Process for selectively recovering lithium in waste lithium iron phosphate battery by means of mechanochemical activation method

A lithium iron phosphate battery, mechanochemical technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of cumbersome process, secondary pollution, slow process, etc., achieve low reaction temperature, and realize reuse , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

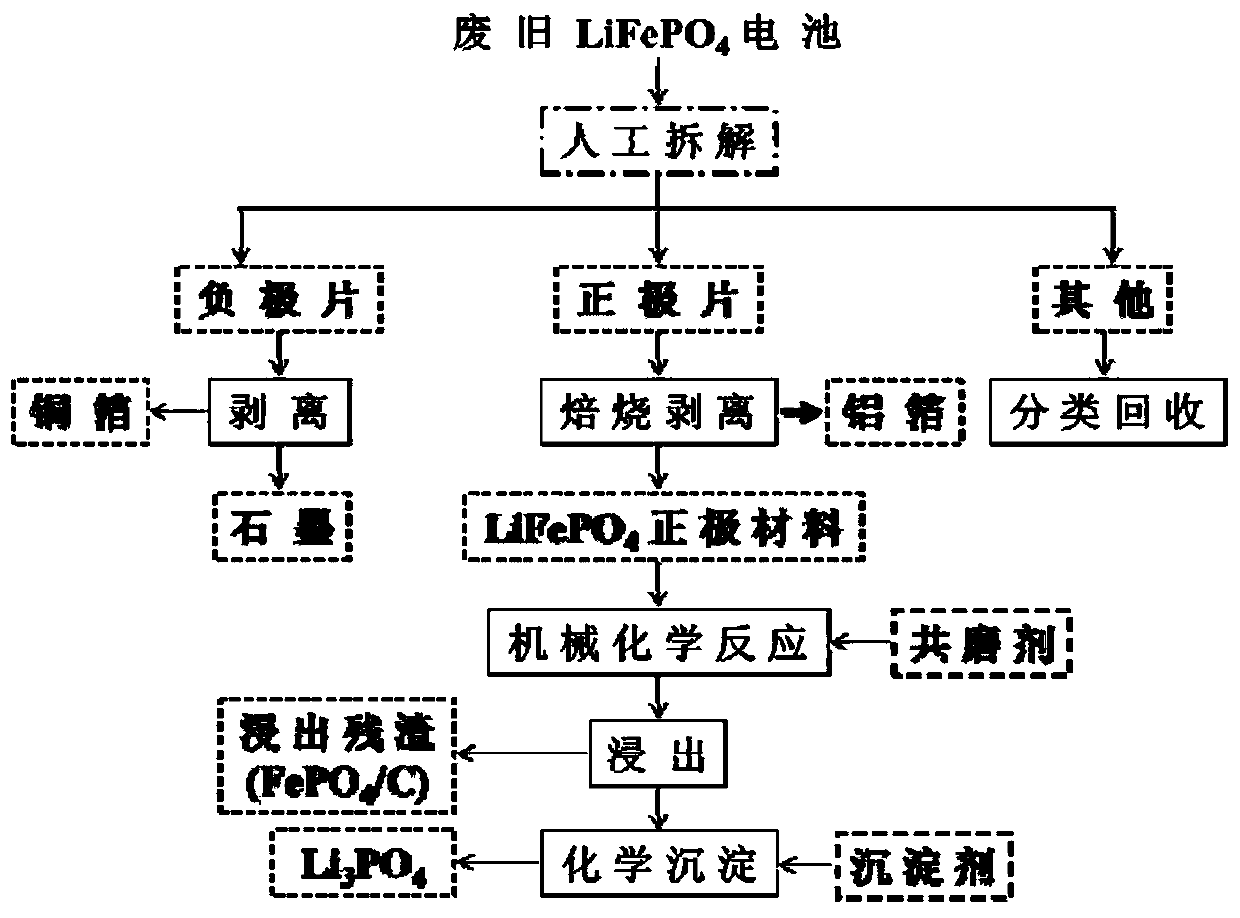

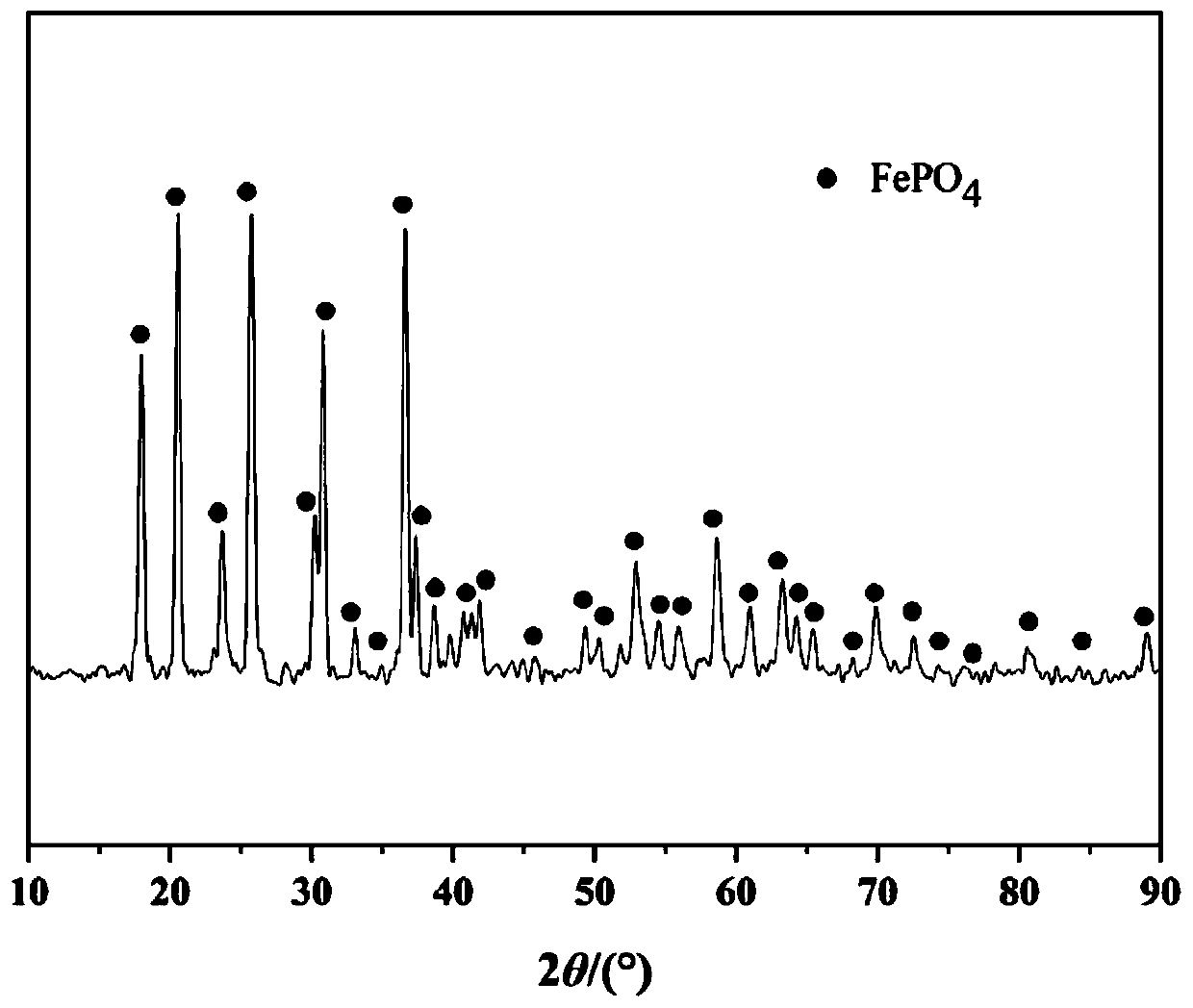

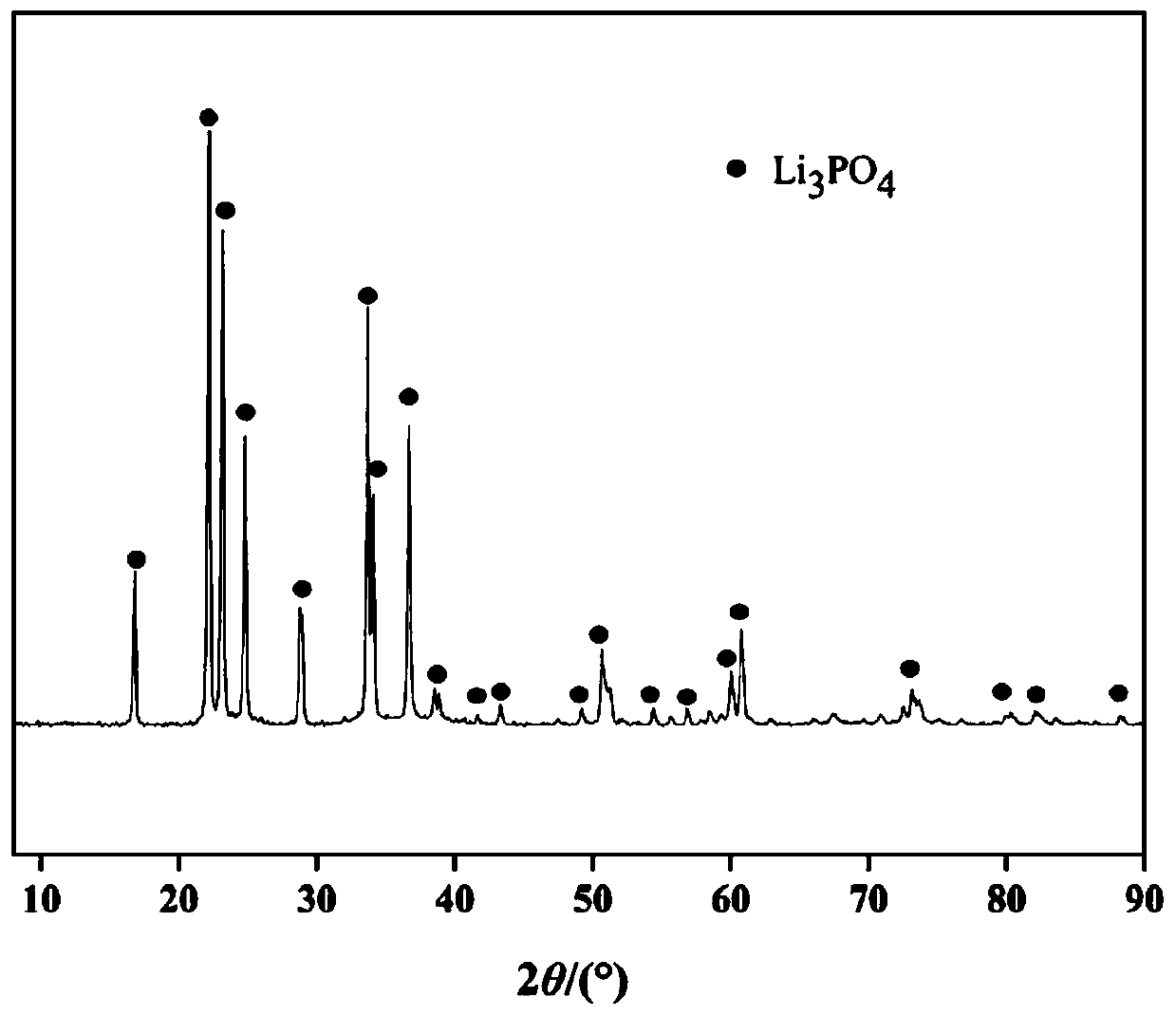

[0022] according to figure 1 Flowchart, the positive electrode sheet is collected after the waste lithium iron phosphate battery is discharged, and the positive electrode sheet is cut into 4*2cm small strips with scissors, placed in a tube furnace under a nitrogen atmosphere at 360°C for 2 hours, and then taken out to obtain aluminum foil and positive electrode materials; With cathode material LiFePO 4 As a raw material, add an appropriate amount of water and a stoichiometric co-grinding agent for mechanochemical activation treatment, grind at a speed of 600rpm for 30min, then transfer to a round-bottomed Erlenmeyer flask, add 4vol.% leaching agent solution, and carry out solidification after leaching for 60min. Liquid separation and collection of leaching liquid and leaching residue ( figure 2 ); the leaching solution was evaporated at 105°C for several hours, and the remaining appropriate amount of lithium-containing solution was moved to a water bath with a water temperat...

Embodiment 2

[0024] according to figure 1 Flowchart, the positive electrode sheet is collected after the waste lithium iron phosphate battery is discharged, and the positive electrode sheet is cut into 4*2cm small strips with scissors, placed in a tube furnace under a nitrogen atmosphere at 360°C for 2 hours, and then taken out to obtain aluminum foil and positive electrode materials; With cathode material LiFePO 4 As a raw material, add an appropriate amount of water and a stoichiometric compound co-grinding agent for mechanochemical activation treatment, wherein the molar ratio of lithium iron phosphate to co-grinding agent is 1:0.5:0.5, grind at 600rpm for 30min and then transfer to a circular Bottom Erlenmeyer flask, add 4vol.% leaching agent solution, leaching for 60 minutes, then carry out solid-liquid separation to collect the leaching solution and leaching residue; the leaching solution evaporates water at 105°C for a few hours, and the remaining appropriate amount of lithium-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com