TVS device based on SOI substrate and manufacturing method thereof

A substrate and device technology, which is applied in TVS devices based on SOI substrates and its manufacturing field, can solve the problems of unbalanced TVS, easy loss of high-frequency signals, large leakage current and large capacitance, etc. Low leakage current, low clamping voltage, effect of low clamping voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

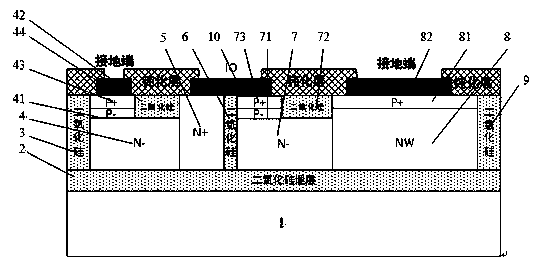

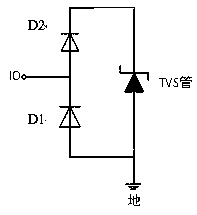

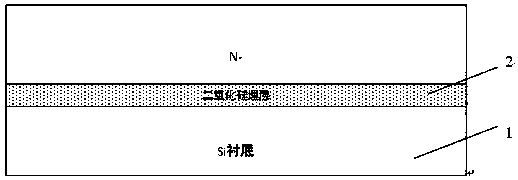

[0051] A TVS device based on SOI substrate, such as figure 1 As shown, an SOI substrate 1 is adopted, and its basic unit is composed of a silicon dioxide buried layer 2 and a deep groove of silicon dioxide to form an isolation layer. The surface of the silicon dioxide buried layer has a first silicon dioxide deep groove 3, The first N-region 4, the N+ region 5, the second silicon dioxide deep groove 6, the second N-region 7, the NW region 8 and the third silicon dioxide deep groove 9, wherein,

[0052] The thickness of the silicon dioxide buried layer is not less than 6000Å;

[0053] On the surface of the first N-region 4, there are doped first P-region 41, first silicon dioxide shallow groove 42 in sequence, and on the surface of the second N-region 7, there are doped second P-region 71, the first Silicon dioxide shallow groove 72, and doped on the first and second P-regions 41 and 71 surfaces to form first and second P+ regions 43 and 73 respectively, forming two P+ / P- / N- r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com