Co-N doped porous carbon coated carbon nanotube core-shell structure catalyst and preparation method thereof and application of Co-N doped porous carbon coated carbon nanotube core-shell structure catalyst

A core-shell structure, porous carbon technology, applied in structural parts, electrical components, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

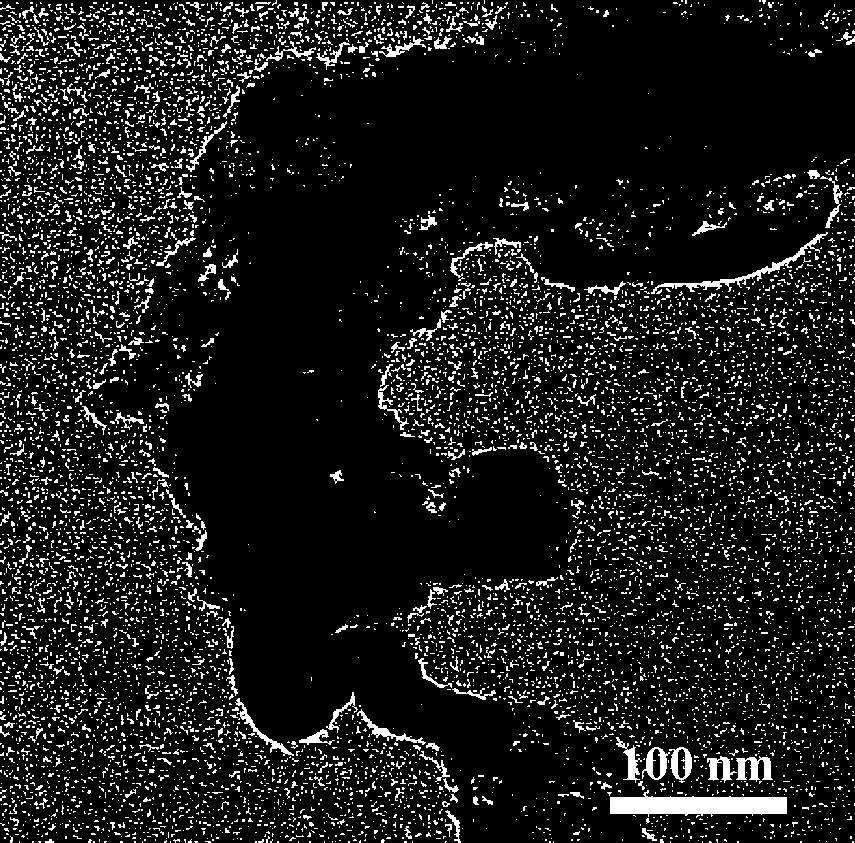

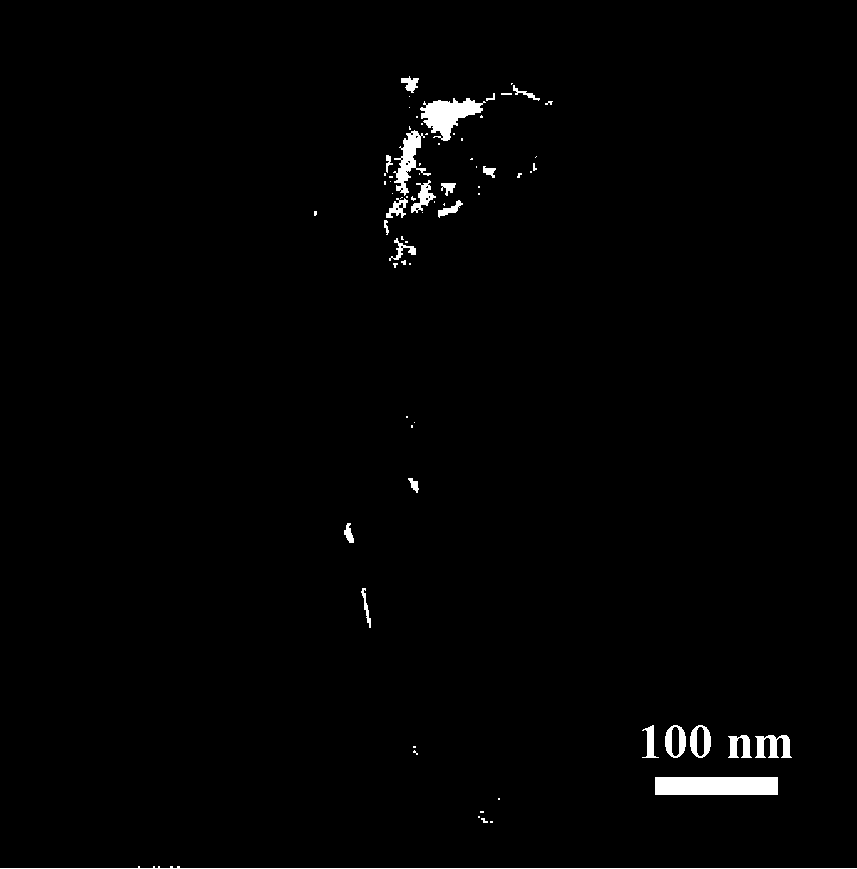

Image

Examples

Embodiment

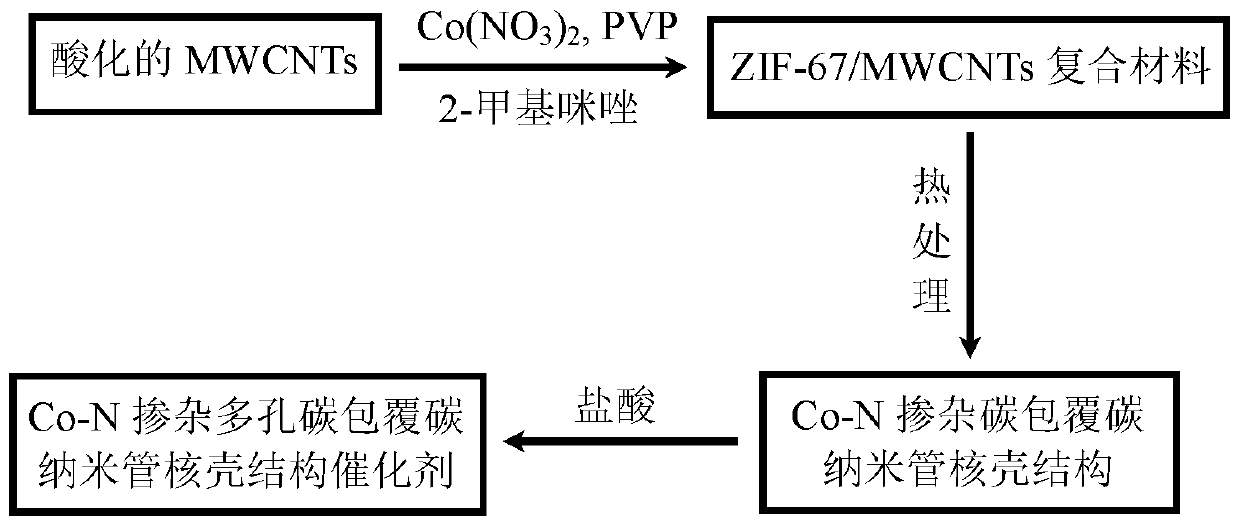

[0025] refer to figure 1 , a method for preparing a Co-N doped porous carbon-coated carbon nanotube core-shell structure catalyst, comprising the steps of:

[0026] 1) Add 4 mg of acidified MWCNTs (AO-MWCNTs) and 40-150 mg of PVP into a container containing 5 mL of methanol, and add 291 mg of Co(NO 3 ) 2 ·6H 2 O, continue to sonicate for 2 h and then centrifuge, add the sample separated by centrifugation into a container containing 10 mL of methanol, and add 10 mL of methanol solution of 2-methylimidazole after ultrasonic dispersion, in which, 2-methylimidazole 3-19 mmol, after standing for 12 h, centrifuge and dry to obtain ZIF-67 / MWCNTs composite material;

[0027] 2) Weigh 50 mg of the ZIF-67 / MWCNTs composite sample obtained in step 1), place it in a quartz tube furnace and heat-treat it at 500-1000°C for 3 h in an Ar atmosphere to obtain Co-N doped carbon-coated carbon The nanotube core-shell structure is CNTs@Co-N-C;

[0028] 3) Add 30 mg of CNTs@Co-N-C obtained in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com