Heat preservation water tank for improving cold starting performance of engine

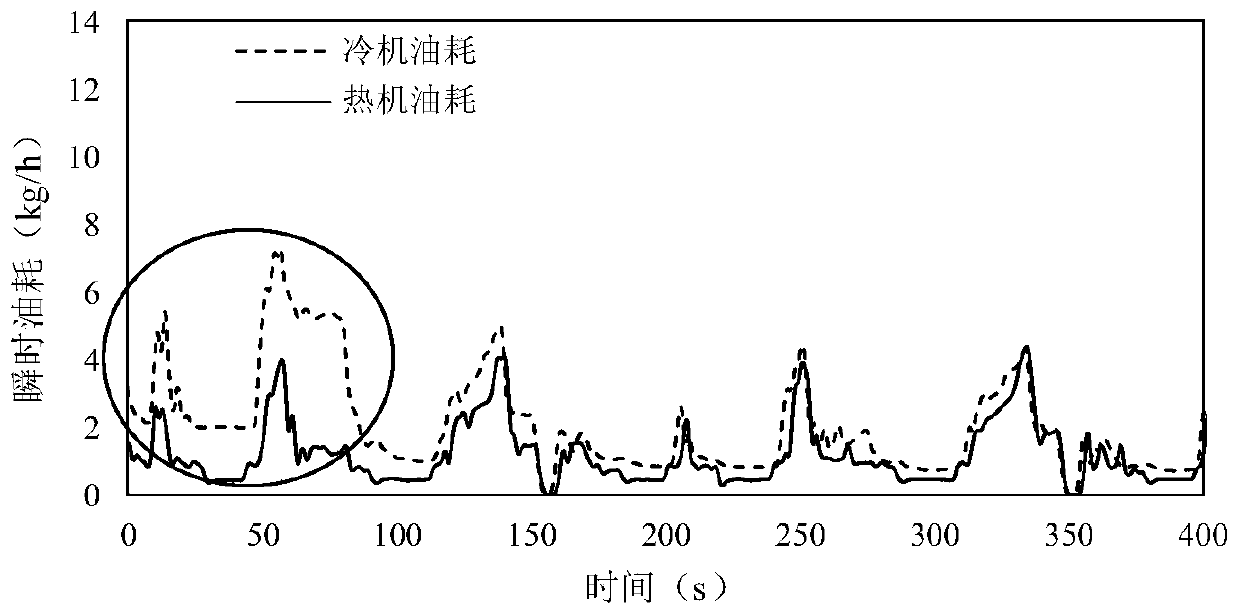

A heat preservation water tank and engine technology, applied in the direction of engine starting, engine cooling, engine components, etc., can solve the problems of reduced effective thermal efficiency, poor lubrication effect, and deterioration of combustion, so as to avoid excessive temperature and cold start work condition, the effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-5 The technical solution of the present invention is described in detail.

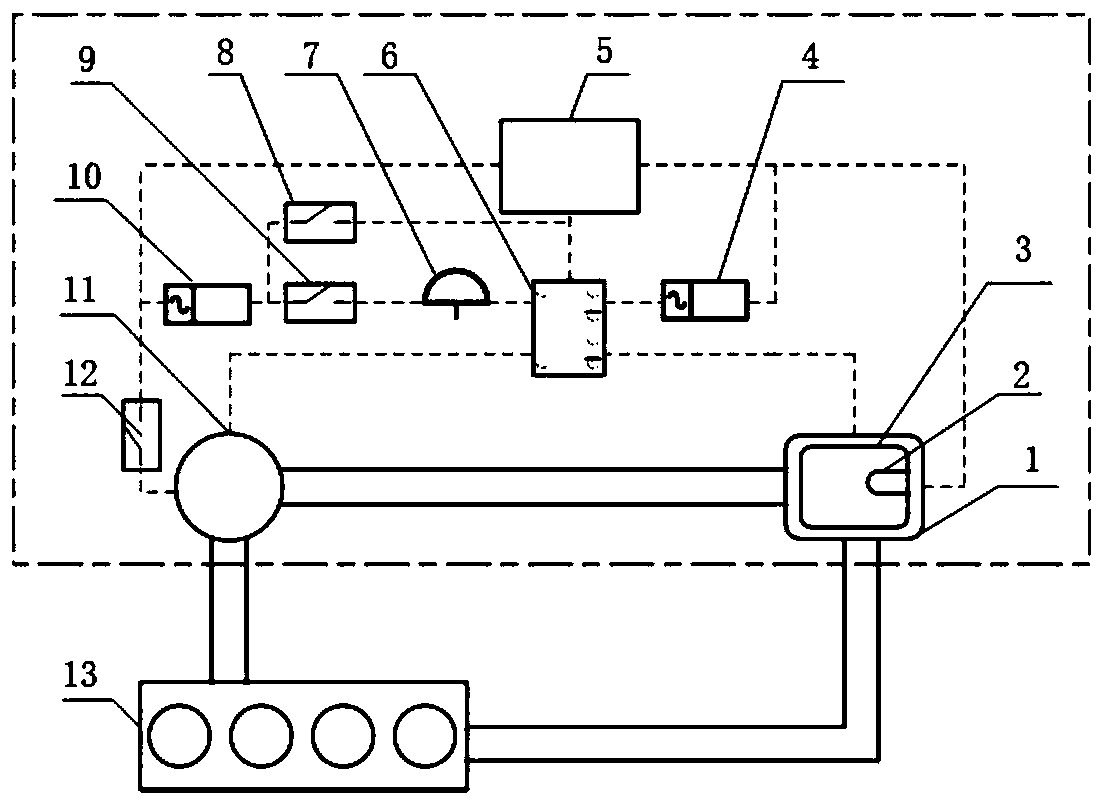

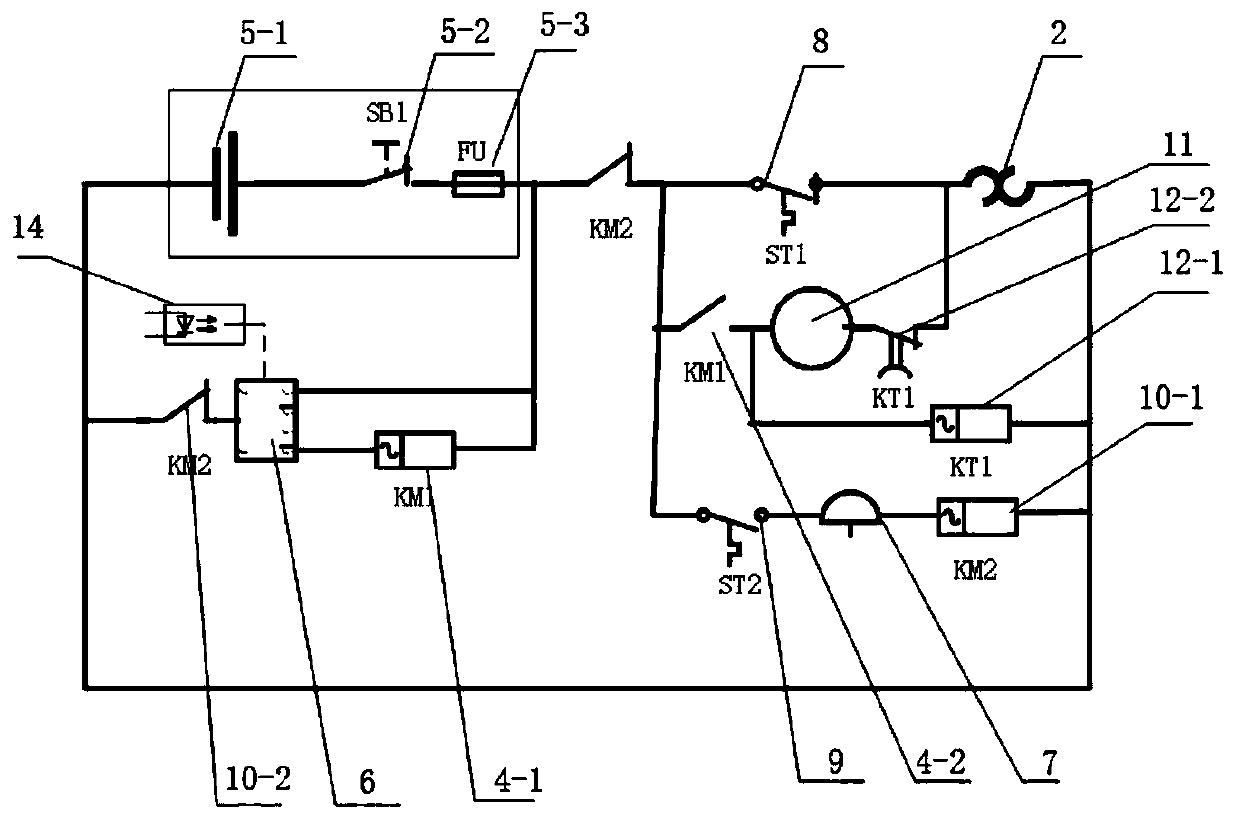

[0039] Such as figure 1As shown, this embodiment provides a heat preservation water tank for improving engine cold start performance, comprising: heat preservation material layer 1, heating element 2, water tank 3, relay KM14, power supply device 5, controller 6, alarm 7, temperature control Switch ST18, temperature control switch ST29, relay KM210, water pump 11, time relay 12, engine 13, remote control transmitter 14.

[0040] The insulation material layer 1 adopts common insulation materials such as polyurethane foam, polystyrene, and PEF for insulation. The insulation material layer 1 is wrapped around the periphery of the water tank 3 to reduce the heat loss caused by the water tank and the environment.

[0041] The heating element 2 is bolted to the wall of the water tank and placed horizontally at the bottom of the water tank at about a quarter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com