Full-automatic meatball forming assembly line and control method thereof

A fully automatic, assembly-line technology, applied in meat processing, slaughtering, food science, etc., can solve problems such as affecting the quality of meatballs, long production line length, and large footprint, avoiding loose meat, high production efficiency, and saving floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

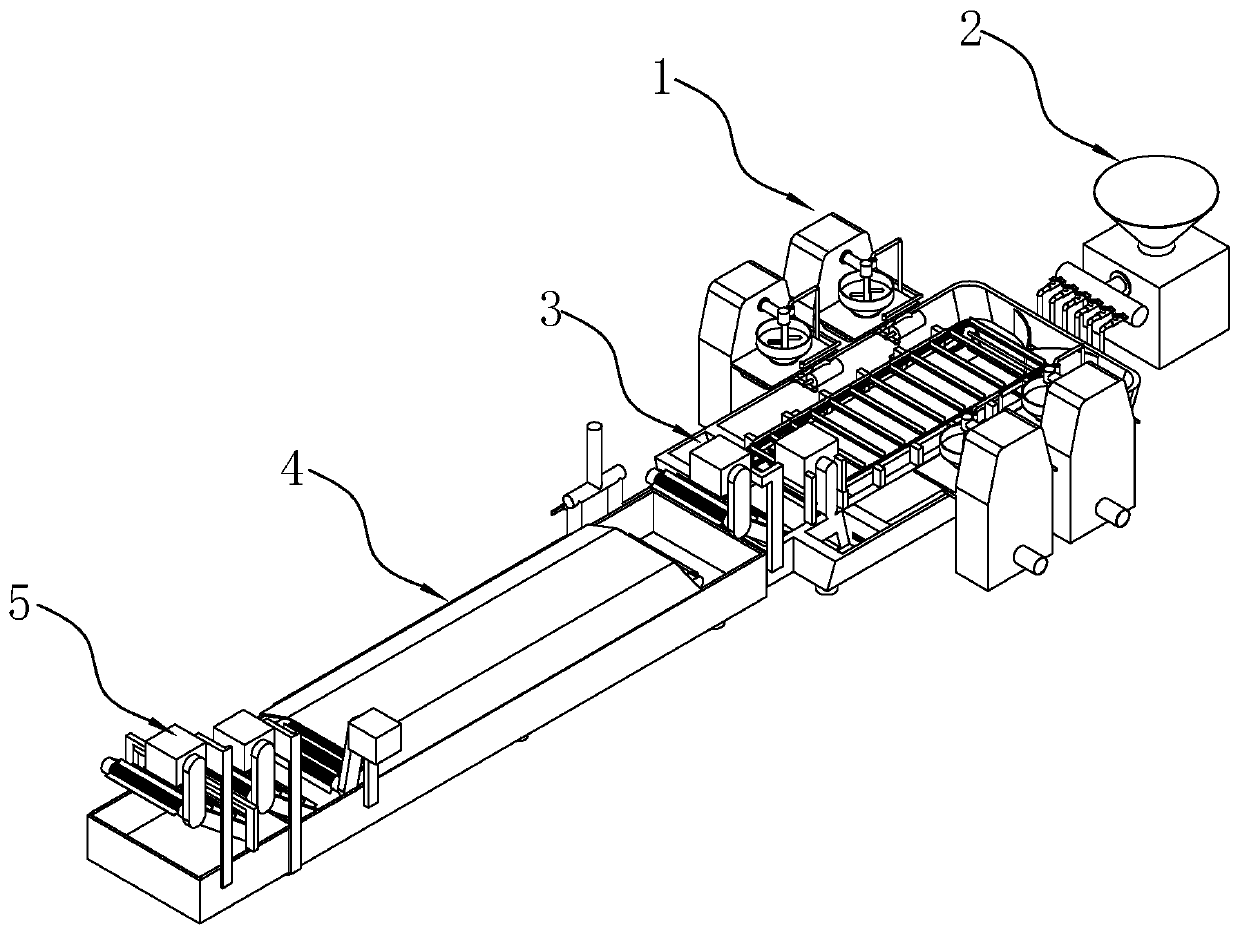

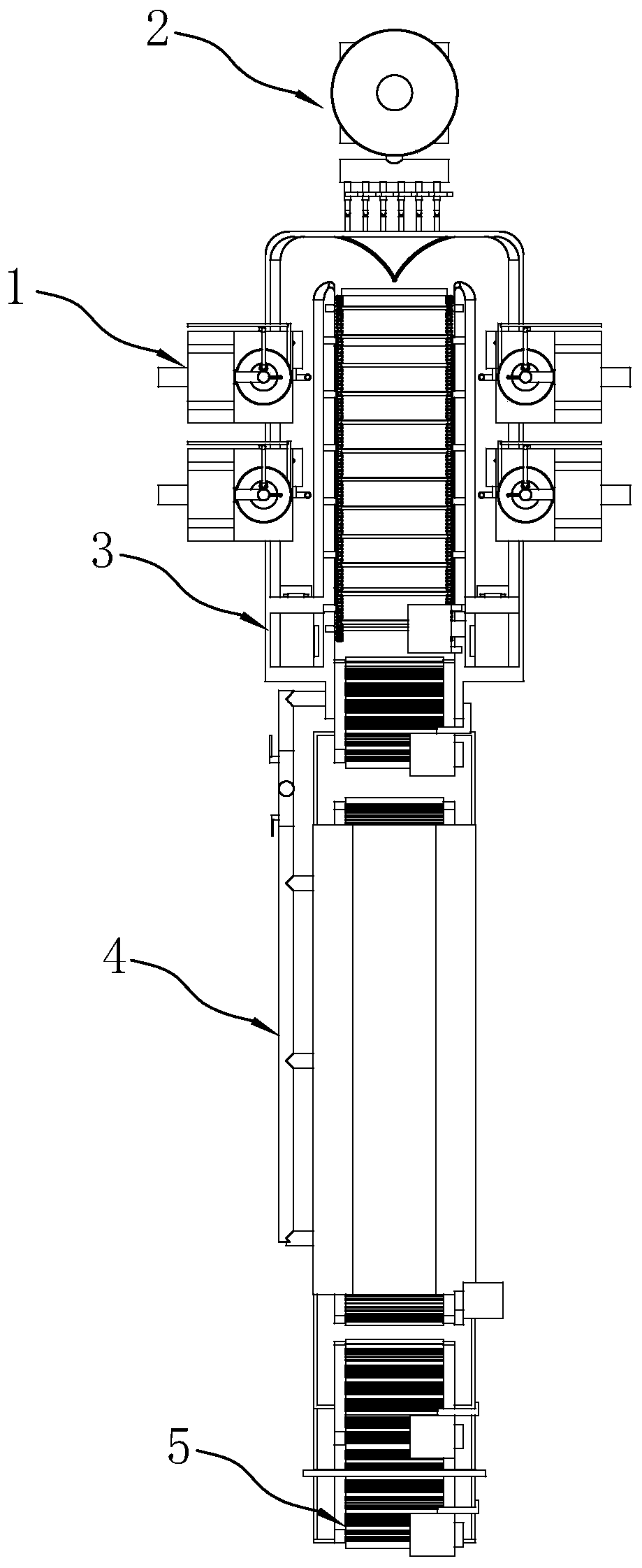

[0030] As shown in the figure, the fully automatic meatball forming line of the present invention includes: a meatball forming machine 1, a splitter 2, a setting machine 3, a high-temperature cooking machine 4 and a water spraying and degreasing machine 5.

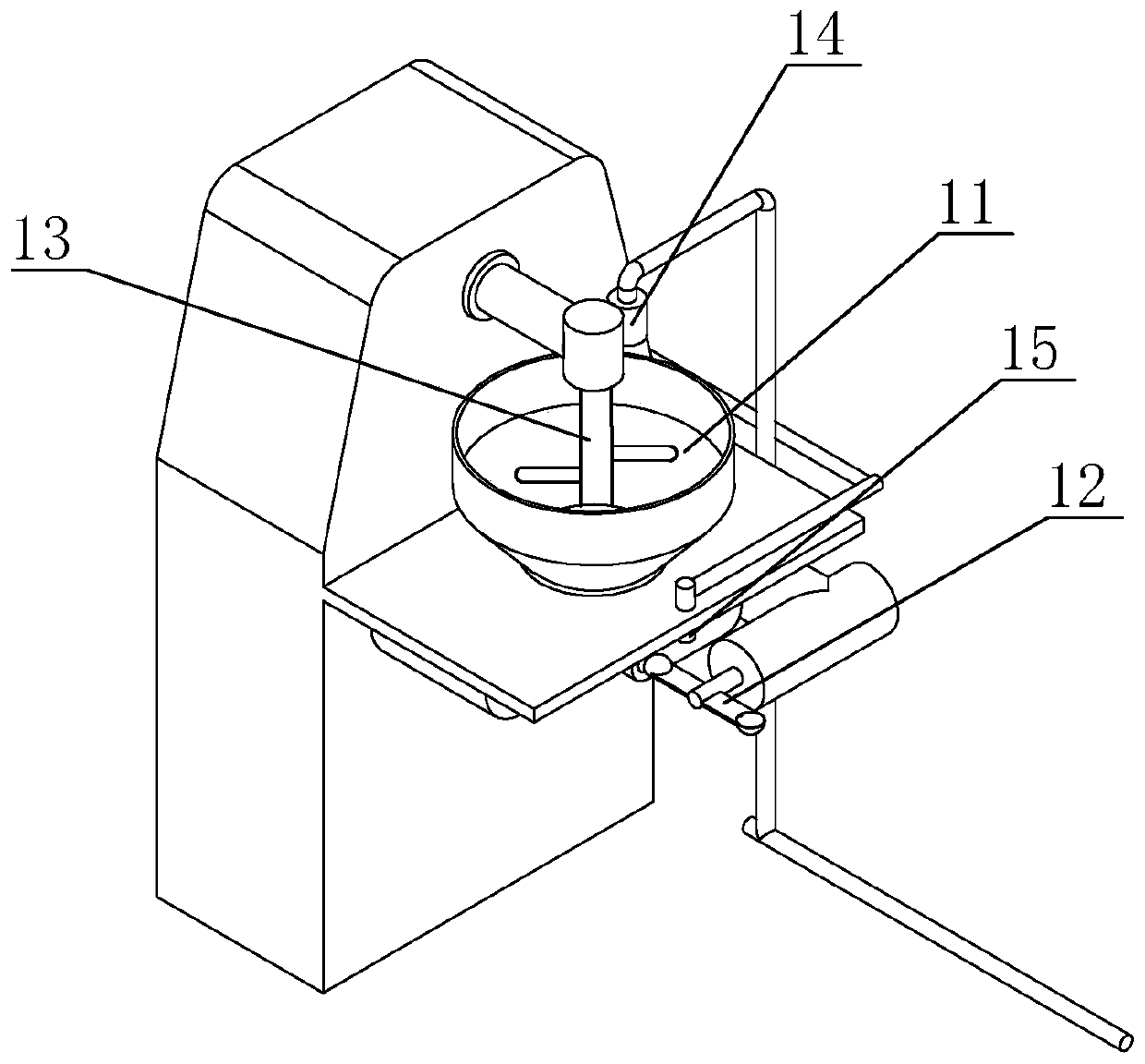

[0031] The meatball forming machine 1 comprises a forming hopper 11, which is communicated with the forming hopper 11 and is used to convey the forming auger (not shown in the figure) for conveying the meat slurry, and is located at the discharge end of the forming auger for separating the meatballs. Separator 12, forming hopper 11 is provided with a stirring shaft 13, the stirring shaft 13 is provided with stirring blades, the top of the forming hopper 11 is provided with a meat slurry outlet 14, the meat slurry is stirred by the stirring shaft 13 in the hopper to avoid condensation, and the forming twist The dragon is driven by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com