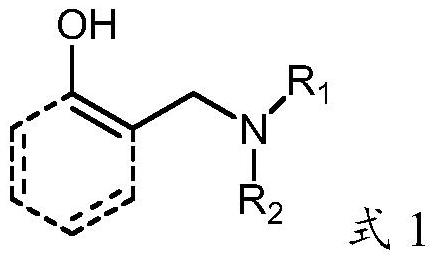

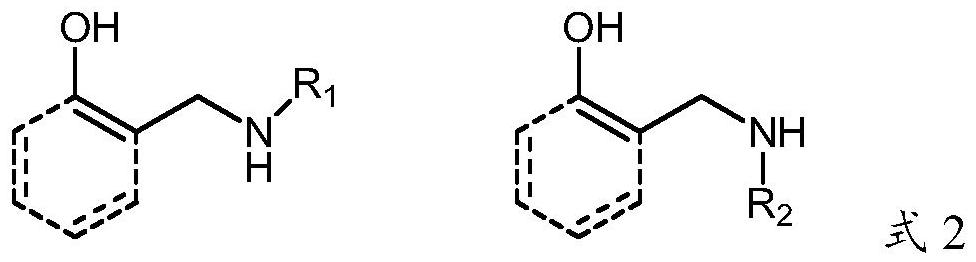

A kind of preparation method of tdi trimer and solvent-containing tdi trimer and its application

A trimer and solvent technology, applied in the field of polyisocyanate, can solve the problems of poor aging resistance and yellowing resistance of paint films or adhesive films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

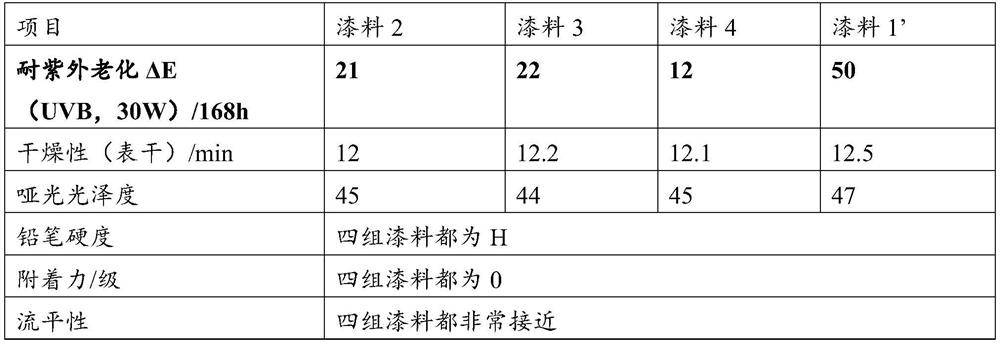

Examples

Embodiment 1

[0070] 1. Purification of Mannich base

[0071] The solid Mannich base catalyst based on bisphenol A / formalin / dimethylamine was synthesized with reference to US 4115373.

[0072]At 90°C, gradually add the catalyst to butyl acetate until saturated, quickly transfer the saturated solution of the catalyst to -20°C, and place it for 12 hours, the catalyst precipitates, the solution is filtered to obtain the purified solid catalyst, and in Dry at 30°C / 0.6mbar.

[0073] The dried catalyst (the impurity content of the secondary amine is about 1000ppm) is dissolved in xylene to form a xylene solution for subsequent use.

[0074] 2. Preparation of TDI trimer

[0075] 500g of TDI-80 as the starting diisocyanate and 500 g of butyl acetate were mixed in a 2 L reaction vessel purged with nitrogen to obtain a reaction mixture; the reaction mixture was heated to the required reaction temperature of 75° C. 1.5 g of a polymerization catalyst solution (the solution is a xylene solution of ...

Embodiment 2

[0083] 1. Purification of Mannich base

[0084] The solid Mannich base catalyst based on bisphenol A / formalin / dimethylamine was synthesized with reference to US 4115373.

[0085] At 75°C, gradually add the catalyst to butyl acetate until saturated, quickly transfer the saturated solution of the catalyst to -20°C, and place it for 12 hours, the catalyst precipitates, and the solution is filtered to obtain the purified solid catalyst, and in Dry at 30°C / 0.6mbar.

[0086] Dissolve the dried catalyst (secondary amine impurity content is about 500ppm) in xylene to form a xylene solution for subsequent use.

[0087] 2. Preparation of TDI trimer

[0088] 500g of TDI-80 as the starting diisocyanate and 500 g of butyl acetate were mixed in a 2 L reaction vessel purged with nitrogen to obtain a reaction mixture; the reaction mixture was heated to the required reaction temperature of 75° C. 1.5 g of a polymerization catalyst solution (the solution is a xylene solution of Mannich bas...

Embodiment 3

[0096] 1. Purification of Mannich base

[0097] The liquid Mannich base catalyst based on phenol / formalin / dimethylamine is synthesized with reference to US 4115373.

[0098] The synthesized Mannich base catalyst is subjected to short-path distillation to obtain the purified Mannich base catalyst. Conditions: 180°C / 0.1mbar, feed 0.5Kg / h, evaporation area 0.05m 2 .

[0099] The catalyst (secondary amine impurity content is about 500ppm) collected by distillation was dissolved in butyl acetate to form a butyl acetate solution for subsequent use.

[0100] 2. Preparation of TDI trimer

[0101] 500g of TDI-80 as the starting diisocyanate and 500 g of butyl acetate were mixed in a 2 L reaction vessel purged with nitrogen to obtain a reaction mixture; the reaction mixture was heated to the required reaction temperature of 75° C. 1.5 g of a polymerization catalyst solution (the solution is a butyl acetate solution of Mannich base, the catalyst concentration in which is 40 wt %) wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com