Method for producing C40 concrete

A production method and technology for concrete, applied in the field of concrete, can solve the problems of reducing the control and durability of concrete cracks, difficult to ensure the performance requirements of self-consolidating concrete workability, increasing shrinkage value, etc., to reduce insufficient hydration, Improved crack control and durability, improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

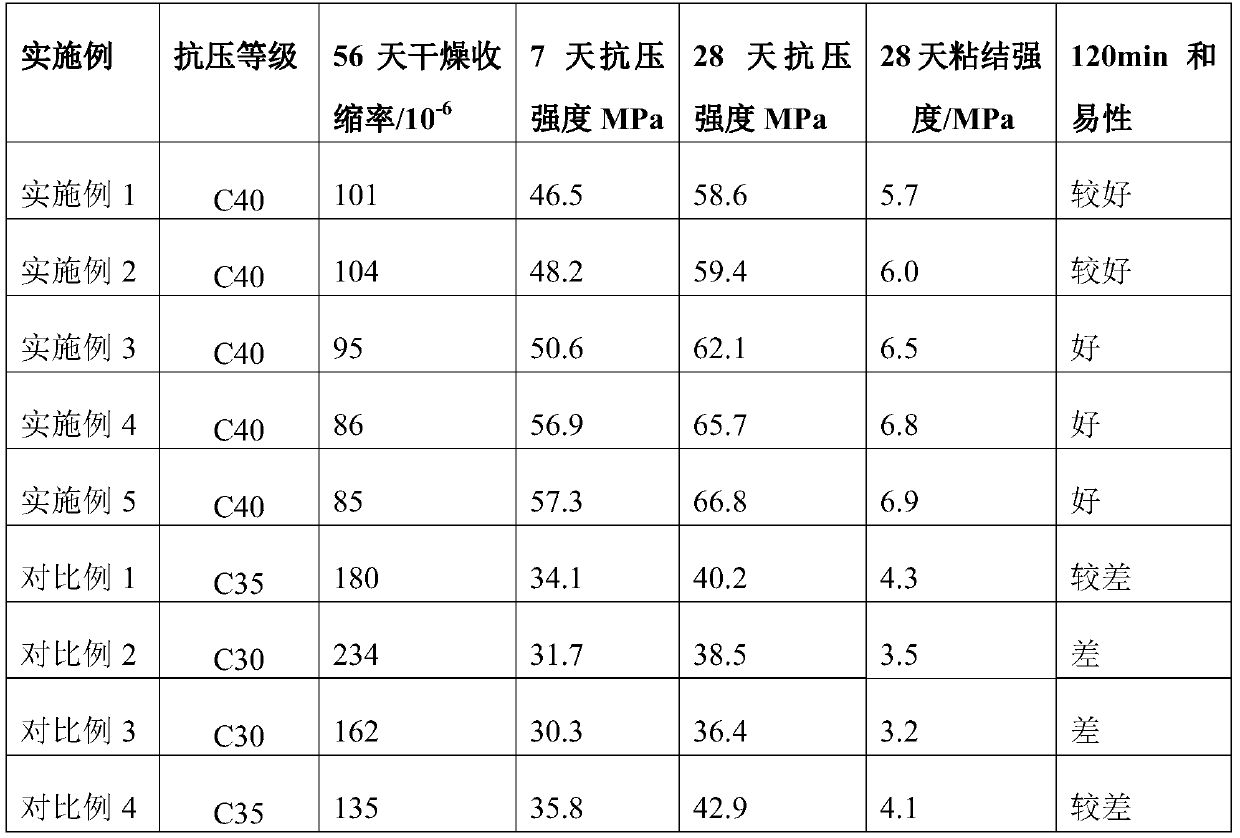

Examples

Embodiment 1

[0034] Embodiment 1-a kind of production method of C40 concrete, comprises the steps:

[0035] (1) Raw material formula

[0036] By weight, the preparation of concrete per cubic meter includes the following weight raw materials: 230Kg of cement, 95g of fly ash, 160kg of water, 830kg of sand, 935kg of bluestone, 120kg of mineral powder, 8kg of composite water reducing agent and 12kg of mixed fiber;

[0037] The composite water reducer, by mass percentage, includes: polycarboxylate water reducer 13%, aliphatic water reducer 5%, reinforcing agent 1%, expansion agent 0.5%, anti-settling agent 0.3%, defoamer 0.02% and the balance is water; the mixed fiber is a mixture of alumina fine powder, short carbon fiber, polyethylene long fiber and coconut shell fiber, and the weight ratio is 1:1:1:2; short carbon fiber is 5-8mm, polyethylene The long fiber is 25-30mm, the coconut shell fiber is 10-15mm; the particle size of the alumina fine powder is 0.25-0.55mm; %6mm~10mm, 35%11mm~15mm, ...

Embodiment 2

[0043] Example 2 - a production method of C40 concrete, the difference from Example 1 is that the raw material formula is: cement 240Kg, fly ash 105g, water 170kg, sand 840kg, bluestone 955kg, mineral powder 130kg, composite water reducer 10kg and mixed fiber 18kg;

[0044]The composite water reducer includes, by mass percentage: 13-15% polycarboxylate water reducer, 6% aliphatic water reducer, 5% reinforcing agent, 1.0% expansion agent, 0.5% anti-settling agent, defoamer 0.04% and the balance is water; the mixed fiber is a mixture of alumina fine powder, short carbon fiber, polyethylene long fiber and coconut shell fiber, and the weight ratio is 1:2:2:2; the short carbon fiber is 5-8mm, The polyethylene long fiber is 25-30mm, the coconut shell fiber is 10-15mm; the particle size of the alumina fine powder is 0.25-0.55mm; the bluestone is crushed until the particle size gradation is: 5% 3-5mm , 35% 6mm ~ 10mm, 35% 11mm ~ 15mm, 15% 16mm ~ 20mm, 10% 21 ~ 25mm;

[0045] The ant...

Embodiment 3

[0047] Embodiment 3-a production method of C40 concrete, the difference from Example 1 is that the raw material formula is: cement 235Kg, fly ash 100g, water 165kg, sand 835kg, bluestone 940kg, mineral powder 125kg, composite water reducer 9.5 kg and mixed fiber 15.5kg;

[0048] The composite water reducer, by mass percentage, includes: polycarboxylate water reducer 14%, aliphatic water reducer 5.5%, reinforcing agent 3%, expansion agent 0.65%, anti-settling agent 0.4%, defoamer 0.03% and the balance is water; the mixed fiber is a mixture of alumina fine powder, short carbon fiber, polyethylene long fiber and coconut shell fiber, and the weight ratio is 1:3:3:2; short carbon fiber is 5-8mm, polyethylene The long fiber is 25-30mm, the coconut shell fiber is 10-15mm; the particle size of the alumina fine powder is 0.25-0.55mm; %6mm~10mm, 35%11mm~15mm, 15%16mm~20mm, 10%21~25mm;

[0049] The anti-sedimentation agent is cellulose ether CMC; the label of the cement is 425#; the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com