Preparation process of novel bismuth temperature-resistant environment-friendly pigment

An environmentally friendly pigment and preparation process technology, applied in inorganic pigment processing, fibrous fillers, chemical instruments and methods, etc., can solve the problems of complex process, high cost, slow reaction rate, etc., achieve scientific and reasonable structure, safe and convenient use, colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

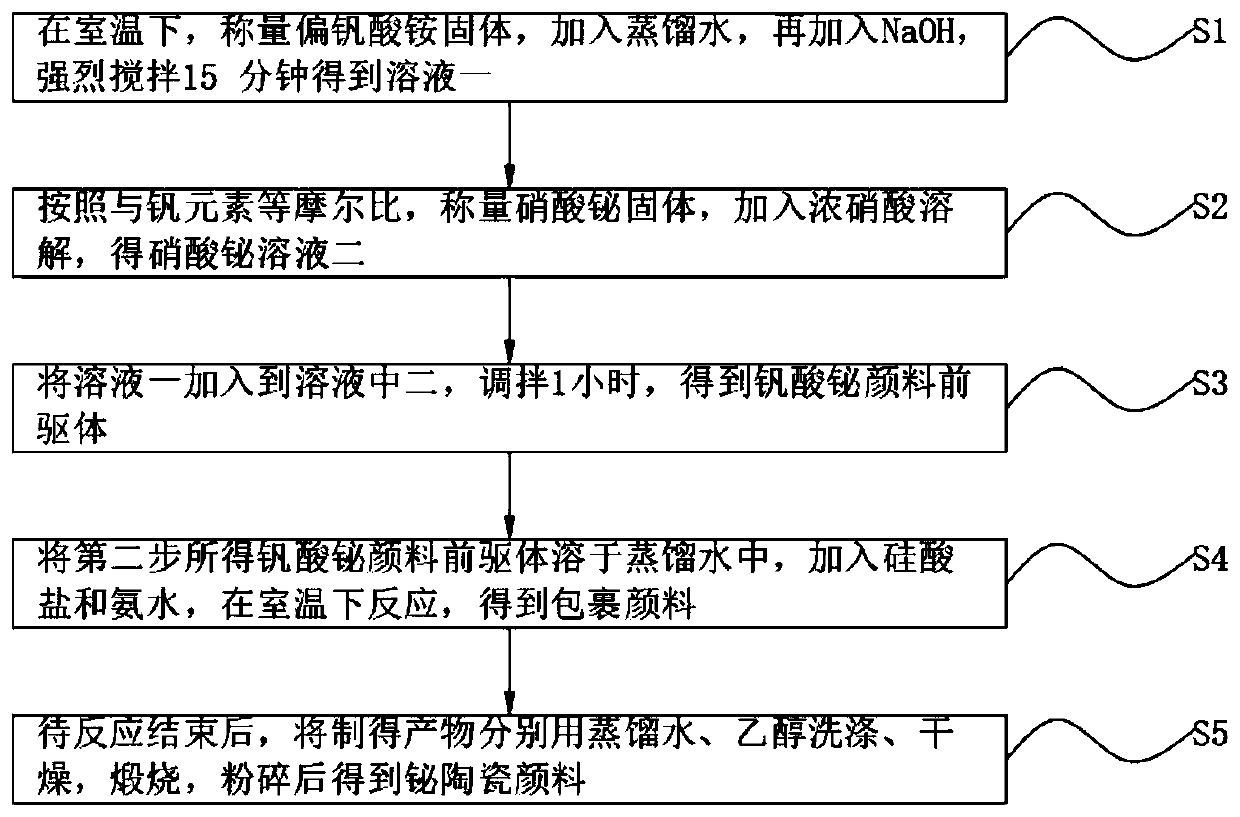

[0036] Embodiment 1: as Figure 1-3 As shown, the present invention provides technical scheme, the preparation technology of a kind of bismuth heat-resistant novel environment-friendly pigment, comprises the steps:

[0037] S1. At room temperature, weigh the ammonium metavanadate solid, add distilled water, then add NaOH, and stir vigorously for 15 minutes to obtain solution 1;

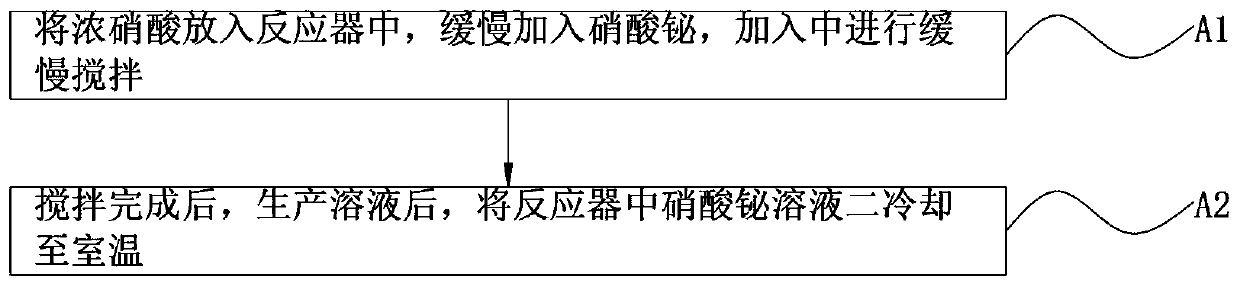

[0038] S2, according to equimolar ratio with vanadium element, weigh bismuth nitrate solid, add concentrated nitric acid to dissolve, obtain bismuth nitrate solution 2;

[0039] S3, adding solution 1 to solution 2, and mixing for 1 hour to obtain a bismuth vanadate pigment precursor;

[0040] S4, dissolving the bismuth vanadate pigment precursor obtained in the second step in distilled water, adding silicate and ammonia water, and reacting at room temperature to obtain a coated pigment;

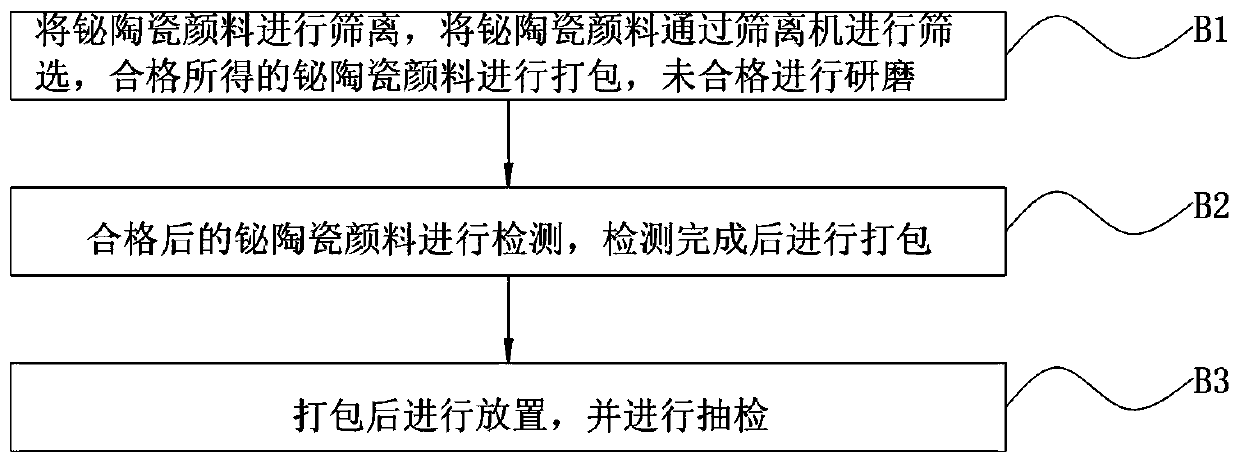

[0041] S5. After the reaction is completed, the obtained product is washed with distilled water and ethanol, dri...

Embodiment 2

[0060] Embodiment 2: as Figure 1-3 As shown, the present invention provides technical scheme, the preparation technology of a kind of bismuth heat-resistant novel environment-friendly pigment, comprises the steps:

[0061] S1. At room temperature, weigh the ammonium metavanadate solid, add distilled water, then add NaOH, and stir vigorously for 15 minutes to obtain solution 1;

[0062] S2, according to equimolar ratio with vanadium element, weigh bismuth nitrate solid, add concentrated nitric acid to dissolve, obtain bismuth nitrate solution 2;

[0063] S3, adding solution 1 to solution 2, and mixing for 1 hour to obtain a bismuth vanadate pigment precursor;

[0064]S4, dissolving the bismuth vanadate pigment precursor obtained in the second step in distilled water, adding silicate and ammonia water, and reacting at room temperature to obtain a coated pigment;

[0065] S5. After the reaction is completed, the obtained product is washed with distilled water and ethanol, drie...

Embodiment 3

[0084] Embodiment 3: as Figure 1-3 As shown, the present invention provides technical scheme, the preparation technology of a kind of bismuth heat-resistant novel environment-friendly pigment, comprises the steps:

[0085] S1. At room temperature, weigh the ammonium metavanadate solid, add distilled water, then add NaOH, and stir vigorously for 15 minutes to obtain solution 1;

[0086] S2, according to equimolar ratio with vanadium element, weigh bismuth nitrate solid, add concentrated nitric acid to dissolve, obtain bismuth nitrate solution 2;

[0087] S3, adding solution 1 to solution 2, and mixing for 1 hour to obtain a bismuth vanadate pigment precursor;

[0088] S4, dissolving the bismuth vanadate pigment precursor obtained in the second step in distilled water, adding silicate and ammonia water, and reacting at room temperature to obtain a coated pigment;

[0089] S5. After the reaction is completed, the obtained product is washed with distilled water and ethanol, dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com