Anode for secondary battery, manufacturing method therefor, and lithium secondary battery manufactured using same

A technology for secondary batteries and anodes, applied to anodes for secondary batteries and their manufacture, can solve the problems of reduced initial charge/discharge efficiency, shortened battery life, battery short-circuit, etc., to suppress the generation of dendrites, improve interface performance, The effect of prolonging the service life

Pending Publication Date: 2020-02-11

乐天能源材料公司

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, compared with the case of using lithium metal or lithium alloy as an anode active material, there are problems of lower capacity and lower initial charge / discharge efficiency

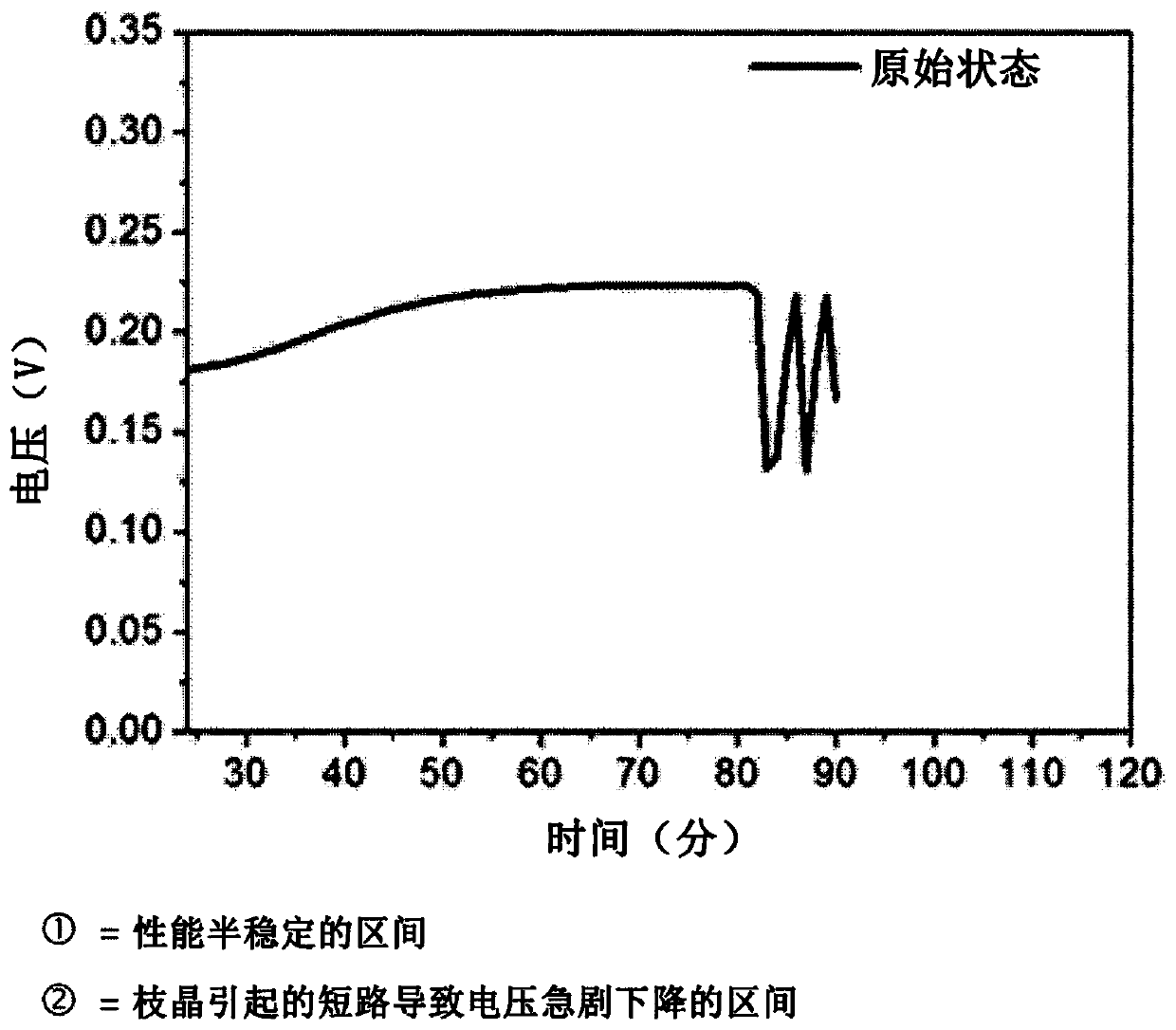

[0017] At the same time, if lithium metal or lithium alloy itself is used as an anode active material, it can indeed improve the electrochemical performance and have a large capacity, but the formation of a dendrite structure will cause a short circuit in the battery, which will not only shorten the battery life, but even worse, Can cause safety issues such as battery explosion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

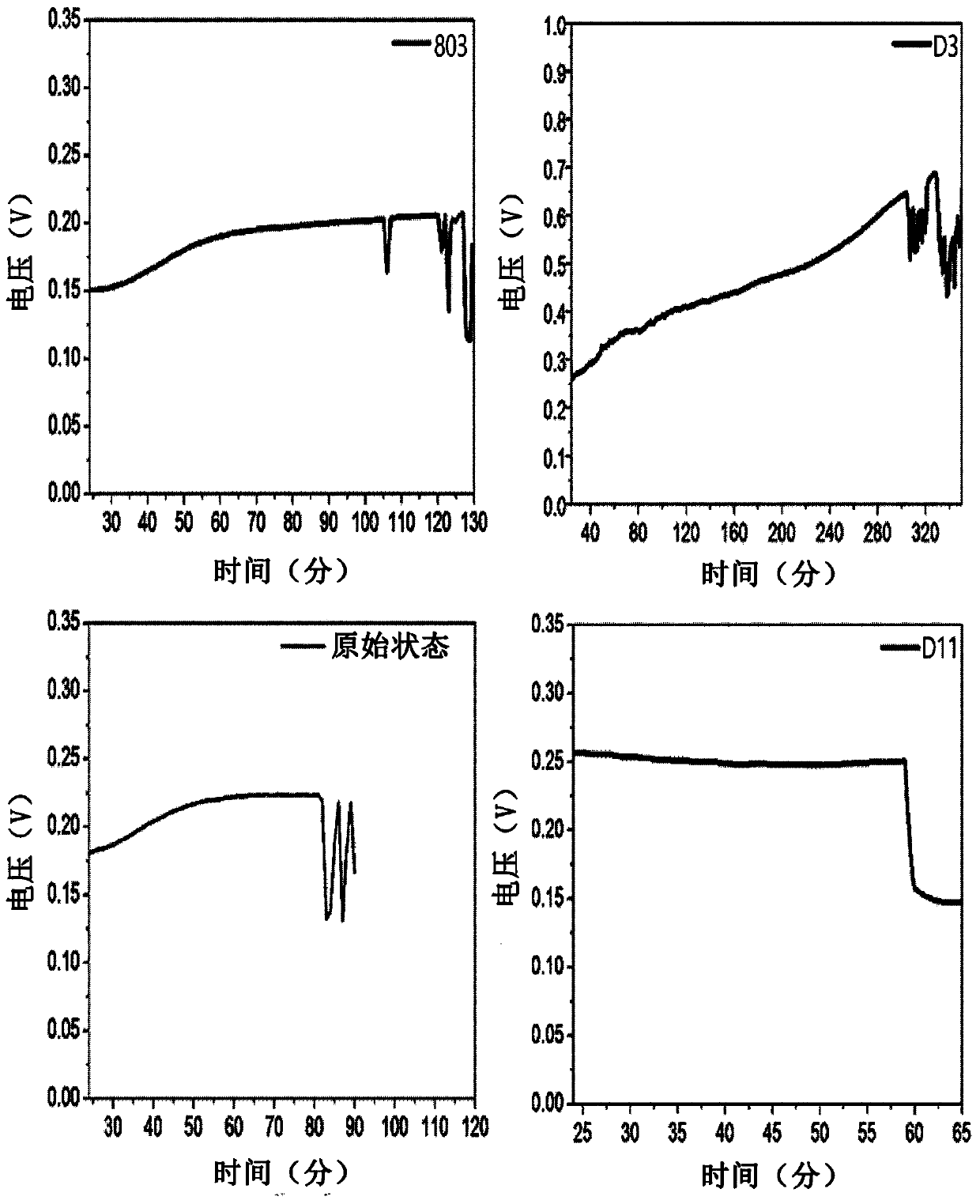

[0128] 6. Example 2, Example 3 and Example 4

[0129] As shown in Tables 1 and 2, except that the thickness of the lithium powder active material electrode is different and the thickness and tensile strength of the electrolytic copper foil current collector (copper current collector) as the current collector are different, Examples 2 and 4 are different from Example 1 Experiment in the same way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to an anode for a secondary battery, a manufacturing method therefor, and a lithium secondary battery using the same, the anode comprising: an electrolytic copper foil current collector; an anode active material layer provided on one surface or both surfaces of the electrolytic copper foil current collector, and including lithium powder; and a protective layer provided on the anode active material layer, wherein the thickness of the electrolytic copper foil current collector is 2 [mu]m to 20 [mu]m, and the thickness of the anode active material layer and the protective layer provided on the electrolytic copper foil current collector is 100 [mu]m or less.

Description

technical field [0001] Unlike primary batteries (such as batteries that are discarded after one-time use), secondary batteries are rechargeable batteries, and there are many types, such as lead-acid batteries, nickel-cadmium batteries, and nickel-metal hydride batteries. Typically, batteries are named according to the material used for their electrodes, for example, a lead battery uses lead as the anode so that the lead causes a redox reaction during charge / discharge; a nickel-cadmium battery is a battery that uses cadmium as the anode; nickel metal hydride The battery is a battery that uses a nickel metal hydride alloy as an anode. [0002] The secondary lithium battery is one of the most advanced secondary batteries. Lithium ions can participate in the redox reaction of its anode. Moreover, the density of lithium metal is 0.53g / cm 3 , is the lightest alkali metal existing on the earth, and its required standard redox potential is also the lowest. In view of these character...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/134H01M4/66H01M4/38H01M4/62H01M4/1395H01M4/04H01M10/052

CPCH01M4/134H01M4/1395H01M4/382H01M4/661H01M4/0404H01M4/62H01M4/628H01M10/052H01M2004/021H01M2004/028H01M4/366Y02E60/10H01M4/0435H01M4/0416H01M4/13H01M10/0525

Inventor 李先珩崔恩实赵泰真金亨哲宋基德

Owner 乐天能源材料公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com