Circuit board with embedded capacitor and manufacturing method thereof

A manufacturing method and circuit board technology, applied to parts with fixed capacitance, removing conductive materials by chemical/electrolytic methods, containing printed capacitors, etc., can solve the problems of complex process, high cost, high dielectric constant, etc., and achieve The effect of cost reduction, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

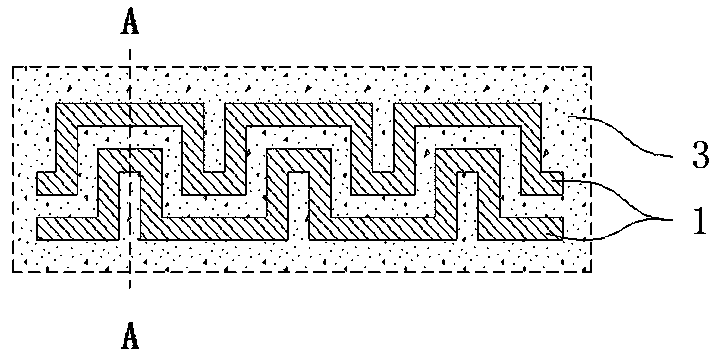

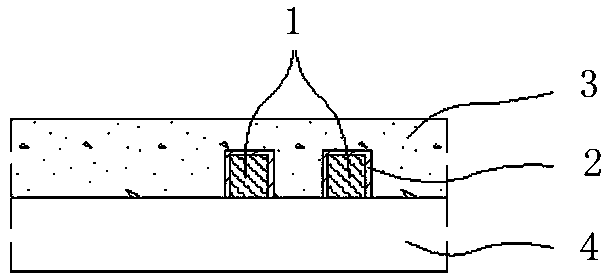

[0024] Such as figure 1 and figure 2 The circuit board manufacturing method with embedded capacitors shown is characterized in that it includes the steps of: wet film coating / dry film lamination, exposure, development, line etching, film removal, surface treatment, printing, and baking.

[0025] Specifically include the following steps:

[0026] Step A: Coating wet film / laminating dry film on the copper foil surface of the circuit board;

[0027] Step B: Exposing and developing to form the protective layer of the required ordinary circuit pattern and the parallel circuit of the capacitor plate;

[0028] Step C: removing the copper foil without protective layer by etching, leaving the required ordinary copper lines and the parallel lines 1 of the capacitor plates;

[0029] Step D: remove the film, remove the surface protection layer, and obtain the required ordinary circuit and the parallel circuit 1 of the capacitor plate;

[0030] Step E: Carrying out tinning surface tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com