Monocrystal high-temperature alloy component with high defect tolerance and preparation method thereof

A technology for superalloys and components, applied in the direction of single crystal growth, single crystal growth, metal processing equipment, etc., can solve problems such as difficulty in preparing large-sized internal micropores and small-angle grain boundaries, affecting the performance of aerodynamics, and small tolerances , to achieve the effect of improving the purity, increasing the critical value, and optimizing the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

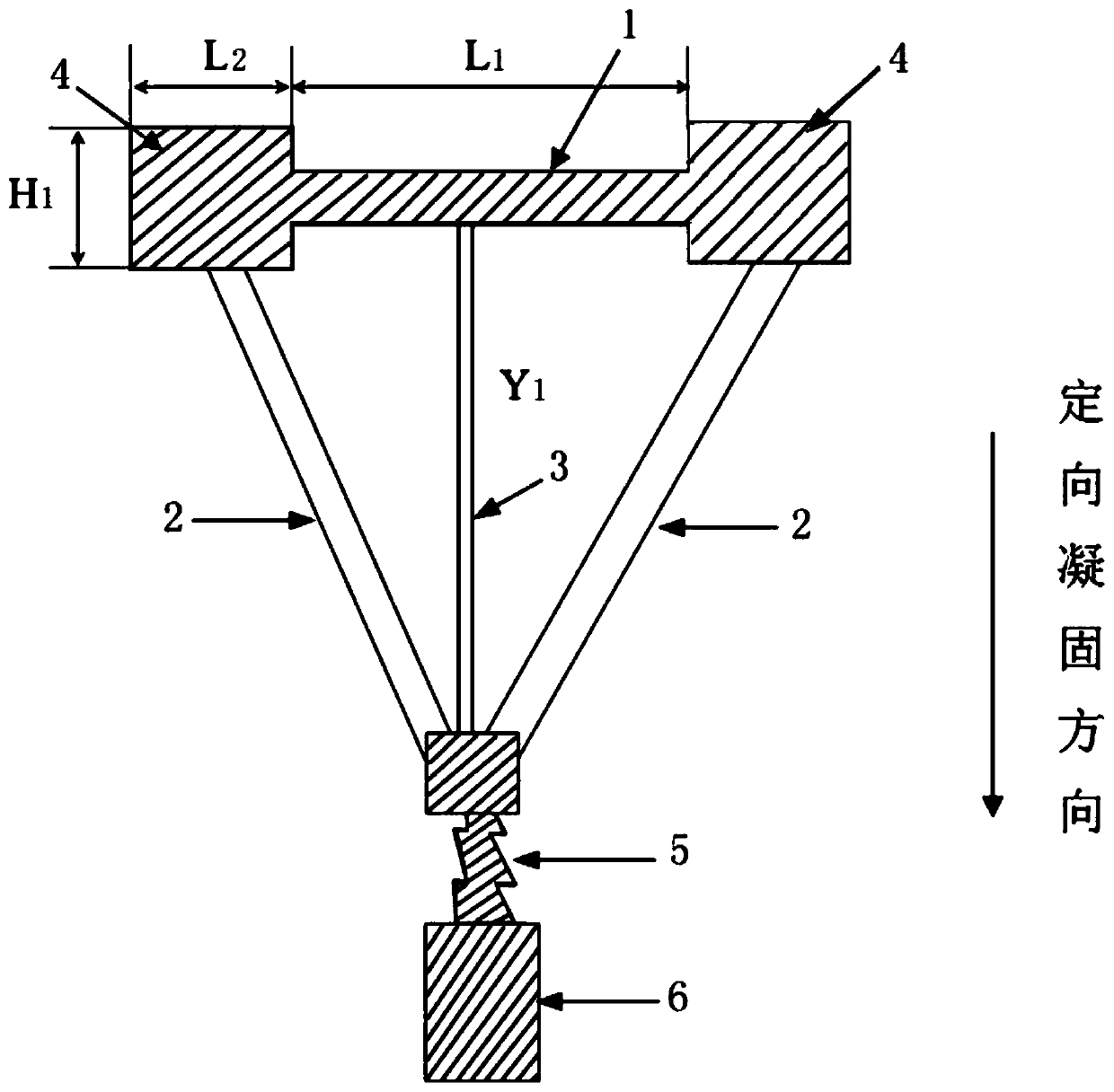

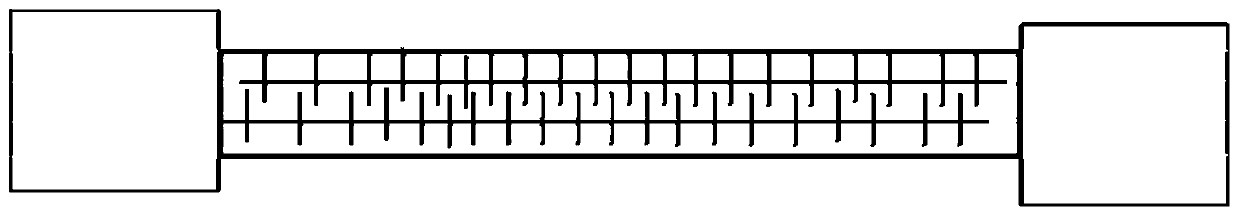

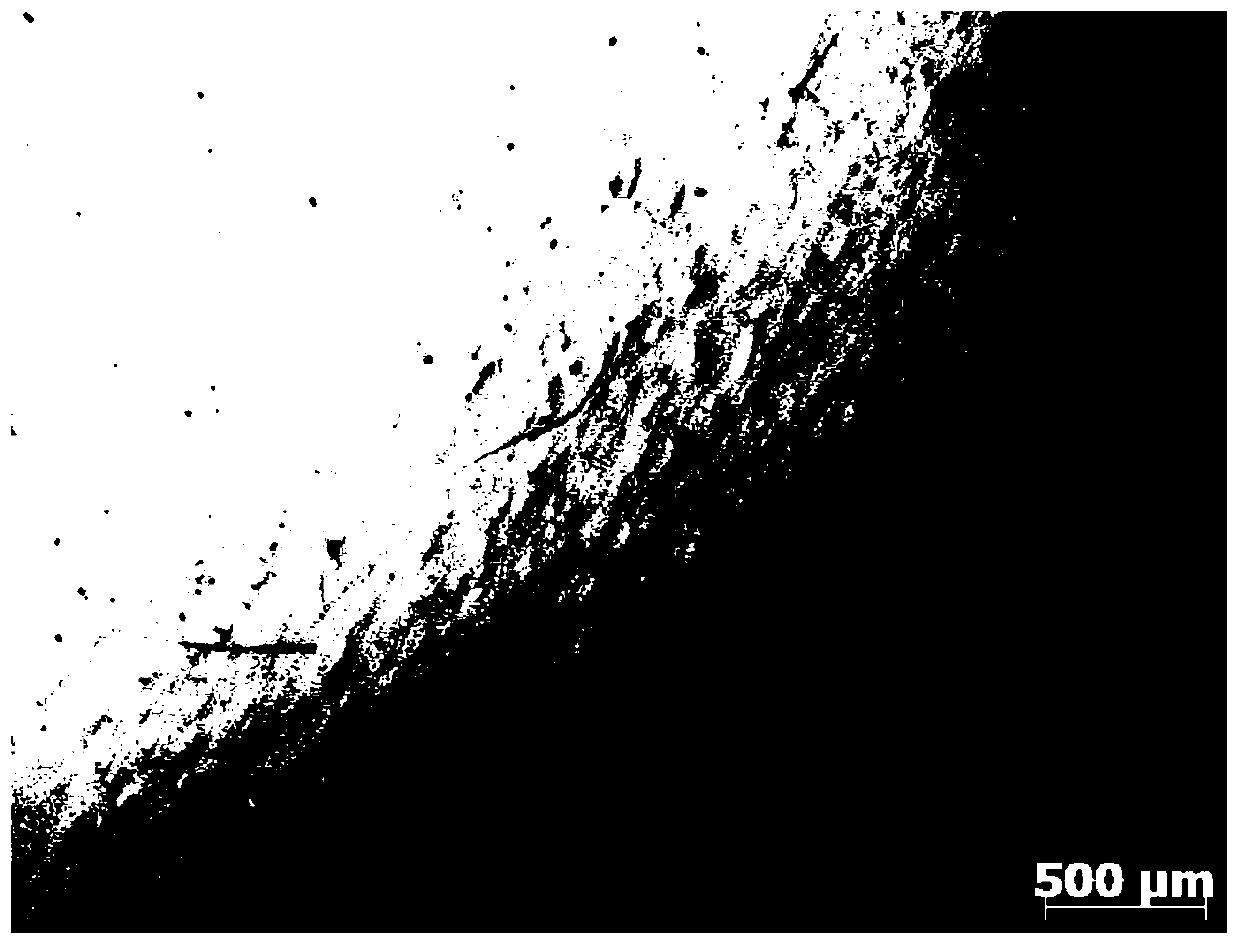

[0048] The composition of this embodiment is shown in Table 1. In this alloy, a certain amount of carbide-forming elements and rare earth elements are added to the original alloy composition (Table 2), wherein the total amount of Hf+Zr elements is 0.02%, and the weight of Ti+V accounts for 0.09%. , Ce / La is 1, O+N≤0.021%. By adding a small amount of carbide-forming elements, the content of carbides in superalloys is increased. In addition, by changing the size of the sample structure, the large-sized internal micropores in the alloy are reduced, and a certain amount of small-angle grain boundaries are formed, where L 1 Dimensions are 10mm, L 2 Dimensions are 0.5mm, H 1 Dimensions are 20mm, Y 1 The diameter is 0.5mm. Melt the paraffin wax at 50°C, inject the molten paraffin wax into the pre-designed metal mold with a heat preservation riser through the wax injection machine, and form the wax mold to complete the wax pattern combination, and put the assembled wax pattern thr...

Embodiment 2

[0058] The alloy composition of this embodiment is shown in Table 4. This alloy has added a certain amount of carbide forming elements and rare earth elements in the original alloy composition (Table 2), wherein the total amount of Hf+Zr elements is 0.06%, and the weight of Ti+V accounts for 0.3% %, Ce / La is 1.2, O+N≤0.021%. The difference from Example 1 is that the alloy composition in this example is characterized by the addition of carbide-forming elements to the upper limit, and the addition of rare earth elements to the upper limit. By adding a small amount of carbide-forming elements, the content of carbides in superalloys is increased. In addition, by changing the size of the sample structure, the large-sized internal micropores in the alloy are reduced, and a certain amount of small-angle grain boundaries are formed, where L 1 Dimensions are 10mm, L 2 Dimensions are 0.5mm, H 1 Dimensions are 20mm, Y 1 The diameter is 0.5mm. Melt the paraffin wax at 50°C, inject the...

Embodiment 3

[0065] The composition of the alloy in this example is the same as that in Example 2, and the structural size of the sample is adjusted so that solidification defects such as small-angle grain boundaries and internal micropores exist in the sample. The composition of this embodiment is shown in Table 6. This alloy adds a certain amount of carbide forming elements and rare earth elements to the original alloy composition (Table 2), wherein the total amount of Hf+Zr elements is 0.06%, and the weight of Ti+V accounts for 0.3%. , Ce / La is 1.2, O+N≤0.021%, and its composition is characterized by adding carbide-forming elements to the upper limit, and rare earth elements are also added to the upper limit. By adding a small amount of carbide-forming elements, the content of carbides in superalloys is increased. In addition, by changing the size of the sample structure, the large-sized internal micropores in the alloy are reduced, and a certain amount of small-angle grain boundaries a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com