Visual constant volume combustion bomb device and method with controllable turbulent flow-flame blast wave effect

A constant-volume incendiary bomb and constant-volume combustion technology, which is applied to measuring devices, internal combustion engine tests, engine tests, etc., can solve the problems of inability to accurately infer the turbulent flow movement in the cylinder and the spontaneous combustion state of the end, and achieve simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

[0039] The present invention proposes a controllable turbulence-flame shock wave action visual constant volume incendiary device, including a constant volume combustion device, a fuel supply system, a heating system, an ignition system, a high-speed photography system, an intake and exhaust system, and pressure acquisition in a cylinder system and synchronous controller.

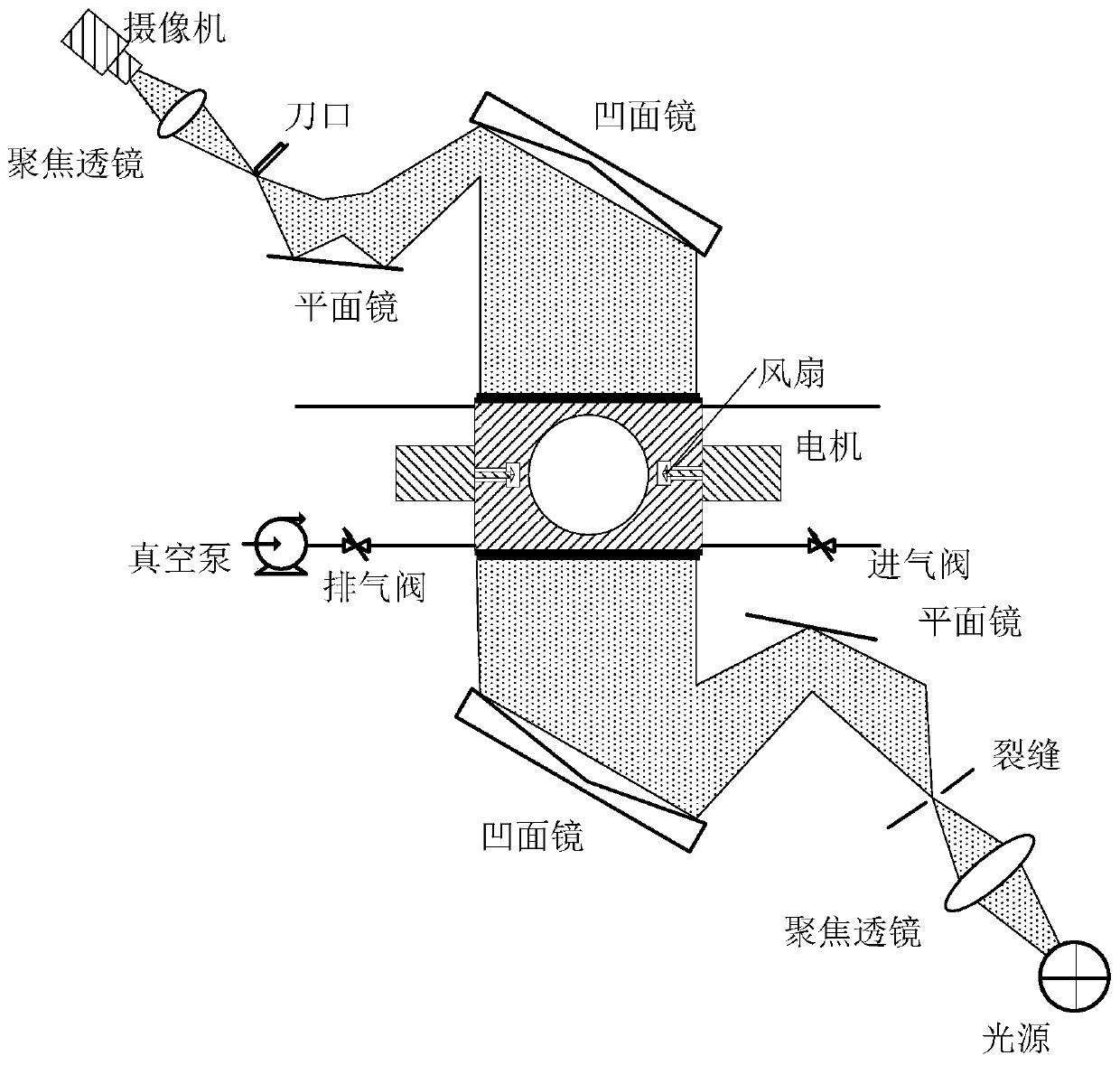

[0040] Such as figure 1 As shown, the constant volume projectile is located at figure 1 In the center, there are vacuum pumps, exhaust valves, and intake valves on the left and right sides respectively. The light is first emitted by the light source, focused by the focusing lens on the lower right, and then passes through the crack to the plane mirror, and then is reflected by the plane mirror to the concav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com