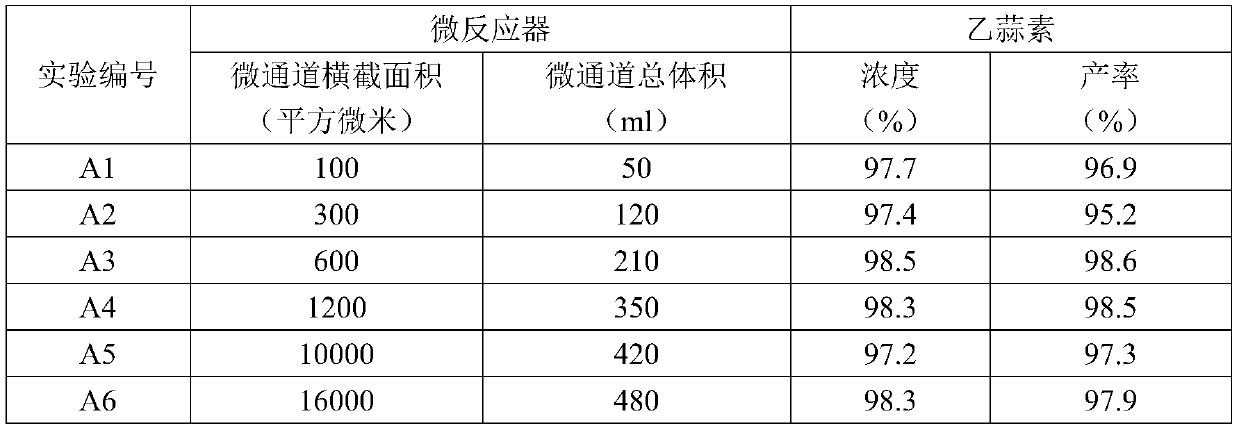

Embodiment 1

[0041] Raw material is that the concentration is 85% diethyl disulfide solution, glacial acetic acid and 45% nitric acid solution, glacial acetic acid and diethyl disulfide solution (the weight ratio of glacial acetic acid and diethyl disulfide solution is 5: 95) mix, prepare mixed solution, mixed solution and nitric acid solution pass into microreactor respectively after check valve respectively, the speed that mixed solution enters microreactor is 500L / hour, and the speed that nitric acid solution enters microreactor is 705L / hour, the gas mixture after passing through the microreactor enters the gas-liquid separator, and continues to stir and react for 2 hours at a constant temperature of 80°C in the gas-liquid separator to obtain a solution containing acetoallin, which is then discharged into the liquid separation tank. After layering, the oil phase and the water phase are separated, the concentration of acetoallin in the oil phase is detected and the yield of acetoallin is...

Embodiment 2

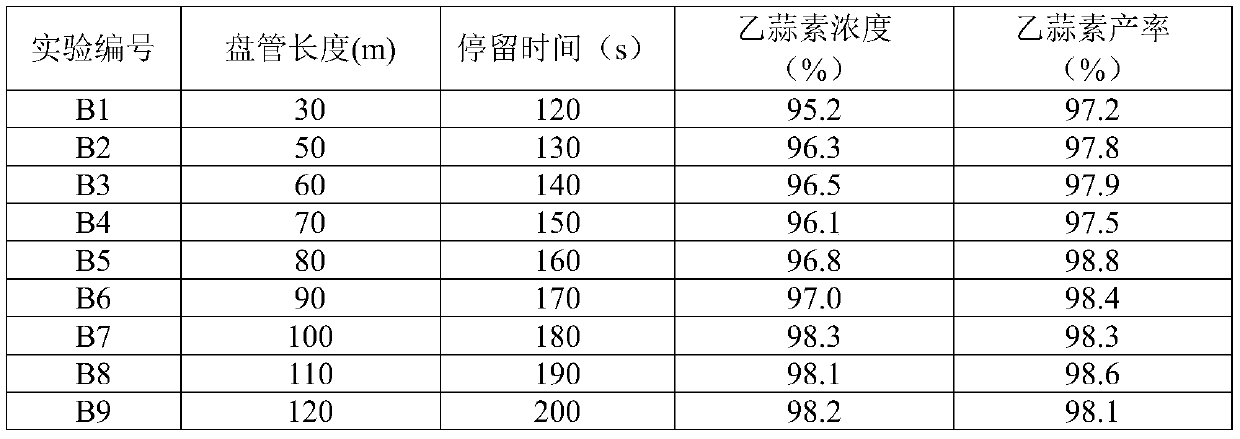

[0046] Embodiment 2 carries out pipeline reaction by the gas-liquid mixing that microreactor obtains

[0047] Raw material is that the concentration is 85% diethyl disulfide solution, glacial acetic acid and 45% nitric acid solution, glacial acetic acid and diethyl disulfide solution (the weight ratio of glacial acetic acid and diethyl disulfide solution is 5: 95) mix, prepare mixed solution, mixed solution and nitric acid solution pass into microreactor respectively after passing through check valve and pressurizing device respectively, the speed that mixed solution enters microreactor is 500L / hour, and nitric acid solution enters microreactor The speed of the device is 710L / hour, the gas mixture after passing through the microreactor is carried out to the gas-liquid separator, and the liquid after the gas-liquid separation is passed into the coil (nominal diameter Dn=20) for tubular reaction, and the coil is cooled to 55 ℃ and maintain a constant temperature, enter the gas-...

Embodiment 3

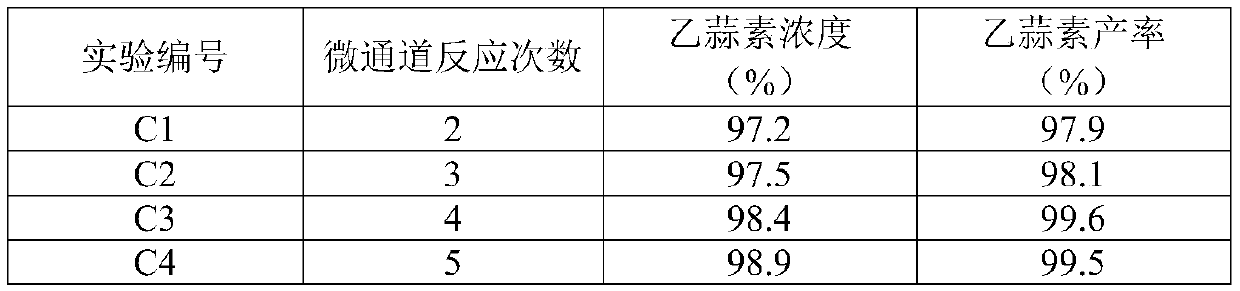

[0051] The gas-liquid mixing that embodiment 3 obtains by microreactor carries out microchannel reaction again

[0052] (1) 2 microchannel reactions

[0053] Raw material is that the concentration is 85% diethyl disulfide solution, glacial acetic acid and 45% nitric acid solution, glacial acetic acid and diethyl disulfide solution (the weight ratio of glacial acetic acid and diethyl disulfide solution is 5: 95) mix, prepare mixed solution, mixed solution and nitric acid solution respectively pass into microreactor (the microreactor of experiment number A3) (the 1st microchannel reaction) after check valve and pressurizing device respectively, mix The speed at which the solution enters the microreactor is 500L / hour, and the speed at which the nitric acid solution enters the microreactor is 497L / hour (70% of the total amount of nitric acid). The final liquid is passed into the microreactor (the microreactor of the experiment number A3), and the nitric acid solution is added at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com