A system and method for estimating the rotor position and speed of a permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor position technology, applied in the estimation/correction of motor parameters, control systems, electronic commutators, etc., can solve problems such as the phase delay of the low-pass filter of the observer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

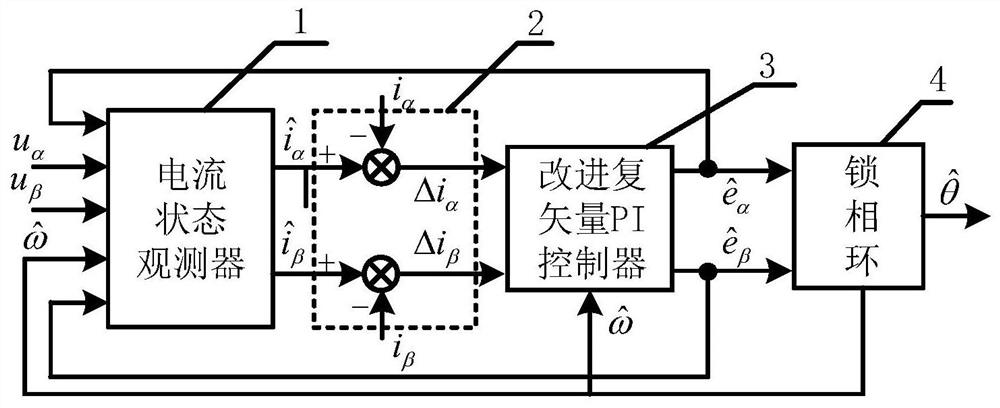

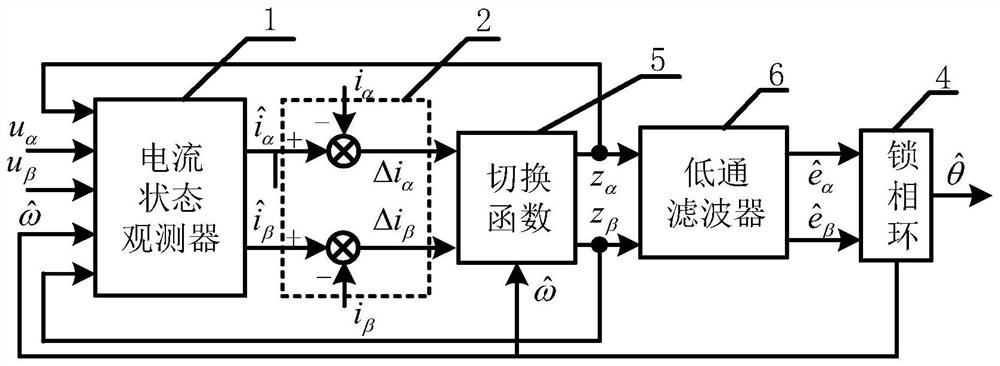

[0041] A permanent magnet synchronous motor rotor position and speed estimation system using an improved sliding mode observer, such as figure 1 As shown, the technical solutions adopted are as follows:

[0042] The system adopts a sliding mode observer, and the sliding mode observer includes a current state observer 1, a comparator 2, an improved complex vector PI controller 3 and a phase-locked loop 4; the signal output terminal of the current state observer 1 Be connected with the signal input end of described comparator 2; The signal output end of described comparator 2 is connected with the signal input end of described improved complex vector PI controller 3; The signal output end of described improved complex vector PI controller 3 It is connected with the signal input end of the phase-locked loop 4; the feedback signal output end of the improved complex vector PI controller 3 is connected with the feedback signal input end of the current state observer 1 . The input o...

Embodiment 2

[0057] A method for estimating the rotor position and speed of a permanent magnet synchronous motor using an improved sliding mode observer, the method for estimating the rotor position and speed of a permanent magnet synchronous motor includes:

[0058] Step 1: The voltages of the α and β axes of the permanent magnet synchronous motor are input into the current state observer, and the current observation values of the α and β axes are obtained through the processing of the current state observer

[0059] Step 2: The current observation values of the α and β axes The input is to the comparator, where the current observations of the α and β axes are combined by and the α and β axis current detection values of the α and β axes i α i β Compare and obtain the α and β axis current deviation Δi α , Δi β ;

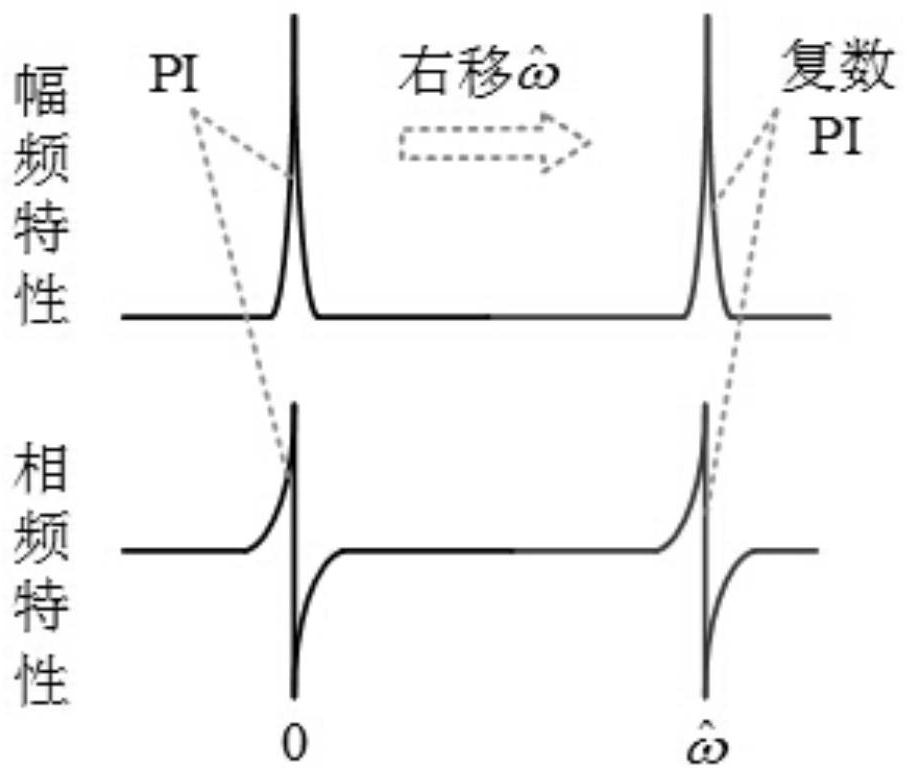

[0060] Step 3: The α and β axis current deviation Δi α , Δi β Input into the improved complex vector PI controller; make the current deviation Δi α , Δi β Mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com