Diamond composite milling cutter for oil spray nozzle mounting hole

A technology of diamond and mounting holes, which is applied in the direction of cutting tools, milling cutters, and milling machine equipment for milling machines. It can solve problems such as increasing the uncertainty of unbalanced quantities, unbalanced variables of tools, and increased tool wear, so as to avoid repeated movements. Balance measurement and unbalance removal, ensure dynamic balance accuracy, and smooth chip removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

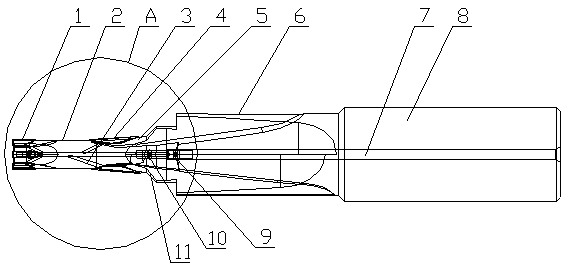

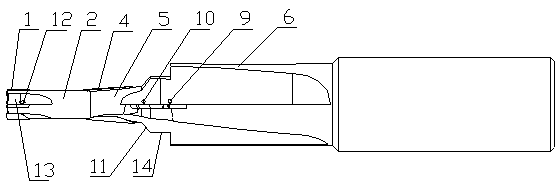

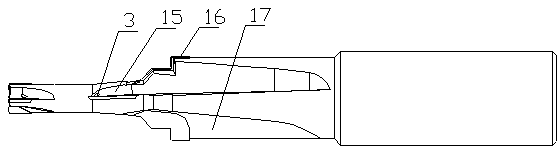

[0021] A diamond composite milling cutter for the installation hole of an oil injector, comprising a cutter body and a handle 8, the cutter body and the handle 8 are coaxially fixedly connected, and the diameter of the cutter body is successively increased from the front to the back of the primary cutting section 2, the secondary The cutting section 5 and the third-level cutting section are composed of the first-level cutting section 2 and the third-level cutting section as a whole, and the second-level cutting section 5 is in the shape of a cone (conical column) whose diameter gradually increases from front to back. The first-level cutting section 2, the second-level cutting section 5 and the third-level cutting section are coaxially connected. Same diameter. There are four cutting teeth in the circumferential direction of the first-level cutting section 2, two cutting teeth in the circumferential direction of the second-level cutting section 5, and two cutting teeth in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com