Reaction kettle for biological pharmacy

A technology of biopharmaceuticals and reactors, applied in chemical/physical processes, dissolution, mixers, etc., can solve the problems of uneven mixing of drug raw materials, easy contamination of drug raw materials, and affecting work efficiency, so as to facilitate sampling work and avoid blockage , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

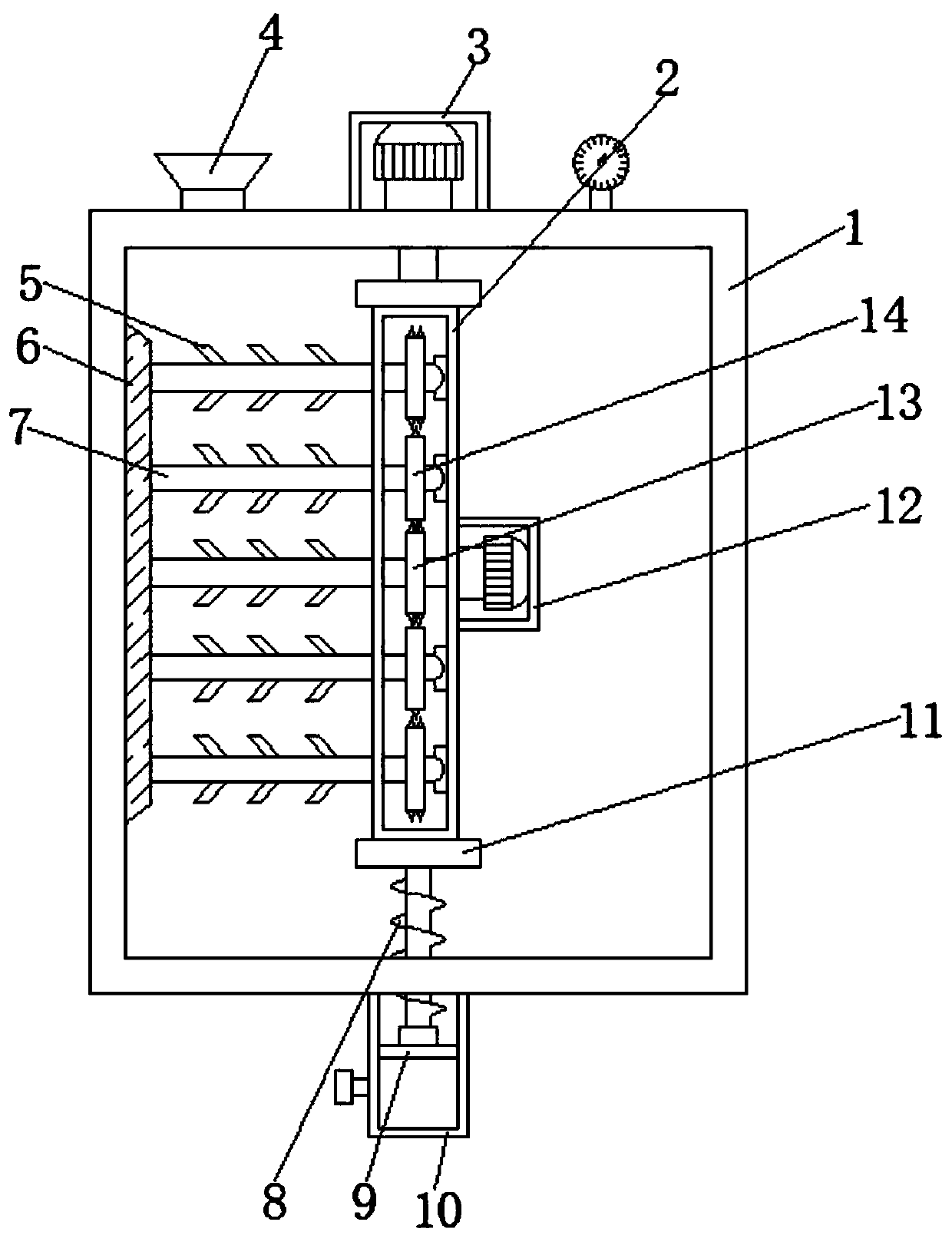

[0025] refer to Figure 1-2 , a reaction kettle for biopharmaceuticals, comprising a kettle body 1, a round hole is opened on the top outer wall of the kettle body 1, and a feed hopper 4 is welded in the round hole, and a first protective shell is connected to the top outer wall of the kettle body 1 by bolts 3, and the top inner wall of the first protective shell 3 is connected with the first motor by bolts, and the outer wall of one end of the output shaft of the first motor is welded with a mounting plate, and the mounting plate is connected with the fixed pipe 2 by bolts, and the outer wall of one side of the fixed pipe 2 The second protective case 12 is connected by bolts, and the inner wall of one side of the second protective case 12 is connected with the second motor by bolts, and the outer wall of one end of the output shaft of the second motor is welded with the stirring rod 7, and the peripheral outer wall of the stirring rod 7 is covered with Connected with driving ...

Embodiment 2

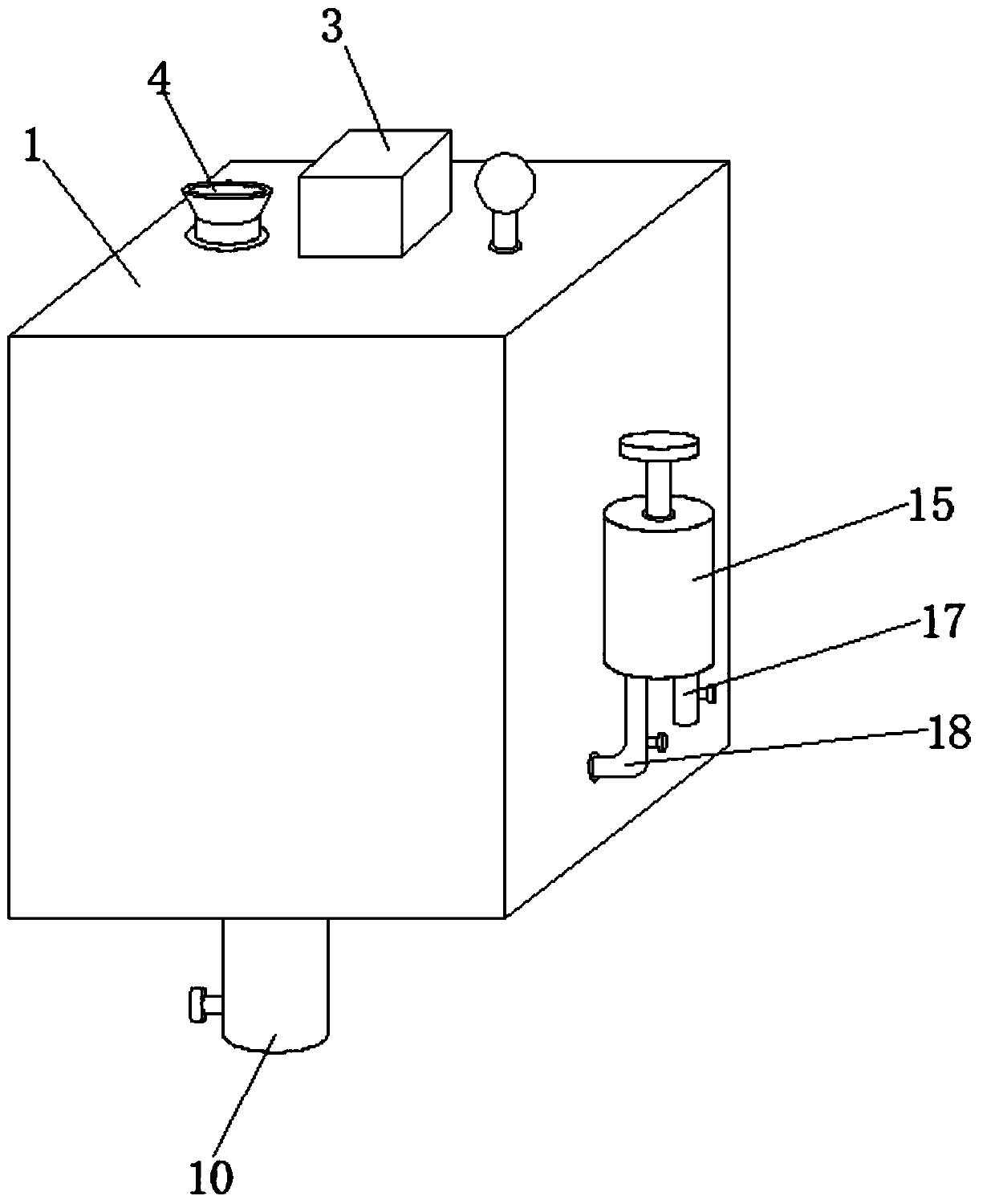

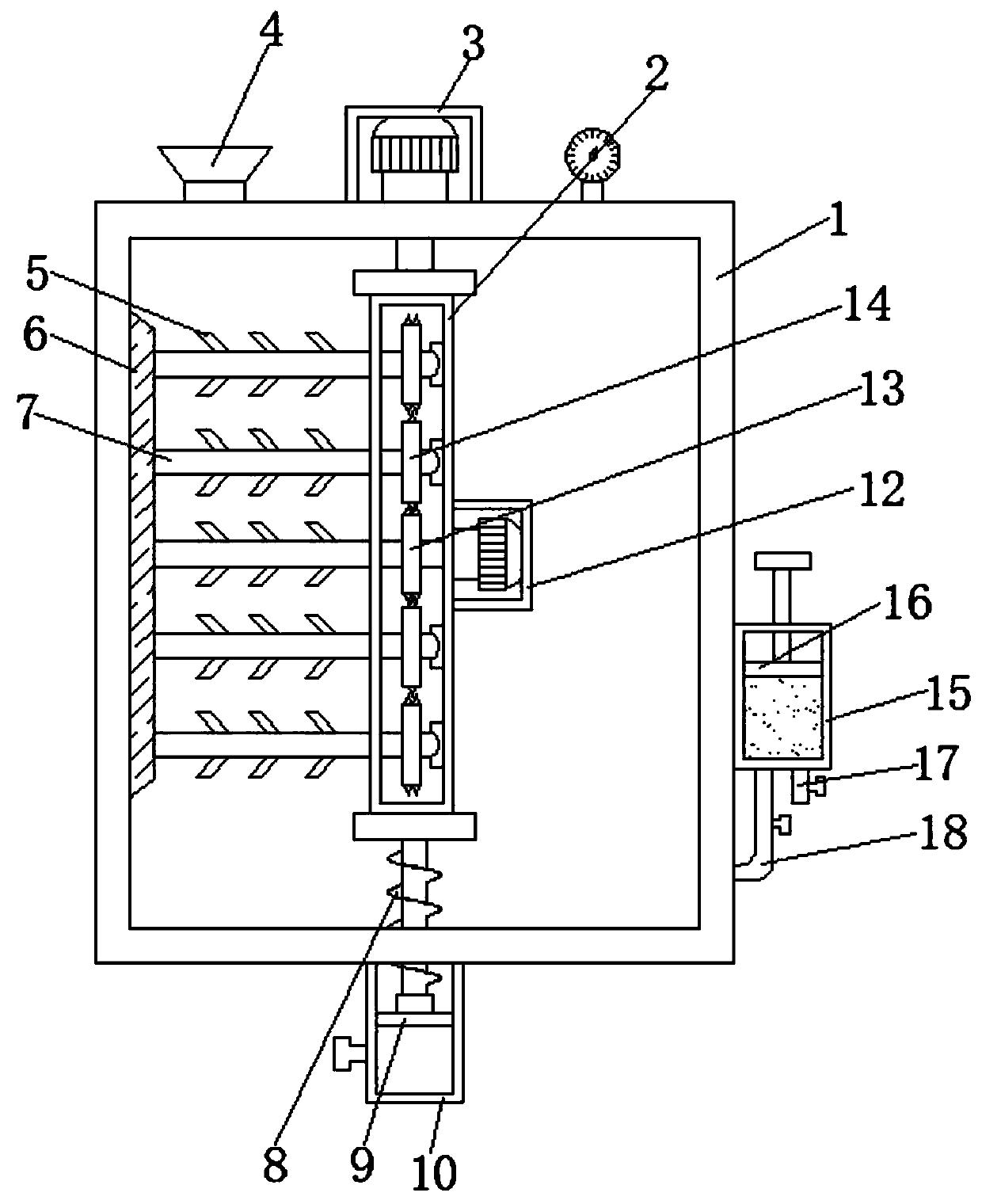

[0029] refer to image 3 , a reaction kettle for biopharmaceuticals. Compared with Example 1 in this embodiment, a sampling cylinder 15 is connected to one side of the outer wall of the kettle body 1 through bolts, and a drawing rod is inserted into the top inner wall of the sampling cylinder 15. The drawing rod The outer wall of one end is provided with a piston 16, and the outer wall of the bottom of the sampling cylinder 15 is respectively inserted with a sampling pipe 18 and a connecting pipe 17, and the outer wall of one side of the sampling pipe 18 and the connecting pipe 17 is respectively connected with a first control valve and a second control valve through bolts. Valve, the end of the sampling tube 18 away from the sampling cylinder 15 extends to the inside of the kettle body 1 .

[0030] Working principle: when in use, people add materials into the kettle body 1 through the feed pipe 4, and the staff start the first motor and the second motor respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com