Device and method for generating alkylene oxide through reaction of alkylbenzene peroxide and low-carbon olefin

A technology for alkylbenzene peroxides and low-carbon olefins, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc. Frequent replacement of catalysts and other issues, to achieve the effect of prolonging catalyst life, uniform distribution of reactant concentration, and prolonging operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

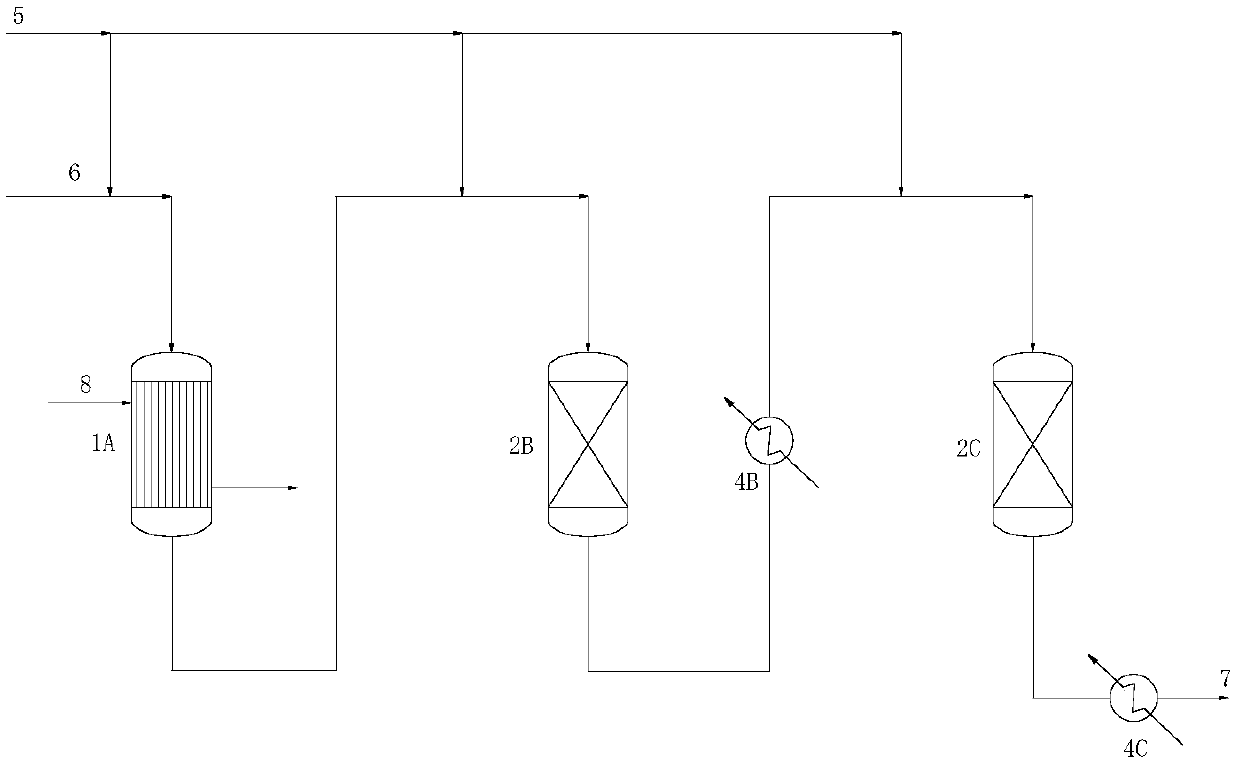

[0046] use as figure 1 The shown device for reacting alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides reacts alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides.

[0047] Such as figure 1 As shown, the device includes three reactors in series, which are successively the first epoxidation reactor 1A, the second epoxidation reactor 2B and the third epoxidation reactor 2C, wherein the first epoxidation reactor 1A is a tubular isothermal bed reactor, the second epoxidation reactor 2B and the third epoxidation reactor 2C are adiabatic bed reactors; the first epoxidation reactor 1A is provided with a heat removal medium inlet and outlet pipeline, The discharge pipeline of the first epoxidation reactor 1A directly connects the second epoxidation reactor 2B; the discharge pipeline of the second epoxidation reactor 2B connects the second reaction discharge cooler 4B and then connects the third loop Oxidation reactor 2C, the discharge p...

Embodiment 2

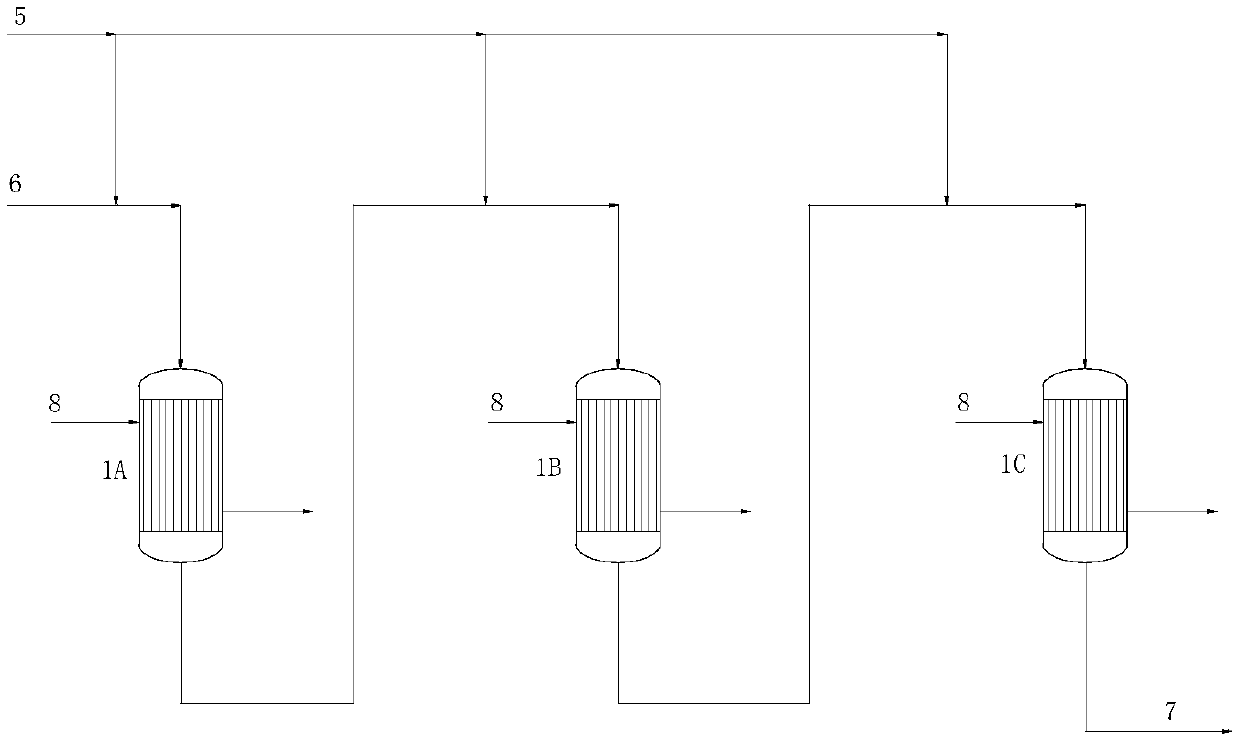

[0053] use as figure 2 The shown device for reacting alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides reacts alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides. Different from Example 1, the three reactors connected in series are the first epoxidation reactor 1A, the second epoxidation reactor 1B, and the third epoxidation reactor 1C, and the three reactors are all tubes. isothermal bed reactor.

[0054] The same reactor operating conditions as in Example 1 were used. The selectivity of the alkylbenzene peroxide in the main reaction is 99.6%, and the conversion rate is 99.5%.

Embodiment 3

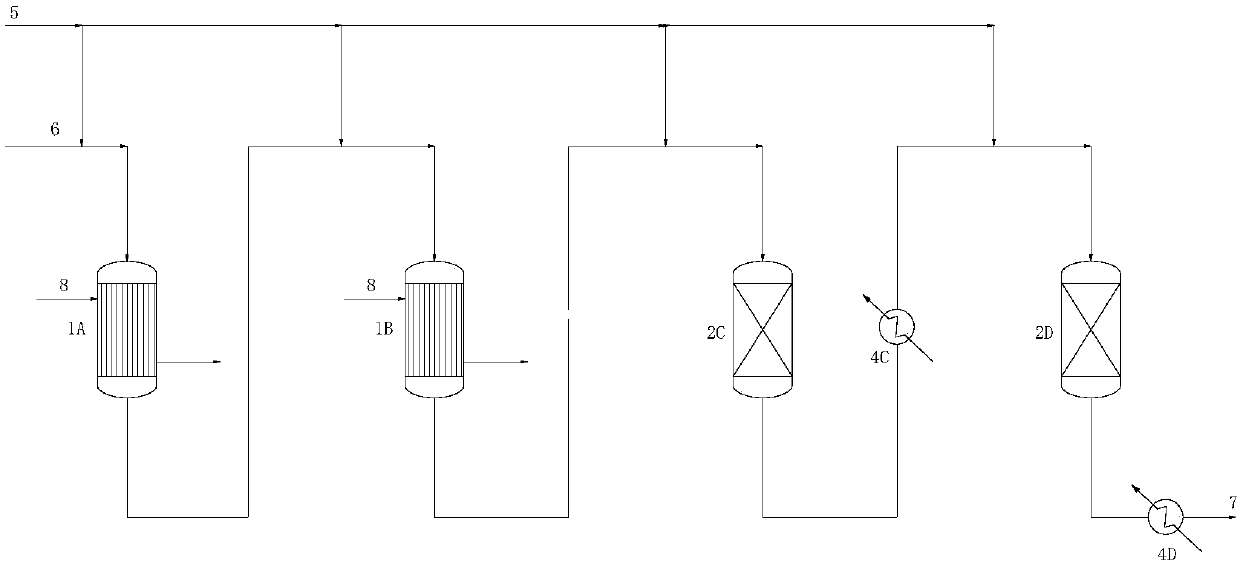

[0056] use as image 3 The shown device for reacting alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides reacts alkylbenzene peroxides with low-carbon olefins to generate alkylene oxides. The difference from Example 1 is that the four reactors connected in series are sequentially a tube-and-tube isothermal bed reactor, a tube-and-tube isothermal bed reactor, an adiabatic bed reactor and an adiabatic bed reactor.

[0057] The same reactor operating conditions as in Example 1 were used. The selectivity of the alkylbenzene peroxide in the main reaction is 95%, and the conversion rate is 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com