Manufacture method for easy-to-lay, drought-resistant and slope-protecting vegetation blankets

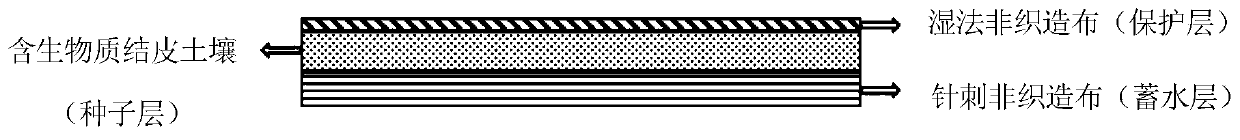

A technology for vegetation blankets and slope protection is applied in the field of preparation of easy-to-lay drought-resistant slope protection vegetation blankets, which can solve the problems of inability to lay vegetation blankets in depth, space limitations, etc., and achieve the effects of fast water loss, easy transportation, and prevention of water evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of the present invention is easy to lay drought-resistant slope protection type vegetation blanket, specifically comprises the following steps:

[0026] Step 1, get 80-120g dry waste cotton fiber, the jute fiber after 20-80g degumming, cut into average 8mm length respectively, it is mixed with 4-6gNa 2 CO 3 , 5-7gH 2 o 2 Mix with 5-30g of special additives, mix the raw materials with water (solid-liquid mass volume ratio is 1:8) and cook for 185min. Fully wash the cooked slurry, and then use a beater to beat the raw materials separately, control the beating degree of the slurry to 60°SR, and make a suspended slurry for later use. The configured suspension slurry is processed into a net, and the final square meter weight is (60-100) g / m 2 The surface layer is made of wet-laid nonwoven fabric;

[0027] Step 2. Collect and select well-developed biological crusts, use a small shovel to scoop out the crust layer with a thickness of 1-10mm on...

Embodiment 1

[0037] A kind of preparation method of the present invention is easy to lay drought-resistant slope protection type vegetation blanket, specifically comprises the following steps:

[0038] Step 1, get 100g dry waste cotton fiber, the jute fiber after 20g degumming, be cut into 8mm long respectively, with 4.5gNa 2 CO 3 , 6.0gH 2 o 2 Mix with 10g of special additives, mix the raw materials with water (solid-liquid mass volume ratio is 1:8) and cook for 185min. Fully wash the cooked slurry, and then use a beater to beat the raw materials separately, and control the beating degree of the slurry to 60°SR. After the preparation of waste cotton fiber raw materials is completed, the configured slurry is processed into a net, and the final square meter weight is 60g / m 2 The surface layer is made of wet-laid nonwoven fabric;

[0039] Step 2. Collect and select well-developed biological crusts, use a small shovel to scoop out the crust layer with a thickness of 1mm on the surface, b...

Embodiment 2

[0043] A kind of preparation method of the present invention is easy to lay drought-resistant slope protection type vegetation blanket, specifically comprises the following steps:

[0044] Step 1, get 80g dry waste cotton fiber, the jute fiber after 60g degumming, be cut into 8mm long respectively, with 4.5gNa 2 CO 3 , 6.0gH 2 o 2 Mix with 15g of special additives, mix the raw materials with water (solid-liquid mass volume ratio is 1:8) and cook for 185min. Fully wash the cooked slurry, and then use a beater to beat the raw materials separately, and control the beating degree of the slurry to 60°SR. After the preparation of waste cotton fiber raw materials is completed, the configured slurry is processed into a net, and the final square meter weight is 80g / m 2 The surface layer is made of wet-laid nonwoven fabric;

[0045] Step 2. Collect and select well-developed biological crusts, use a small shovel to scoop out the crust layer with a thickness of 1-10mm on the surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com