Glue removing agent and applications of glue removing agent in rail transit vehicle window maintenance

A glue and solvent technology, applied in the directions of detergent compounding agent, detergent composition, detergent composition solvent, etc., can solve the problems of long degumming time and poor degumming effect, so as to speed up the degumming rate and reduce Adhesion, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

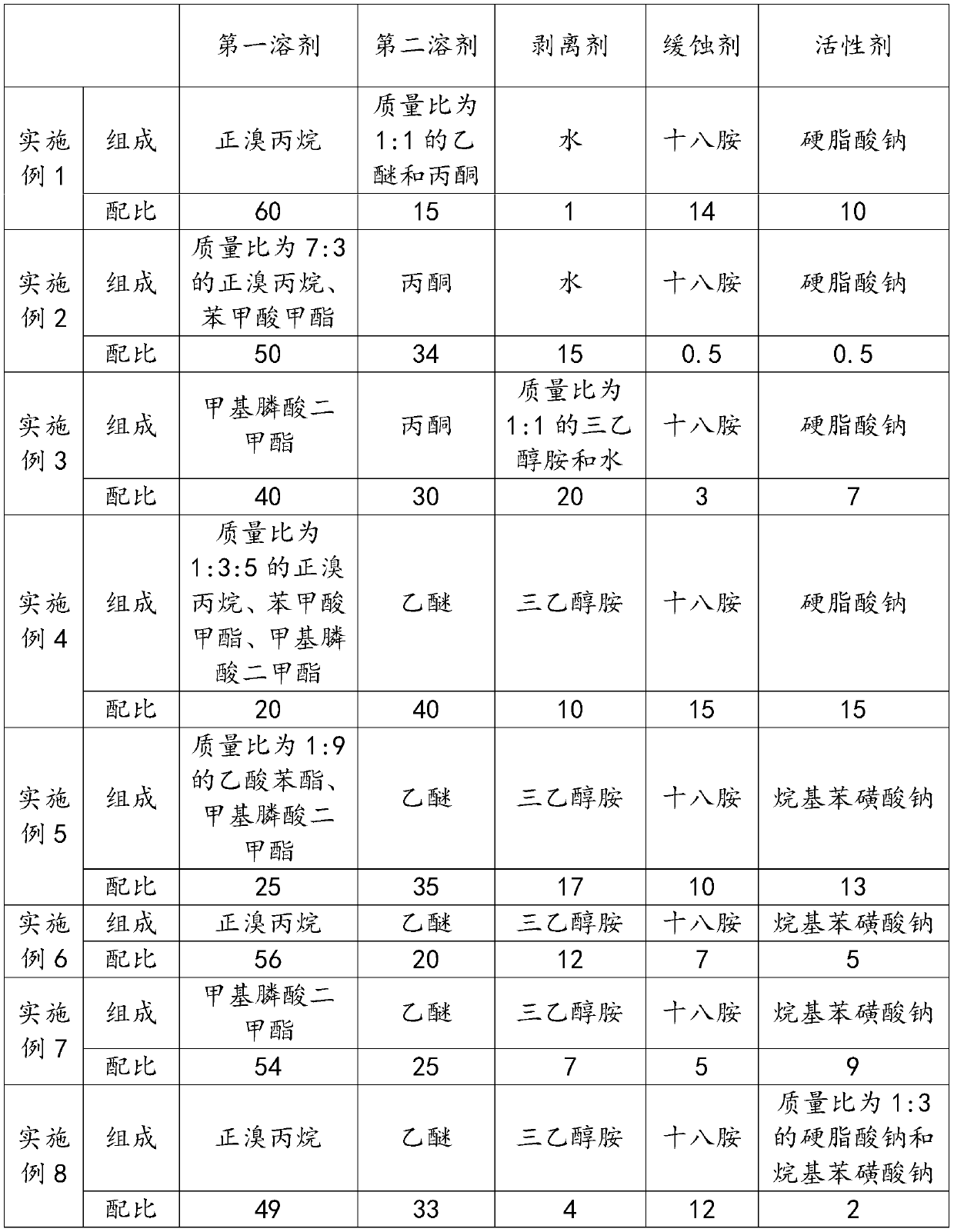

[0027] A glue remover, comprising: a first solvent, a second solvent, a stripping agent, a corrosion inhibitor, and an active agent.

[0028] Wherein, the first solvent is one or more random ratio mixtures in n-bromopropane, methyl benzoate, phenyl acetate, dimethyl methylphosphonate; the second solvent is ether or / and acetone; stripping agent It is triethanolamine or / and water; the corrosion inhibitor is octadecylamine; the active agent is sodium alkylbenzene sulfonate or / and sodium stearate.

[0029] In the present invention, the specific composition and proportioning ratio of each substance are shown in Table 1, and the weight unit of each component in Table 1 is Kg.

[0030] Table 1

[0031]

[0032] After the various components are mixed in the present invention, the adhesive remover prepared by mixing is non-flammable and explosive, therefore, the present invention has non-flammable and explosive properties. At the same time, by using the finished products of Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com